Rectifier/filter circuit Semiconductors

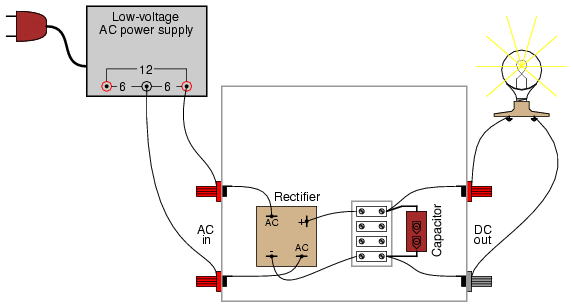

A bridge rectifier module is strongly recommended over building a bridge rectifier circuit using individual diodes. These modules are designed to be mounted on a metal heat sink. A metal enclosure is preferred over a plastic one due to its capability to serve as a heat sink for the rectifier. It is acceptable to use a larger capacitor value in this experiment, provided that its working voltage is sufficiently high. For safety, select a capacitor with a working voltage rating at least twice the RMS AC voltage output of the low-voltage AC power supply. High-wattage 12-volt lamps can be sourced from recreational vehicle (RV) and boating supply stores, with common sizes being 25 watts and 50 watts. These lamps will serve as a substantial load for the power supply. The experiment involves creating a rectifier and filter circuit to connect to the previously constructed low-voltage AC power supply. This device will provide a source of low-voltage DC power, which can be used as a substitute for a battery in battery-operated experiments. To create a self-contained 120VAC/DC power supply, all components of the low-voltage AC supply, including a transformer, power cord, and plug, can be added to the "AC in" side of this circuit. Regardless of whether this is done, it is advisable to use a metal box that is larger than necessary, allowing room for any additional voltage regulation circuitry that may be incorporated later. The bridge rectifier unit should be rated for a current that meets or exceeds the rating of the transformer's secondary winding and for a voltage rating at least twice the RMS voltage of the transformer’s output, providing a safety margin for peak voltage. The Radio Shack rectifier specified in the parts list is rated for 25 amps and 50 volts, which is more than adequate for the output of the low-voltage AC power supply described in the AC experiments chapter. Such rectifier units often come equipped with "quick-disconnect" terminals. Complementary "quick-disconnect" lugs are available that can be crimped onto the bare ends of wires, which is the preferred method for terminal connections. While it is possible to solder wires directly to the rectifier lugs, this is generally discouraged due to the risks of heat damage during soldering and the potential difficulty in replacing components in the event of failure. Semiconductor devices are more susceptible to failure than most components discussed in previous experiments, so if there is any intention of making a circuit permanent, it should be designed for maintainability. This involves ensuring that delicate components are replaceable and that "test points" are accessible for meter probes throughout the circuit, facilitating troubleshooting with minimal inconvenience. Terminal strips naturally provide test points for voltage measurements and allow for easy disconnection of wires without compromising connection durability. The rectifier unit should be bolted to the inside of the metal enclosure, which will act as a radiator to keep the rectifier unit cool under high current conditions. Any metal surface designed to dissipate heat from electronic components is referred to as a heat sink. Semiconductor devices are particularly vulnerable to damage from overheating, making effective heat transfer from the device to the surrounding air critical, especially for circuits handling significant power levels. A capacitor is included in the circuit to function as a filter, reducing ripple voltage. It is essential to connect the capacitor correctly across the DC output terminals of the rectifier, ensuring that the polarities align, as electrolytic capacitors are sensitive to damage from polarity reversal. In this circuit, the internal resistance of the transformer and rectifier must also be taken into account.

The bridge rectifier serves as a crucial component in converting alternating current (AC) to direct current (DC). This conversion is essential for powering various electronic devices and circuits that require a stable DC voltage. The design of the rectifier circuit typically involves four diodes arranged in a bridge configuration, allowing for full-wave rectification. The inclusion of a filter capacitor smooths out the pulsating DC output, ensuring a more stable voltage level for downstream applications.

When selecting components for the bridge rectifier, it is essential to consider the maximum load current and voltage ratings. The rectifier's specifications should match or exceed the expected operational parameters to ensure reliability and prevent component failure. Additionally, proper heat dissipation strategies, such as using a metal enclosure and ensuring adequate airflow, should be implemented to maintain optimal operating temperatures.

In summary, the construction of a bridge rectifier circuit with a metal enclosure and appropriate component selection is vital for achieving an efficient and reliable power supply solution. This setup not only enhances performance but also ensures the longevity and maintainability of the circuit.A bridge rectifier "pack" is highly recommended over constructing a bridge rectifier circuit from individual diodes, because such "packs" are made to bolt onto a metal heat sink. A metal box is recommended over a plastic box for its ability to function as a heat sink for the rectifier.

A larger capacitor value is fine to use in this experiment, so long as its working voltage is high enough. To be safe, choose a capacitor with a working voltage rating at least twice the RMS AC voltage output of the low-voltage AC power supply. High-wattage 12-volt lamps may be purchased from recreational vehicle (RV) and boating supply stores.

Common sizes are 25 watt and 50 watt. This lamp will be used as a "heavy" load for the power supply. This experiment involves constructing a rectifier and filter circuit for attachment to the low-voltage AC power supply constructed earlier. With this device, you will have a source of low-voltage, DC power suitable as a replacement for a battery in battery-powered experiments.

If you would like to make this device its own, self-contained 120VAC/DC power supply, you may add all the componentry of the low-voltage AC supply to the "AC in" side of this circuit: a transformer, power cord, and plug. Even if you don`t choose to do this, I recommend using a metal box larger than necessary to provide room for additional voltage regulation circuitry you might choose to add to this project later.

The bridge rectifier unit should be rated for a current at least as high as the transformer`s secondary winding is rated for, and for a voltage at least twice as high as the RMS voltage of the transformer`s output (this allows for peak voltage, plus an additional safety margin). The Radio Shack rectifier specified in the parts list is rated for 25 amps and 50 volts, more than enough for the output of the low-voltage AC power supply specified in the AC experiments chapter.

Rectifier units of this size are often equipped with "quick-disconnect" terminals. Complementary "quick-disconnect" lugs are sold that crimp onto the bare ends of wire. This is the preferred method of terminal connection. You may solder wires directly to the lugs of the rectifier, but I recommend against direct soldering to any semiconductor component for two reasons: possible heat damage during soldering, and difficulty of replacing the component in the event of failure. Semiconductor devices are more prone to failure than most of the components covered in these experiments thus far, and so if you have any intent of making a circuit permanent, you should build it to be maintained.

"Maintainable construction" involves, among other things, making all delicate components replaceable. It also means making "test points" accessible to meter probes throughout the circuit, so that troubleshooting may be executed with a minimum of inconvenience.

Terminal strips inherently provide test points for taking voltage measurements, and they also allow for easy disconnection of wires without sacrificing connection durability. Bolt the rectifier unit to the inside of the metal box. The box`s surface area will act as a radiator, keeping the rectifier unit cool as it passes high currents.

Any metal radiator surface designed to lower the operating temperature of an electronic component is called a heat sink. Semiconductor devices in general are prone to damage from overheating, so providing a path for heat transfer from the device(s) to the ambient air is very important when the circuit in question may handle large amounts of power.

A capacitor is included in the circuit to act as a filter to reduce ripple voltage. Make sure that you connect the capacitor properly across the DC output terminals of the rectifier, so that the polarities match. Being an electrolytic capacitor, it is sensitive to damage by polarity reversal. In this circuit especially, where the internal resistance of the transformer and rectifier are 🔗 External reference

The bridge rectifier serves as a crucial component in converting alternating current (AC) to direct current (DC). This conversion is essential for powering various electronic devices and circuits that require a stable DC voltage. The design of the rectifier circuit typically involves four diodes arranged in a bridge configuration, allowing for full-wave rectification. The inclusion of a filter capacitor smooths out the pulsating DC output, ensuring a more stable voltage level for downstream applications.

When selecting components for the bridge rectifier, it is essential to consider the maximum load current and voltage ratings. The rectifier's specifications should match or exceed the expected operational parameters to ensure reliability and prevent component failure. Additionally, proper heat dissipation strategies, such as using a metal enclosure and ensuring adequate airflow, should be implemented to maintain optimal operating temperatures.

In summary, the construction of a bridge rectifier circuit with a metal enclosure and appropriate component selection is vital for achieving an efficient and reliable power supply solution. This setup not only enhances performance but also ensures the longevity and maintainability of the circuit.A bridge rectifier "pack" is highly recommended over constructing a bridge rectifier circuit from individual diodes, because such "packs" are made to bolt onto a metal heat sink. A metal box is recommended over a plastic box for its ability to function as a heat sink for the rectifier.

A larger capacitor value is fine to use in this experiment, so long as its working voltage is high enough. To be safe, choose a capacitor with a working voltage rating at least twice the RMS AC voltage output of the low-voltage AC power supply. High-wattage 12-volt lamps may be purchased from recreational vehicle (RV) and boating supply stores.

Common sizes are 25 watt and 50 watt. This lamp will be used as a "heavy" load for the power supply. This experiment involves constructing a rectifier and filter circuit for attachment to the low-voltage AC power supply constructed earlier. With this device, you will have a source of low-voltage, DC power suitable as a replacement for a battery in battery-powered experiments.

If you would like to make this device its own, self-contained 120VAC/DC power supply, you may add all the componentry of the low-voltage AC supply to the "AC in" side of this circuit: a transformer, power cord, and plug. Even if you don`t choose to do this, I recommend using a metal box larger than necessary to provide room for additional voltage regulation circuitry you might choose to add to this project later.

The bridge rectifier unit should be rated for a current at least as high as the transformer`s secondary winding is rated for, and for a voltage at least twice as high as the RMS voltage of the transformer`s output (this allows for peak voltage, plus an additional safety margin). The Radio Shack rectifier specified in the parts list is rated for 25 amps and 50 volts, more than enough for the output of the low-voltage AC power supply specified in the AC experiments chapter.

Rectifier units of this size are often equipped with "quick-disconnect" terminals. Complementary "quick-disconnect" lugs are sold that crimp onto the bare ends of wire. This is the preferred method of terminal connection. You may solder wires directly to the lugs of the rectifier, but I recommend against direct soldering to any semiconductor component for two reasons: possible heat damage during soldering, and difficulty of replacing the component in the event of failure. Semiconductor devices are more prone to failure than most of the components covered in these experiments thus far, and so if you have any intent of making a circuit permanent, you should build it to be maintained.

"Maintainable construction" involves, among other things, making all delicate components replaceable. It also means making "test points" accessible to meter probes throughout the circuit, so that troubleshooting may be executed with a minimum of inconvenience.

Terminal strips inherently provide test points for taking voltage measurements, and they also allow for easy disconnection of wires without sacrificing connection durability. Bolt the rectifier unit to the inside of the metal box. The box`s surface area will act as a radiator, keeping the rectifier unit cool as it passes high currents.

Any metal radiator surface designed to lower the operating temperature of an electronic component is called a heat sink. Semiconductor devices in general are prone to damage from overheating, so providing a path for heat transfer from the device(s) to the ambient air is very important when the circuit in question may handle large amounts of power.

A capacitor is included in the circuit to act as a filter to reduce ripple voltage. Make sure that you connect the capacitor properly across the DC output terminals of the rectifier, so that the polarities match. Being an electrolytic capacitor, it is sensitive to damage by polarity reversal. In this circuit especially, where the internal resistance of the transformer and rectifier are 🔗 External reference