Pyro Propeller Clock POV Circuit

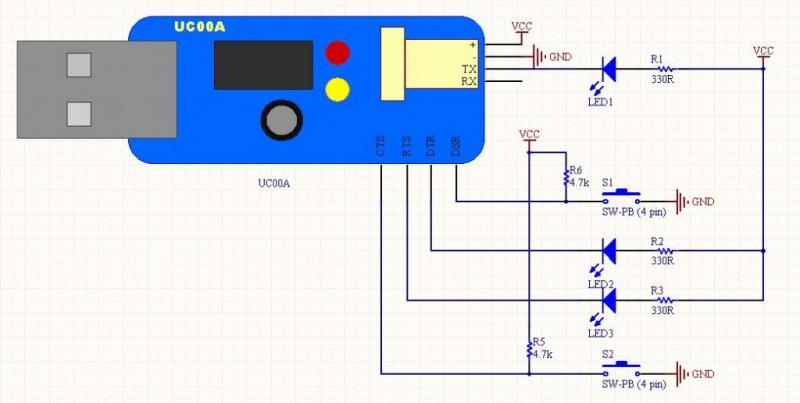

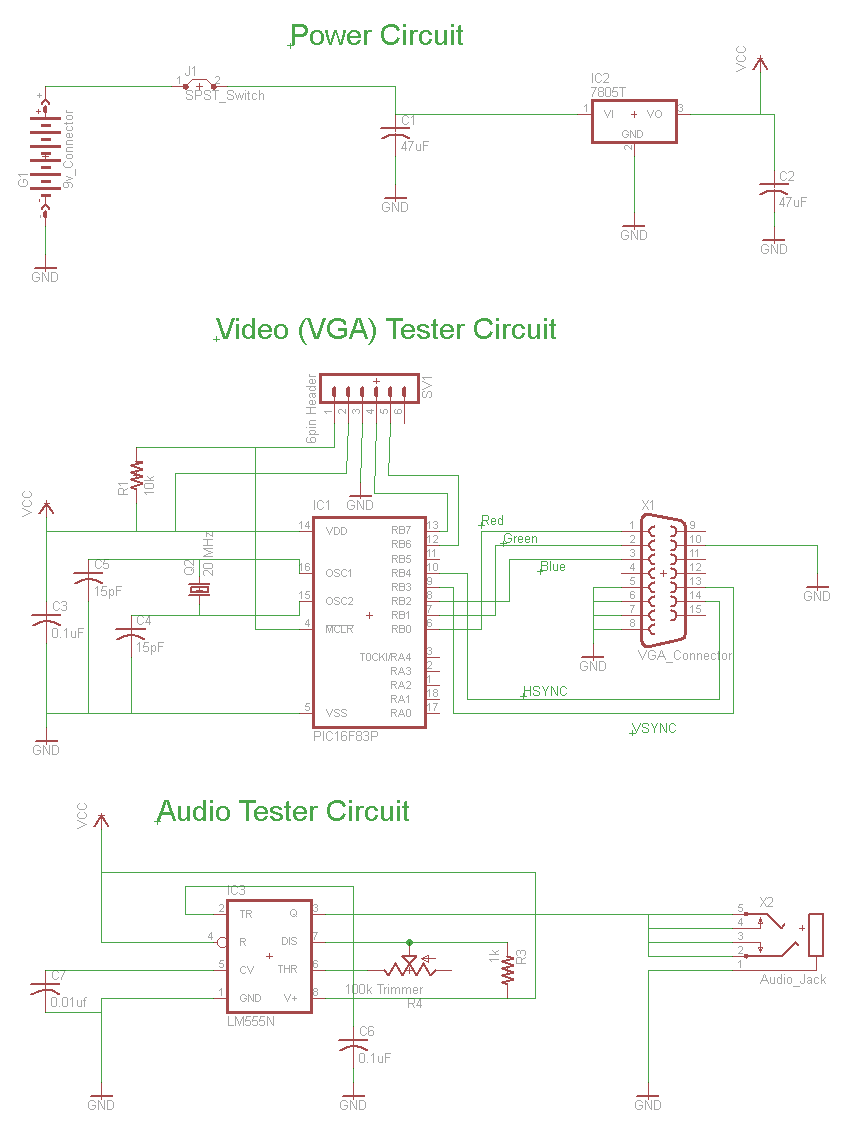

The Pyro Propeller Clock POV schematic is relatively straightforward. It consists of three primary components: the power supply utilizing a 7805 voltage regulator, the LED output control managed by a PIC18F252 microcontroller and a 74LS373 latch, and the 'home' trigger circuit that incorporates an IR emitter and phototransistor. The standard +5V power regulation circuit employs the LM7805 3-pin device. A DC filtering capacitor is connected to its output to mitigate high-frequency spikes from the power supply. The PIC18F252 operates with an 8-bit data bus system and two control lines to indicate which 74LS373 latch should output data to activate or deactivate the LEDs. This design allows data to be sent to one 74LS373 at a time, resulting in LED output updates that are nearly simultaneous rather than perfectly simultaneous. To determine when the system should restart displaying the current image on the propeller clock, a known reference point called 'home' is required. An IR emitter diode projects light onto a phototransistor, which turns 'on' and connects the +5V collector pin to the +0V emitter pin. The PIC18F252 detects this 'falling edge' transition, indicating that it has returned to the home position at 360°.

The Pyro Propeller Clock POV (Persistence of Vision) schematic is designed to facilitate a captivating visual display by employing a combination of electronic components that work in unison. The power supply section, based on the LM7805 voltage regulator, ensures a stable +5V output necessary for the operation of the entire circuit. The inclusion of a DC filtering capacitor serves to smooth out any voltage spikes, ensuring the reliability of the power supply under varying load conditions.

The LED output control is a critical aspect of the design, utilizing the PIC18F252 microcontroller, which is programmed to manage the data flow to the LEDs through the 74LS373 latches. The microcontroller's 8-bit data bus allows for efficient communication with the latches, while the two control lines facilitate the selection of which latch is currently active. This method of operation, where only one latch is addressed at a time, is advantageous as it simplifies the control logic and reduces the complexity of the circuit. The result is a nearly simultaneous update of the LED outputs, creating the illusion of a continuous image when the propeller spins.

The 'home' trigger circuit is essential for maintaining the synchronization of the displayed image. The IR emitter diode emits infrared light, which is detected by the phototransistor. When the IR light is interrupted, the phototransistor switches on, creating a transition from high to low voltage at its collector pin. This transition is detected by the PIC18F252, signaling that the propeller has completed a full rotation and returned to the home position. This feedback mechanism is crucial for ensuring the correct timing and alignment of the visual display, enabling the clock to maintain accurate image representation as it spins.

Overall, the Pyro Propeller Clock POV schematic exemplifies a well-thought-out design that integrates power management, data handling, and position sensing to produce a visually striking display. The careful selection of components and their arrangement within the circuit contribute to the effectiveness and reliability of the final product.The Pyro Propeller Clock POV schematic is actually not very difficult. There are three main parts: the power supply which uses a 7805, the LED output control which uses the PIC18F252 and 74LS373 and the `home` trigger circuit which uses an IR emitter and Phototransistor. This standard +5v power regulation circuit makes use of the LM7805 3-pin T2 20 device. A DC filtering capacitor is attached to its output to prevent high frequency spikes from the power supply. The PIC 18F252 uses an 8-bit data bus system with 2 control lines to tell which 74LS373 latch to output data on the bus to turn on/off LEDs.

With this design, we can only send data to one 74LS373 at a time, which just means LED output updates will be nearly simultaneous instead of 100% simultaneous. In order to know when the system should restart displaying the current image on the propeller clock, we need a known reference point called `home`.

An IR emitter diode shines bright into a phototransistor. This turns the transistor `On` connecting the +5v collector pin to the +0v Emitter pin. The PIC 18F252 will see this `falling edge` transition and know right away it`s back at the home location, 360 °. 🔗 External reference

The Pyro Propeller Clock POV (Persistence of Vision) schematic is designed to facilitate a captivating visual display by employing a combination of electronic components that work in unison. The power supply section, based on the LM7805 voltage regulator, ensures a stable +5V output necessary for the operation of the entire circuit. The inclusion of a DC filtering capacitor serves to smooth out any voltage spikes, ensuring the reliability of the power supply under varying load conditions.

The LED output control is a critical aspect of the design, utilizing the PIC18F252 microcontroller, which is programmed to manage the data flow to the LEDs through the 74LS373 latches. The microcontroller's 8-bit data bus allows for efficient communication with the latches, while the two control lines facilitate the selection of which latch is currently active. This method of operation, where only one latch is addressed at a time, is advantageous as it simplifies the control logic and reduces the complexity of the circuit. The result is a nearly simultaneous update of the LED outputs, creating the illusion of a continuous image when the propeller spins.

The 'home' trigger circuit is essential for maintaining the synchronization of the displayed image. The IR emitter diode emits infrared light, which is detected by the phototransistor. When the IR light is interrupted, the phototransistor switches on, creating a transition from high to low voltage at its collector pin. This transition is detected by the PIC18F252, signaling that the propeller has completed a full rotation and returned to the home position. This feedback mechanism is crucial for ensuring the correct timing and alignment of the visual display, enabling the clock to maintain accurate image representation as it spins.

Overall, the Pyro Propeller Clock POV schematic exemplifies a well-thought-out design that integrates power management, data handling, and position sensing to produce a visually striking display. The careful selection of components and their arrangement within the circuit contribute to the effectiveness and reliability of the final product.The Pyro Propeller Clock POV schematic is actually not very difficult. There are three main parts: the power supply which uses a 7805, the LED output control which uses the PIC18F252 and 74LS373 and the `home` trigger circuit which uses an IR emitter and Phototransistor. This standard +5v power regulation circuit makes use of the LM7805 3-pin T2 20 device. A DC filtering capacitor is attached to its output to prevent high frequency spikes from the power supply. The PIC 18F252 uses an 8-bit data bus system with 2 control lines to tell which 74LS373 latch to output data on the bus to turn on/off LEDs.

With this design, we can only send data to one 74LS373 at a time, which just means LED output updates will be nearly simultaneous instead of 100% simultaneous. In order to know when the system should restart displaying the current image on the propeller clock, we need a known reference point called `home`.

An IR emitter diode shines bright into a phototransistor. This turns the transistor `On` connecting the +5v collector pin to the +0v Emitter pin. The PIC 18F252 will see this `falling edge` transition and know right away it`s back at the home location, 360 °. 🔗 External reference