Regulated Positive Voltage Booster

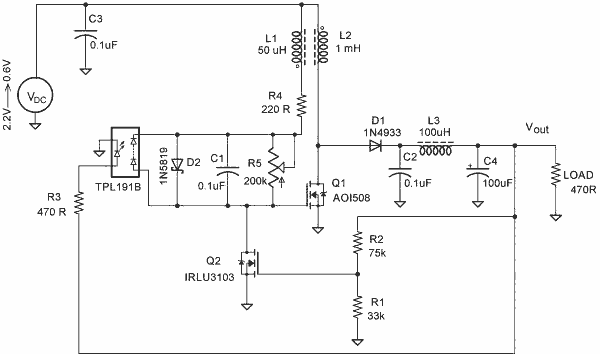

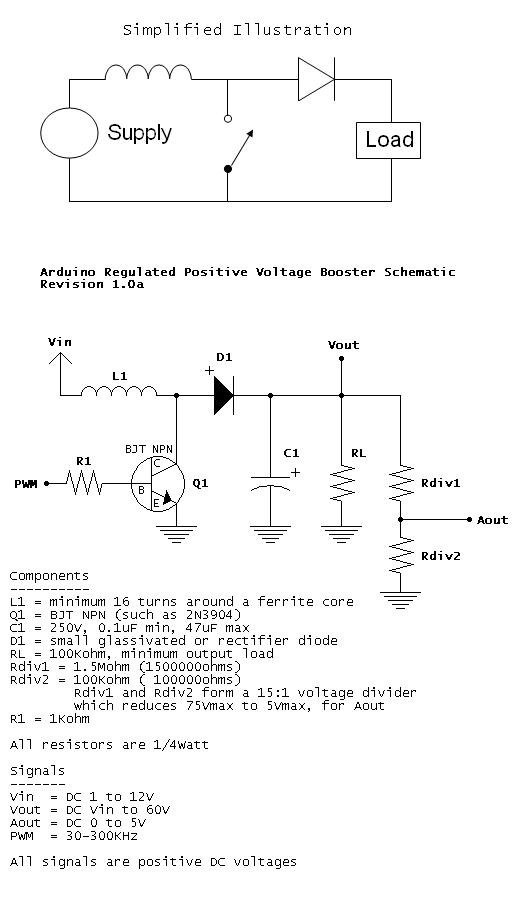

When Q1 is active, a larger current begins to flow through L1 to ground. When Q1 is switched off, the current through L1 tries to remain constant, resulting in an increased voltage. By varying the PWM duty cycle, the current through L1 and the output voltage can be controlled. The relationship between PWM (analog output) and output voltage can be simply described: as the PWM duty cycle increases, the voltage also increases, provided the output load remains constant. PWM controls power; if the output current remains constant, the voltage increases according to the formula P=VI. Conversely, for any given PWM, if the output current is reduced, the voltage will increase. Without regulation, the output voltage would vary with changes in load. The gain of the transistor is not a concern; correct connection is essential. When powered by batteries or an Arduino, the transistor's gain has minimal impact on output power. Although the transistor is rated for 30V DC in most cases, it can safely operate up to 60V for two reasons: 5V logic on the transistor base does not saturate it, leading to a voltage drop across the transistor that is generally less than half the circuit's output voltage; and when the transistor is off and not conducting, the voltage rises, dropping back closer to the input voltage when the transistor is turned on again. This allows most 30V NPN transistors to handle generating 60V. The specific inductance of L1 is not critical, as the circuit can utilize almost any inductor. Any insulated wire wrapped at least 16 times around a metal object should suffice, regardless of the wire gauge. The process of creating an inductor does not require an inductance meter; simply wrapping wire around a metal object multiple times is effective. For applications exceeding one watt, a Darlington pair is recommended. With BJT power transistors, the maximum efficient output is about 4 watts, while N-channel power MOSFETs can achieve approximately 25 watts at around 70% efficiency with a suitable power inductor. Exceeding 30 watts may result in efficiency loss, necessitating a different PWM frequency or a more complex switch. The Arduino ATMega168 regulates the output voltage, which is crucial when the output load varies. The software detects changes in output voltage and adjusts the PWM accordingly. The output voltage is influenced by load and input voltage, which are variable factors, leading the program to estimate the mathematical relationship between PWM duty cycle and output voltage. If input voltage and output load were constant, the Arduino's analog input would be unnecessary. Due to regulation, various loads and input voltages can yield an accurate output voltage. Each inductor behaves differently; those with thicker wire may not regulate effectively, and certain barrel-shaped inductors may not exceed 24V. Hand-made inductors may fail due to sharp edges damaging the wire insulation, causing shorts. The screw in one example did not have enough turns. Connect ADC pin 0 to circuit Aout, located between the 1.5M and 100K resistors shown in the schematic. Ensure ADC pin 0 is connected properly; otherwise, output voltage regulation will fail.

The circuit described operates on the principles of PWM control and inductive energy storage, utilizing a transistor switch (Q1) to modulate the current flowing through an inductor (L1). The inductor serves as an energy storage element, allowing for the regulation of output voltage based on the duty cycle of the PWM signal. The transistor operates in a switching mode, where it alternately allows current to flow through the inductor and then interrupts that flow, causing the inductor to release its stored energy and maintain the output voltage.

In this design, it is crucial to select an appropriate inductor, as its inductance value will influence the circuit's response to PWM signals and the efficiency of energy transfer. The inductor must be constructed with insulated wire to prevent short circuits, and its physical dimensions should be adequate to handle the expected current levels without overheating.

The Arduino ATMega168 plays a pivotal role in monitoring and adjusting the output voltage based on feedback from the circuit. By employing an analog-to-digital converter (ADC), the microcontroller can continuously assess the output voltage and modify the PWM duty cycle to maintain a stable output, accommodating variations in load. This feedback loop enhances the circuit's performance and reliability, ensuring that the output voltage remains within desired parameters.

In summary, the design leverages the properties of inductive components and PWM control to achieve efficient voltage regulation, with careful consideration given to component selection, circuit topology, and feedback mechanisms for optimal performance.When Q1 is active, a larger current begins to flow through L1 to GND. When Q1 is switched off, the current through L1 trys to remain the same as it was, causing an increased voltage. By varying the PWM duty cycle, the current through L1 and output voltage can be controlled. There are many ways to explain the relationship between PWM (analog output) and output voltage. The simplest way to put it, is that as PWM duty cycle increases, the voltage also increases. This is true when the output load remains constant. What the PWM does is control power, and if output current remains constant, then the voltage increases (P=VI). Alternately, at any given PWM if the output current is reduced, the voltage will increase. Without regulation, the output voltage would change as the load changed. Don`t worry about the gain of the transistor. (I`ve tested 2N3904, 2N2222, 2N4124, etc. ) Connecting it correctly, is all that`s important. When the circuit is powered by batteries or the Arduino, the gain of the transistor will have little effect on ouput power.

Also note that even though the transistor is rated for 30Vdc (in most cases), it should be safe to use up to 60Vdc for two reasons. 5V logic on the transistor base doesn`t saturate it, so the voltage drop across the transistor is generally less than 1/2 the circuit output voltage.

The second reason is that the voltage rises when the transistor is off and not conducting. By the time the transistor is turned back on, the voltage should have dropped back down closer to the input voltage. This is why most 30V NPNs can handle generating 60V. The exact inductance of L1 doesn`t matter. The circuit is capable of using almost any inductor. Any insulated wire wrapped at least 16 times around metal should work, regardless of the wire`s guage (thickness).

I don`t even own an inductance meter, and this is the first time I`ve used inductors in a project. I randomly wrapped wire around metal, and had a working inductor on my third try. It`s easy, my advice is don`t let it intimidate you. Just remember the important parts: insulated wire (not bare wire) wrapped tight around a smooth metal object (sharp edges could cut the insulation), and wrap the wire around the metal more than a dozen times. Take a look at the pictures below, try making your first inductor about the same size as them. If you`re trying to get more than one watt, then use a darlington pair. With BJT power transistors, the most you`ll get is about 4 watts, efficiently. With N-Channel power MOSFETs, it`s possible to get 25 watts at about 70% efficiency with a good power inductor (it`s very difficult).

To get past 30 watts, you`ll lose efficiency, need a different frequency PWM, or an elaborate/expensive switch. The Arduino ATMega168 regulates the output voltage. Regulation is important when the output load varys. The software senses changes in the output voltage, and adjusts the PWM to compensate. The output voltage depends on load and input voltage, which are "unknown" variables, so the mathematical relationship between PWM duty cycle and output voltage are "guessed" by the program.

If the input voltage and output load were constant, the Arduino analog input wouldn`t be necessary. Because of regulation, almost any load and input voltage can be used to make an accurate output voltage. Each inductor behaved a bit differently. The ones with thick wire didn`t regulate well, and the barrel/can shaped inductors in the top row generally wouldn`t go above 24V.

The top two inductors were hand made, but didn`t work. The washer had sharp edges that probably scratched enamel off the wire, shorting it. The screw just doesn`t have enough turns. Connect ADC pin 0 to circuit Aout, which is between the 1. 5M and 100K resistors shown in the schematic. Make sure ADC pin 0 is connected correctly, or your output voltage wont be regulated. 🔗 External reference

The circuit described operates on the principles of PWM control and inductive energy storage, utilizing a transistor switch (Q1) to modulate the current flowing through an inductor (L1). The inductor serves as an energy storage element, allowing for the regulation of output voltage based on the duty cycle of the PWM signal. The transistor operates in a switching mode, where it alternately allows current to flow through the inductor and then interrupts that flow, causing the inductor to release its stored energy and maintain the output voltage.

In this design, it is crucial to select an appropriate inductor, as its inductance value will influence the circuit's response to PWM signals and the efficiency of energy transfer. The inductor must be constructed with insulated wire to prevent short circuits, and its physical dimensions should be adequate to handle the expected current levels without overheating.

The Arduino ATMega168 plays a pivotal role in monitoring and adjusting the output voltage based on feedback from the circuit. By employing an analog-to-digital converter (ADC), the microcontroller can continuously assess the output voltage and modify the PWM duty cycle to maintain a stable output, accommodating variations in load. This feedback loop enhances the circuit's performance and reliability, ensuring that the output voltage remains within desired parameters.

In summary, the design leverages the properties of inductive components and PWM control to achieve efficient voltage regulation, with careful consideration given to component selection, circuit topology, and feedback mechanisms for optimal performance.When Q1 is active, a larger current begins to flow through L1 to GND. When Q1 is switched off, the current through L1 trys to remain the same as it was, causing an increased voltage. By varying the PWM duty cycle, the current through L1 and output voltage can be controlled. There are many ways to explain the relationship between PWM (analog output) and output voltage. The simplest way to put it, is that as PWM duty cycle increases, the voltage also increases. This is true when the output load remains constant. What the PWM does is control power, and if output current remains constant, then the voltage increases (P=VI). Alternately, at any given PWM if the output current is reduced, the voltage will increase. Without regulation, the output voltage would change as the load changed. Don`t worry about the gain of the transistor. (I`ve tested 2N3904, 2N2222, 2N4124, etc. ) Connecting it correctly, is all that`s important. When the circuit is powered by batteries or the Arduino, the gain of the transistor will have little effect on ouput power.

Also note that even though the transistor is rated for 30Vdc (in most cases), it should be safe to use up to 60Vdc for two reasons. 5V logic on the transistor base doesn`t saturate it, so the voltage drop across the transistor is generally less than 1/2 the circuit output voltage.

The second reason is that the voltage rises when the transistor is off and not conducting. By the time the transistor is turned back on, the voltage should have dropped back down closer to the input voltage. This is why most 30V NPNs can handle generating 60V. The exact inductance of L1 doesn`t matter. The circuit is capable of using almost any inductor. Any insulated wire wrapped at least 16 times around metal should work, regardless of the wire`s guage (thickness).

I don`t even own an inductance meter, and this is the first time I`ve used inductors in a project. I randomly wrapped wire around metal, and had a working inductor on my third try. It`s easy, my advice is don`t let it intimidate you. Just remember the important parts: insulated wire (not bare wire) wrapped tight around a smooth metal object (sharp edges could cut the insulation), and wrap the wire around the metal more than a dozen times. Take a look at the pictures below, try making your first inductor about the same size as them. If you`re trying to get more than one watt, then use a darlington pair. With BJT power transistors, the most you`ll get is about 4 watts, efficiently. With N-Channel power MOSFETs, it`s possible to get 25 watts at about 70% efficiency with a good power inductor (it`s very difficult).

To get past 30 watts, you`ll lose efficiency, need a different frequency PWM, or an elaborate/expensive switch. The Arduino ATMega168 regulates the output voltage. Regulation is important when the output load varys. The software senses changes in the output voltage, and adjusts the PWM to compensate. The output voltage depends on load and input voltage, which are "unknown" variables, so the mathematical relationship between PWM duty cycle and output voltage are "guessed" by the program.

If the input voltage and output load were constant, the Arduino analog input wouldn`t be necessary. Because of regulation, almost any load and input voltage can be used to make an accurate output voltage. Each inductor behaved a bit differently. The ones with thick wire didn`t regulate well, and the barrel/can shaped inductors in the top row generally wouldn`t go above 24V.

The top two inductors were hand made, but didn`t work. The washer had sharp edges that probably scratched enamel off the wire, shorting it. The screw just doesn`t have enough turns. Connect ADC pin 0 to circuit Aout, which is between the 1. 5M and 100K resistors shown in the schematic. Make sure ADC pin 0 is connected correctly, or your output voltage wont be regulated. 🔗 External reference