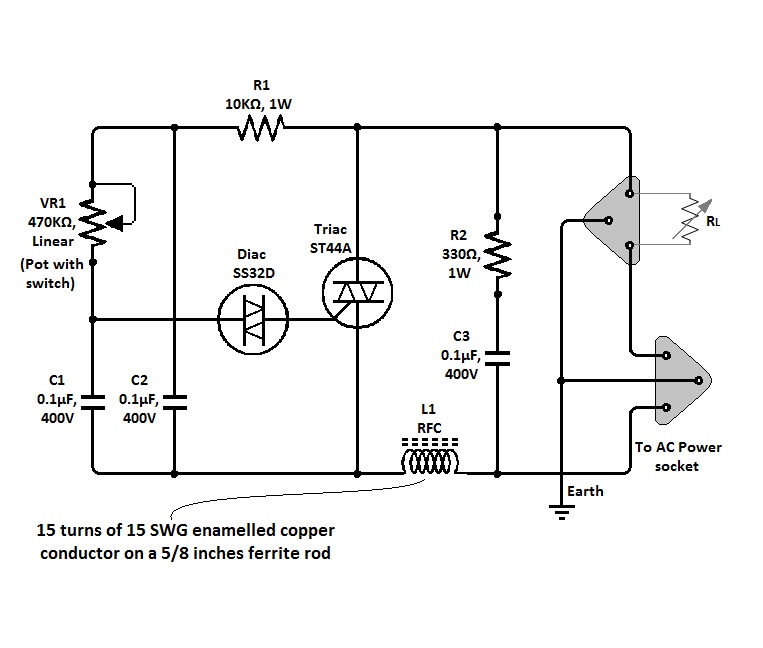

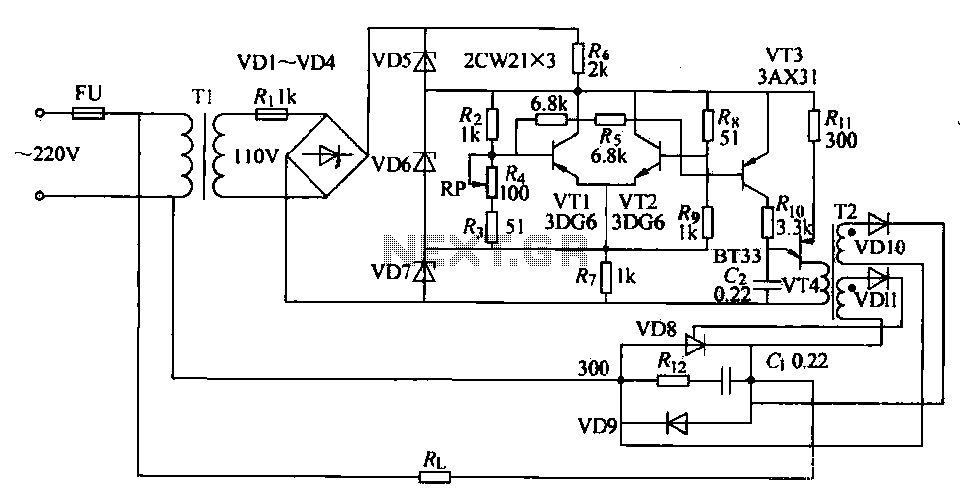

SCR furnace temperature regulating circuit

The circuit consists of two differential amplifier transistors configured with a voltage dividing type bias circuit, measuring the resistance of four arms in a bridge configuration. The product includes a platinum resistance sensor, which exhibits an increase in resistance with rising temperature and a decrease in resistance with falling temperature. This setup is utilized for temperature measurement in electric furnaces. Adjusting the resistance of the potentiometer RP allows for setting a desired furnace temperature. If the measured temperature is lower than the set temperature, the resistance R4 decreases, causing the bridge to become unbalanced. This results in a potential drop across the transistor VT2, leading to a decrease in collector current. As the collector current flows through the emitter resistor (lk), the emitter potential of the two transistors declines, which in turn increases the collector current of VT1. The collector potential drop influences the base potential of the charging circuit transistor 3AX31B, resulting in an increase in charging current, which advances the trigger pulse and increases the conduction angle of the thyristor, thereby raising the furnace temperature. Conversely, when the temperature is high, the opposite effects occur. Thus, the differential amplifier effectively achieves automatic temperature regulation for the furnace.

The described circuit utilizes a differential amplifier configuration to monitor and regulate the temperature of an electric furnace. The two transistors in the differential amplifier are biased through a voltage divider arrangement, ensuring stable operation across varying temperatures. The platinum resistance sensor serves as the primary temperature sensing element, characterized by its predictable resistance change in response to temperature fluctuations.

In the bridge circuit, the four arms are balanced under normal operating conditions, with the platinum sensor providing a variable resistance that alters the balance as temperature changes. The potentiometer RP allows for user-defined temperature settings, enabling precise control over the furnace's operating conditions.

As the furnace temperature deviates from the set point, the circuit responds dynamically. A decrease in the measured temperature leads to a reduction in R4, disrupting the balance of the bridge. This unbalance generates a differential voltage that affects the base-emitter junctions of the transistors. The resulting changes in collector currents through the emitter resistors lead to a cascading effect that ultimately adjusts the firing angle of the thyristor, thereby modulating the power delivered to the heating element.

The integration of the 3AX31B transistor within the charging circuit is crucial for enhancing the response time of the system. By controlling the charging current, the circuit ensures rapid adjustments to the thyristor's conduction angle, facilitating swift temperature increases when necessary. This feedback mechanism is essential for maintaining the desired operating temperature and preventing overheating.

Overall, the described electronic schematic provides a sophisticated solution for automatic temperature control in electric furnaces, leveraging the properties of differential amplifiers and the thermal characteristics of platinum resistance sensors.Consisting of two differential amplifier transistors voltage dividing type bias circuit, and this resistance is measured four bridge four of arm. Wherein the product is a plati num resistance, its resistance increases with increasing temperature, and decreases with decreasing temperature, it is to release electric furnace temperature measurement devices. Change the resistance of the potentiometer RP can be given a furnace. When compared with a given oven temperature is low. R4 resistance decreases, the bridge out of balance. VT2 group Xi potential drop, the collector current decreases. As the two tube collector current flows through the emitter resistor (lk), so that the emitter potential of the two tubes of decline, VT1 collector current increases, the collector potential drop in the charging circuit transistor 3AX31B base potential drop, the charging current increases, the trigger pulse in advance, the thyristor conduction angle increases, the furnace temperature rises.

When the temperature is high, everything changes on said opposite. Therefore, the differential amplifier can be used to achieve the purpose of automatically adjusting the furnace temperature.

The described circuit utilizes a differential amplifier configuration to monitor and regulate the temperature of an electric furnace. The two transistors in the differential amplifier are biased through a voltage divider arrangement, ensuring stable operation across varying temperatures. The platinum resistance sensor serves as the primary temperature sensing element, characterized by its predictable resistance change in response to temperature fluctuations.

In the bridge circuit, the four arms are balanced under normal operating conditions, with the platinum sensor providing a variable resistance that alters the balance as temperature changes. The potentiometer RP allows for user-defined temperature settings, enabling precise control over the furnace's operating conditions.

As the furnace temperature deviates from the set point, the circuit responds dynamically. A decrease in the measured temperature leads to a reduction in R4, disrupting the balance of the bridge. This unbalance generates a differential voltage that affects the base-emitter junctions of the transistors. The resulting changes in collector currents through the emitter resistors lead to a cascading effect that ultimately adjusts the firing angle of the thyristor, thereby modulating the power delivered to the heating element.

The integration of the 3AX31B transistor within the charging circuit is crucial for enhancing the response time of the system. By controlling the charging current, the circuit ensures rapid adjustments to the thyristor's conduction angle, facilitating swift temperature increases when necessary. This feedback mechanism is essential for maintaining the desired operating temperature and preventing overheating.

Overall, the described electronic schematic provides a sophisticated solution for automatic temperature control in electric furnaces, leveraging the properties of differential amplifiers and the thermal characteristics of platinum resistance sensors.Consisting of two differential amplifier transistors voltage dividing type bias circuit, and this resistance is measured four bridge four of arm. Wherein the product is a plati num resistance, its resistance increases with increasing temperature, and decreases with decreasing temperature, it is to release electric furnace temperature measurement devices. Change the resistance of the potentiometer RP can be given a furnace. When compared with a given oven temperature is low. R4 resistance decreases, the bridge out of balance. VT2 group Xi potential drop, the collector current decreases. As the two tube collector current flows through the emitter resistor (lk), so that the emitter potential of the two tubes of decline, VT1 collector current increases, the collector potential drop in the charging circuit transistor 3AX31B base potential drop, the charging current increases, the trigger pulse in advance, the thyristor conduction angle increases, the furnace temperature rises.

When the temperature is high, everything changes on said opposite. Therefore, the differential amplifier can be used to achieve the purpose of automatically adjusting the furnace temperature.