Single-phase double-winding motor driving

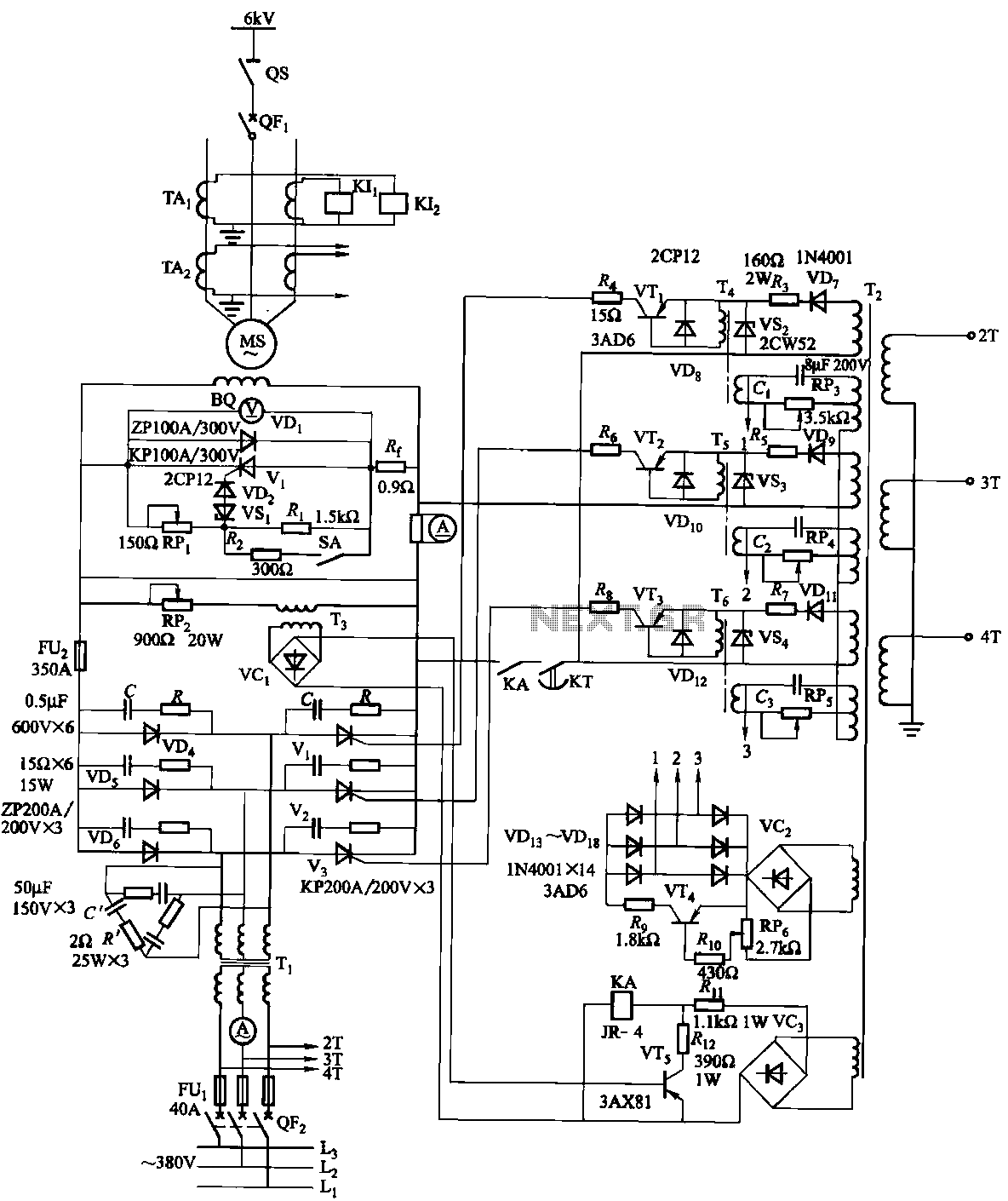

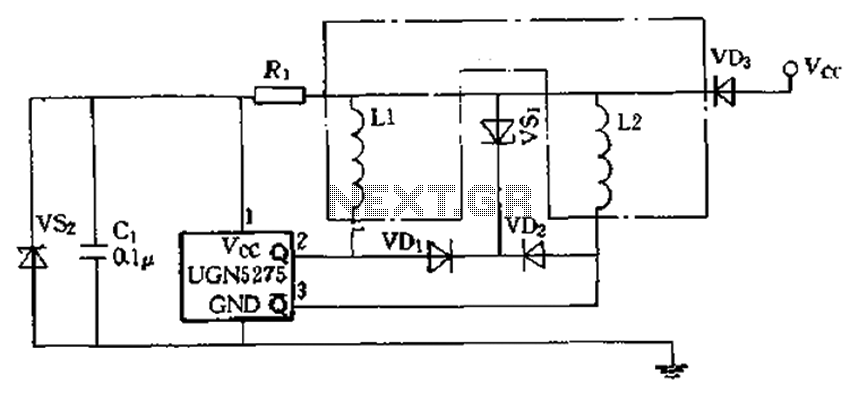

The circuit features almost open collector outputs with a withstand voltage of 60V and a continuous conduction current of 0.3A. The typical voltage drop is 0.4V, with a peak current capability of 9A. It can directly drive two windings and requires minimal external components, making it a low-cost solution. The monolithic design supports a single-phase brushless DC motor with output Q (pin 2) and acupuncture (pin 3) functioning complementarily. When the Hall generator senses that the magnetic flux density exceeds the action value (BOP), output Q transitions to low, followed by acupuncture transitioning to high after a delay. Conversely, when the anti-polarity magnetic induction reaches the BRP value, output Q goes high while acupuncture remains low. The circuit includes an internal temperature compensation mechanism, maintaining a stable switching point within an operating temperature range of -20°C to +80°C. The supply voltage ranges from 5V to 14V, with Bc values between 0.0025T and 0.025T, and BRP values from 0.025T to 0.0025T, while BHYs is 0.01T. An application circuit example includes freewheeling circuits composed of two windings that clamp spikes induced by electromotive force to protect the output transistor. It is important to note that the maximum starting current, determined by the motor's power supply voltage and winding resistance, should not exceed the maximum allowable current rating of the IC.

The circuit operates as a versatile and efficient driver for single-phase brushless DC motors, leveraging an internal Hall effect sensor to monitor the magnetic field. The outputs are designed to provide complementary signals that facilitate the control of motor windings, ensuring smooth operation and efficient energy use. The internal temperature compensation feature is particularly advantageous, allowing the circuit to maintain performance across a wide temperature range, making it suitable for various environmental conditions.

The design minimizes external component requirements, which contributes to a lower overall cost and a more compact system layout. The inclusion of a freewheeling circuit helps to mitigate voltage spikes that can occur during motor operation, protecting the output transistor from potential damage. This aspect is crucial in ensuring the longevity and reliability of the circuit in practical applications.

When implementing this circuit, careful consideration must be given to the maximum starting current, as exceeding the IC's specified limits can lead to malfunction or damage. The relationship between the motor's power supply voltage and winding resistance plays a significant role in determining this starting current, and thus should be calculated accurately to ensure safe operation. Overall, this circuit provides a robust solution for driving brushless DC motors with a focus on reliability, efficiency, and cost-effectiveness.Almost open collector two outputs, open a withstand voltage of 60V, continuous conduction current of 0.3A, voltage drop typical type is 0. 4V, Zhang peak current of 9A. Can dir ectly drive two windings and easily compose minimal external components, low cost, monolithic single-phase brushless DC motor output Q (2 feet) and acupuncture (3 feet) are complementary. Hall generator when the internal sense the magnetic flux density exceeds the action value by BOP, Q goes low, and after about acupuncture ws when delayed transition to high.

Conversely, anti-polarity magnetic induction Back BRP value, Q goes high, and acupuncture is low. Since the circuit with internal temperature compensation circuit, in -20 ~ + 80C within the operating temperature range, can maintain a stable switch point. This circuit supply voltage as 5-14V.T ten z5c when, Bc) p . 0025 ~ 0.025T.BRP eleven .025-0.0025T, BHYs O.OIT. Application Circuit Example in, VD, VD, and S. freewheeling circuit composed of two windings and clamping of spikes induced electromotive force to protect lc output transistor.

when you use this circuit to be noted that, when the motor is started, the maximum starting current (determined by the motor power supply voltage and winding resistance) should not exceed the ICs current most large allowable value.

The circuit operates as a versatile and efficient driver for single-phase brushless DC motors, leveraging an internal Hall effect sensor to monitor the magnetic field. The outputs are designed to provide complementary signals that facilitate the control of motor windings, ensuring smooth operation and efficient energy use. The internal temperature compensation feature is particularly advantageous, allowing the circuit to maintain performance across a wide temperature range, making it suitable for various environmental conditions.

The design minimizes external component requirements, which contributes to a lower overall cost and a more compact system layout. The inclusion of a freewheeling circuit helps to mitigate voltage spikes that can occur during motor operation, protecting the output transistor from potential damage. This aspect is crucial in ensuring the longevity and reliability of the circuit in practical applications.

When implementing this circuit, careful consideration must be given to the maximum starting current, as exceeding the IC's specified limits can lead to malfunction or damage. The relationship between the motor's power supply voltage and winding resistance plays a significant role in determining this starting current, and thus should be calculated accurately to ensure safe operation. Overall, this circuit provides a robust solution for driving brushless DC motors with a focus on reliability, efficiency, and cost-effectiveness.Almost open collector two outputs, open a withstand voltage of 60V, continuous conduction current of 0.3A, voltage drop typical type is 0. 4V, Zhang peak current of 9A. Can dir ectly drive two windings and easily compose minimal external components, low cost, monolithic single-phase brushless DC motor output Q (2 feet) and acupuncture (3 feet) are complementary. Hall generator when the internal sense the magnetic flux density exceeds the action value by BOP, Q goes low, and after about acupuncture ws when delayed transition to high.

Conversely, anti-polarity magnetic induction Back BRP value, Q goes high, and acupuncture is low. Since the circuit with internal temperature compensation circuit, in -20 ~ + 80C within the operating temperature range, can maintain a stable switch point. This circuit supply voltage as 5-14V.T ten z5c when, Bc) p . 0025 ~ 0.025T.BRP eleven .025-0.0025T, BHYs O.OIT. Application Circuit Example in, VD, VD, and S. freewheeling circuit composed of two windings and clamping of spikes induced electromotive force to protect lc output transistor.

when you use this circuit to be noted that, when the motor is started, the maximum starting current (determined by the motor power supply voltage and winding resistance) should not exceed the ICs current most large allowable value.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713