Simple Infrared Remote Control Extender

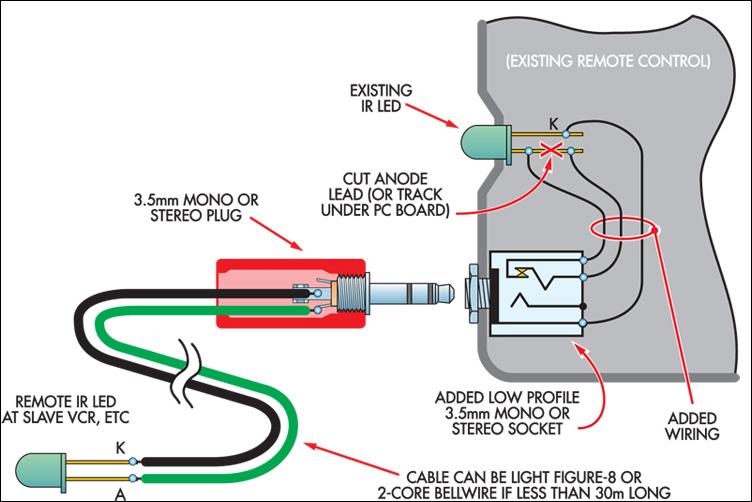

This ultra-simple remote control extender is ideal for use with a hidden video recorder. The recorder is a Panasonic NV-SD200 and is employed as part of a camera surveillance system. A PICAXE-08-based circuit detects events and controls the recorder. Additionally, it flashes an LED near the monitor to indicate the number of events since the last viewing. Interestingly, the NV-SD200 model was incompatible with several commercial infrared remote control extenders, which necessitated this design. Furthermore, it consumes less power than traditional extenders (no plug packs) while allowing the remote to be used in the usual manner. An additional 5mm infrared LED is mounted directly in front of the equipment to be controlled. This LED is connected back to a convenient location near the monitor and terminated with a 3.5mm plug. To modify the remote control unit, the circuit to the anode of the existing infrared LED must be interrupted and wired to a 3.5mm headphone socket. In most instances, the LED will be accessible without dismantling the circuit board. The purpose of the socket is to enable the existing infrared LED to function normally when the jack is unplugged. If the socket cannot fit inside the case, a very short flying lead with a molded in-line socket can be utilized instead. By employing light-duty figure-eight cable, the transmitting LED can be positioned 30 meters or more from the handheld remote control without issues.

The described remote control extender employs a PICAXE-08 microcontroller, which is a versatile and compact device suitable for handling low-power tasks. The circuit is designed to interface with the Panasonic NV-SD200 video recorder, which is part of a surveillance setup. The functionality of the system revolves around event detection and control signaling, which is achieved through the microcontroller's programming.

The LED indicator serves a dual purpose: it not only provides visual feedback regarding the number of events detected but also acts as a status light for the user. This feature enhances user interaction, allowing for immediate awareness of system activity. The design incorporates an additional 5mm infrared LED strategically placed to ensure optimal line-of-sight communication with the recorder. This LED is connected via light-duty figure-eight cable, which is both flexible and capable of extending the distance between the remote control and the recorder up to 30 meters, thus offering significant versatility in installation.

To modify the existing remote control, a careful interruption of the circuit to the anode of the current infrared LED is necessary. This modification allows for the integration of a 3.5mm headphone socket, which facilitates the connection of the new LED while maintaining the functionality of the original remote. The design consideration of allowing the original LED to operate normally when the jack is unplugged ensures that users can revert to the standard operation without any hassle.

In cases where space constraints exist within the remote control casing, the use of a short flying lead with a molded in-line socket provides a practical solution, ensuring that the design remains compact and functional. Overall, this remote control extender design is an efficient and effective solution for extending the range of infrared control for the Panasonic NV-SD200, while also being conscious of power consumption and user convenience.This ultra-simple remote control extender is ideal for use with a hidden video recorder. The recorder is a Panasonic NV-SD200 and is used as part of a camera surveillance system. A PICAXE-08-based circuit is used to detect events and control the recorder. It also flashes a LED near the monitor to indicate the number of events since last viewing. S trangely, the NV-SD200 model refused to work with a number of commercial infrared remote control extenders, hence the need for this design. As a bonus, it uses less power than a traditional extender (no plugpacks) and the remote can still be used in the normal manner.

As shown, an additional 5mm infrared LED is mounted directly in front of the equipment to be controlled. This is cabled back to a convenient location near the monitor and terminated in a 3. 5mm plug. To modify the remote control unit, break the circuit to the anode of the existing infrared LED and wire in a 3.

5mm headphone socket. In most cases, the LED will be accessible without dismantling the circuit board. The purpose of the socket is to allow the existing infrared LED to operate normally when the jack is unplugged. If the socket won`t fit inside the case, then a very short flying lead with a moulded in-line socket can be used instead.

By using light-duty figure-eight cable, the transmitting LED could be 30m or more from the hand-held remote control without problems. 🔗 External reference

The described remote control extender employs a PICAXE-08 microcontroller, which is a versatile and compact device suitable for handling low-power tasks. The circuit is designed to interface with the Panasonic NV-SD200 video recorder, which is part of a surveillance setup. The functionality of the system revolves around event detection and control signaling, which is achieved through the microcontroller's programming.

The LED indicator serves a dual purpose: it not only provides visual feedback regarding the number of events detected but also acts as a status light for the user. This feature enhances user interaction, allowing for immediate awareness of system activity. The design incorporates an additional 5mm infrared LED strategically placed to ensure optimal line-of-sight communication with the recorder. This LED is connected via light-duty figure-eight cable, which is both flexible and capable of extending the distance between the remote control and the recorder up to 30 meters, thus offering significant versatility in installation.

To modify the existing remote control, a careful interruption of the circuit to the anode of the current infrared LED is necessary. This modification allows for the integration of a 3.5mm headphone socket, which facilitates the connection of the new LED while maintaining the functionality of the original remote. The design consideration of allowing the original LED to operate normally when the jack is unplugged ensures that users can revert to the standard operation without any hassle.

In cases where space constraints exist within the remote control casing, the use of a short flying lead with a molded in-line socket provides a practical solution, ensuring that the design remains compact and functional. Overall, this remote control extender design is an efficient and effective solution for extending the range of infrared control for the Panasonic NV-SD200, while also being conscious of power consumption and user convenience.This ultra-simple remote control extender is ideal for use with a hidden video recorder. The recorder is a Panasonic NV-SD200 and is used as part of a camera surveillance system. A PICAXE-08-based circuit is used to detect events and control the recorder. It also flashes a LED near the monitor to indicate the number of events since last viewing. S trangely, the NV-SD200 model refused to work with a number of commercial infrared remote control extenders, hence the need for this design. As a bonus, it uses less power than a traditional extender (no plugpacks) and the remote can still be used in the normal manner.

As shown, an additional 5mm infrared LED is mounted directly in front of the equipment to be controlled. This is cabled back to a convenient location near the monitor and terminated in a 3. 5mm plug. To modify the remote control unit, break the circuit to the anode of the existing infrared LED and wire in a 3.

5mm headphone socket. In most cases, the LED will be accessible without dismantling the circuit board. The purpose of the socket is to allow the existing infrared LED to operate normally when the jack is unplugged. If the socket won`t fit inside the case, then a very short flying lead with a moulded in-line socket can be used instead.

By using light-duty figure-eight cable, the transmitting LED could be 30m or more from the hand-held remote control without problems. 🔗 External reference