PWM v2.1 plans

Detailed plans to build devices for HHO, HOH, HOD, PWM pulse width modulators, and EFIE electronic fuel injection enhancers.

The schematic for constructing devices related to HHO (Hydrogen-Hydrogen-Oxygen) production, HOH (Water), HOD (Hydrogen-Oxygen-Diatomic), PWM (Pulse Width Modulation) controllers, and EFIE (Electronic Fuel Injection Enhancer) requires careful consideration of various electronic components and their interconnections.

For HHO generation, the circuit typically includes a power supply, often a DC source, connected to a series of electrolytic cells. Each cell consists of two electrodes—an anode and a cathode—immersed in an electrolyte solution. The choice of electrolyte, commonly potassium hydroxide (KOH) or sodium hydroxide (NaOH), can significantly affect the efficiency of hydrogen production. The circuit must also incorporate safety features such as fuses and relays to prevent overcurrent conditions.

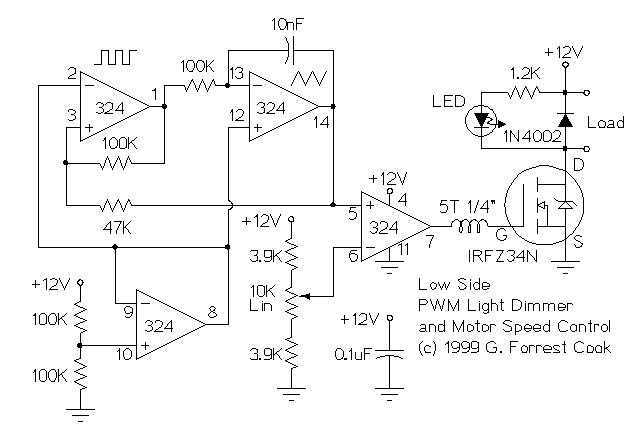

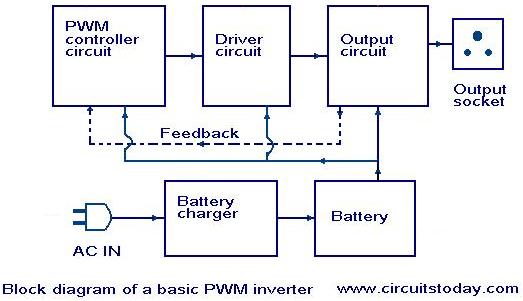

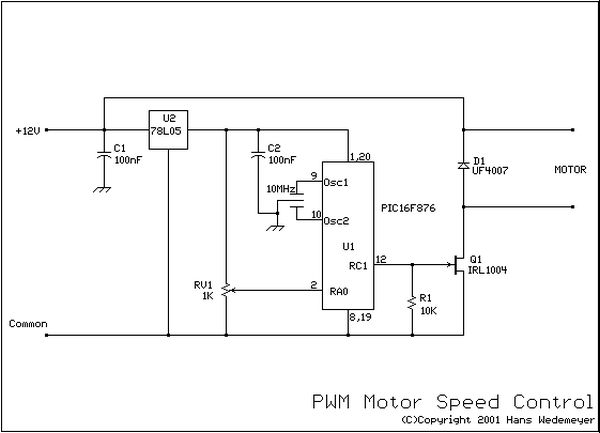

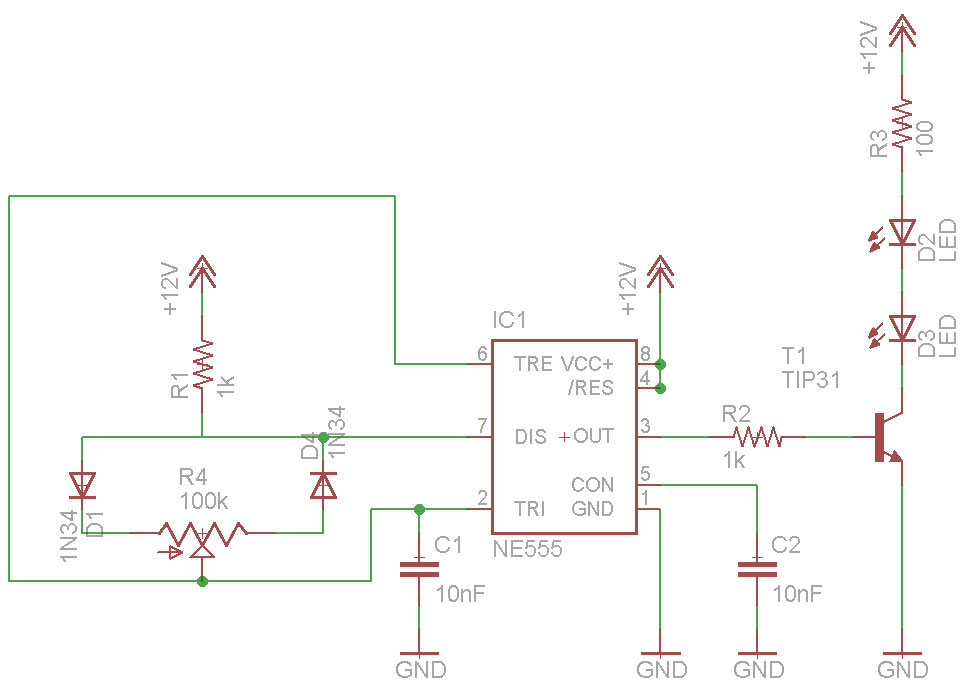

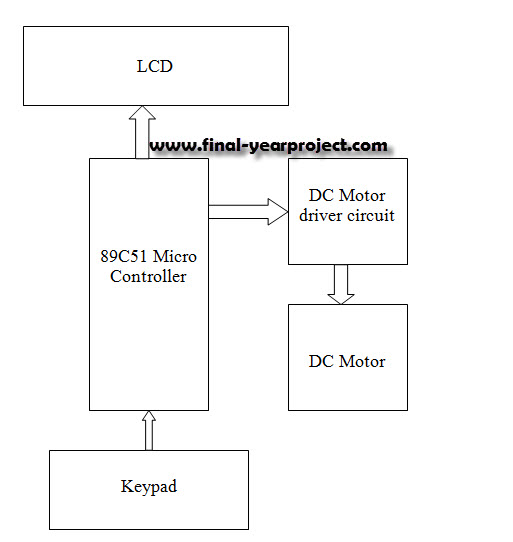

The PWM controller is crucial for regulating the power supplied to the electrolytic cells. This involves using a microcontroller or a dedicated PWM IC to modulate the duty cycle of the voltage supplied to the cells, which optimizes gas production while minimizing energy consumption. The PWM signal is typically generated using a combination of resistors, capacitors, and transistors configured in an astable multivibrator or through software in a microcontroller.

The EFIE circuit enhances fuel injection by modifying the signal sent to the fuel injectors, thereby improving combustion efficiency. This circuit often includes an operational amplifier configured to adjust the voltage levels based on feedback from the vehicle's oxygen sensors. Proper calibration is essential to ensure that the modified signals lead to improved fuel efficiency without triggering error codes in the vehicle's onboard diagnostics.

Overall, the integration of these components requires a thorough understanding of both electrical engineering principles and the specific requirements of each device. Proper layout and grounding techniques are essential to minimize noise and ensure stable operation. Additionally, safety precautions must be observed when working with hydrogen production due to its flammability and the potential for explosive mixtures.detailed plans to build devices for HHO, HOH, HOD, PWM pulse width modulators, EFIE electronif fuel injection enhancer, etc. 🔗 External reference

The schematic for constructing devices related to HHO (Hydrogen-Hydrogen-Oxygen) production, HOH (Water), HOD (Hydrogen-Oxygen-Diatomic), PWM (Pulse Width Modulation) controllers, and EFIE (Electronic Fuel Injection Enhancer) requires careful consideration of various electronic components and their interconnections.

For HHO generation, the circuit typically includes a power supply, often a DC source, connected to a series of electrolytic cells. Each cell consists of two electrodes—an anode and a cathode—immersed in an electrolyte solution. The choice of electrolyte, commonly potassium hydroxide (KOH) or sodium hydroxide (NaOH), can significantly affect the efficiency of hydrogen production. The circuit must also incorporate safety features such as fuses and relays to prevent overcurrent conditions.

The PWM controller is crucial for regulating the power supplied to the electrolytic cells. This involves using a microcontroller or a dedicated PWM IC to modulate the duty cycle of the voltage supplied to the cells, which optimizes gas production while minimizing energy consumption. The PWM signal is typically generated using a combination of resistors, capacitors, and transistors configured in an astable multivibrator or through software in a microcontroller.

The EFIE circuit enhances fuel injection by modifying the signal sent to the fuel injectors, thereby improving combustion efficiency. This circuit often includes an operational amplifier configured to adjust the voltage levels based on feedback from the vehicle's oxygen sensors. Proper calibration is essential to ensure that the modified signals lead to improved fuel efficiency without triggering error codes in the vehicle's onboard diagnostics.

Overall, the integration of these components requires a thorough understanding of both electrical engineering principles and the specific requirements of each device. Proper layout and grounding techniques are essential to minimize noise and ensure stable operation. Additionally, safety precautions must be observed when working with hydrogen production due to its flammability and the potential for explosive mixtures.detailed plans to build devices for HHO, HOH, HOD, PWM pulse width modulators, EFIE electronif fuel injection enhancer, etc. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713