Rotative Speed Regulator Borer Driller Controller

This rotary speed regulator circuit schematic enables control over the rotational speed of a borer or drilling machine. This project is based on the principle that...

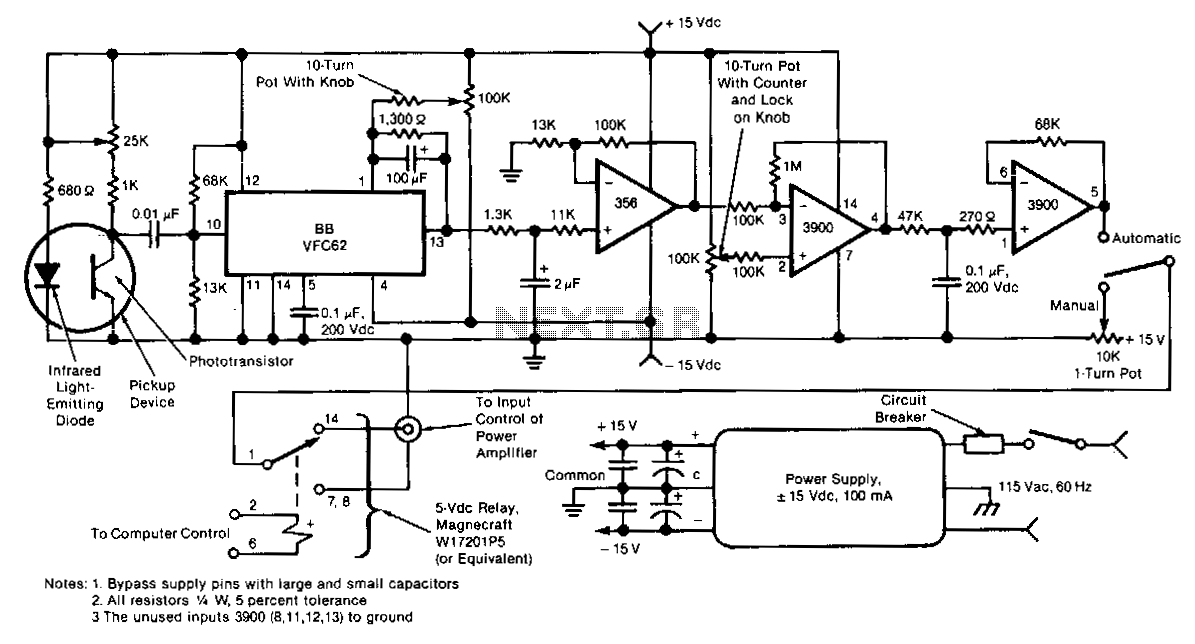

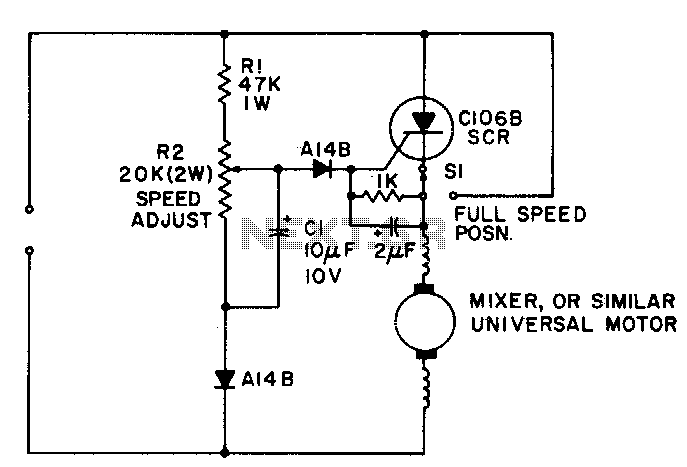

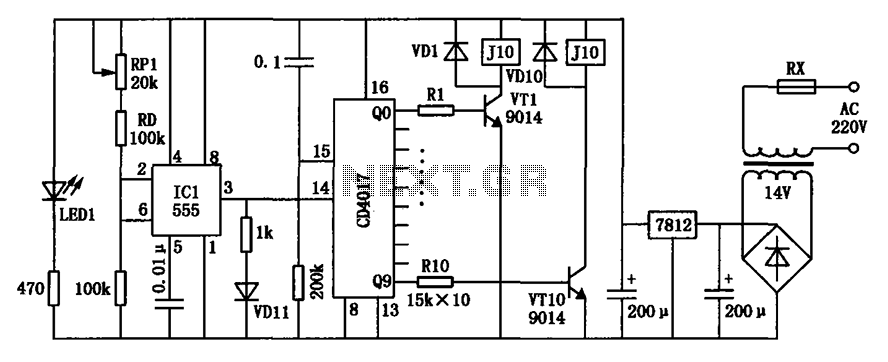

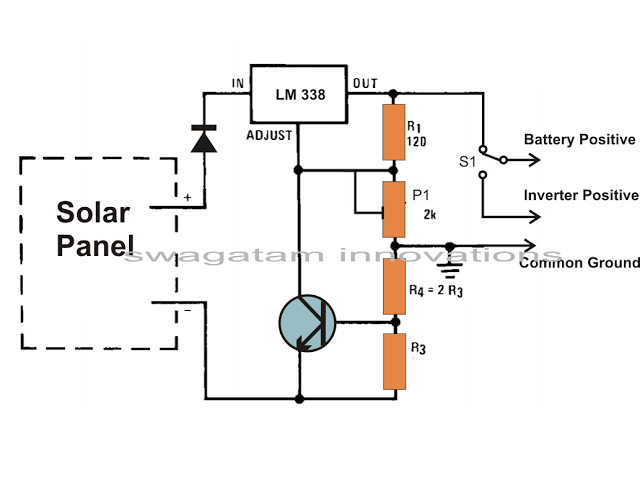

The rotary speed regulator circuit is designed to modulate the speed of electric motors commonly used in drilling and boring applications. The key components typically include a variable resistor, a transistor, and a microcontroller or a dedicated speed control IC, which collectively manage the voltage and current supplied to the motor.

In this circuit, the variable resistor allows the user to adjust the resistance, which in turn alters the voltage drop across the motor. This adjustment leads to a change in the speed of the motor's rotation. The transistor acts as a switch that can handle high current loads while being controlled by a low voltage signal from the microcontroller or speed control IC.

The microcontroller can be programmed to provide precise control over the motor speed, enabling features such as ramp-up and ramp-down speeds to prevent mechanical stress during operation. Feedback mechanisms, such as tachometers or encoders, may be integrated into the circuit to provide real-time speed monitoring and adjustments, ensuring optimal performance under varying load conditions.

Safety features, such as overcurrent protection and thermal shutdown, can also be incorporated to protect the circuit and the motor from damage during prolonged use or under heavy load conditions. The layout of the circuit should be designed to minimize noise and interference, ensuring stable operation and accurate speed regulation.

Overall, this rotary speed regulator circuit schematic represents an essential tool for enhancing the functionality and efficiency of drilling machines, providing users with the ability to tailor motor speed to specific applications and material requirements.This rotative speed regulator circuit schematic allows to control the holing speed of your borer or driller machine. This project is based on the fact tha.. 🔗 External reference

The rotary speed regulator circuit is designed to modulate the speed of electric motors commonly used in drilling and boring applications. The key components typically include a variable resistor, a transistor, and a microcontroller or a dedicated speed control IC, which collectively manage the voltage and current supplied to the motor.

In this circuit, the variable resistor allows the user to adjust the resistance, which in turn alters the voltage drop across the motor. This adjustment leads to a change in the speed of the motor's rotation. The transistor acts as a switch that can handle high current loads while being controlled by a low voltage signal from the microcontroller or speed control IC.

The microcontroller can be programmed to provide precise control over the motor speed, enabling features such as ramp-up and ramp-down speeds to prevent mechanical stress during operation. Feedback mechanisms, such as tachometers or encoders, may be integrated into the circuit to provide real-time speed monitoring and adjustments, ensuring optimal performance under varying load conditions.

Safety features, such as overcurrent protection and thermal shutdown, can also be incorporated to protect the circuit and the motor from damage during prolonged use or under heavy load conditions. The layout of the circuit should be designed to minimize noise and interference, ensuring stable operation and accurate speed regulation.

Overall, this rotary speed regulator circuit schematic represents an essential tool for enhancing the functionality and efficiency of drilling machines, providing users with the ability to tailor motor speed to specific applications and material requirements.This rotative speed regulator circuit schematic allows to control the holing speed of your borer or driller machine. This project is based on the fact tha.. 🔗 External reference