slow down a fuel pump

Warning: Undefined array key "extension" in /var/www/html/nextgr/view-circuit.php on line 477

Deprecated: strtolower(): Passing null to parameter #1 ($string) of type string is deprecated in /var/www/html/nextgr/view-circuit.php on line 477

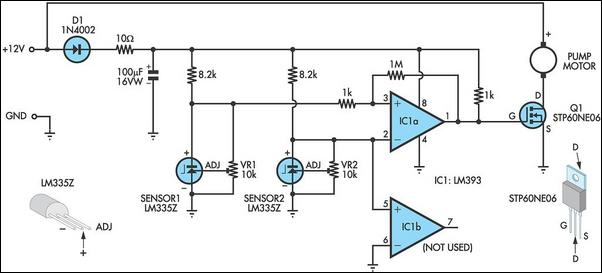

It is possible to enhance fuel pump performance, but can adjustments be made to the wiring of an external pump to reduce fuel flow? This inquiry arises while assisting with an engine swap, specifically installing a 4AGE engine in a KE35 Corolla. The fuel system consists of a lift pump, surge tank, and a 500hp fuel pump. A factory 4AGE fuel pressure regulator is being utilized. A potential solution involves creating a restrictive return line to the tank before the regulator, although this approach may be considered improvised. Alternatively, exchanging the pump with a smaller unit is another option. Regarding the use of resistors, the pump typically draws around 7 to 8 amps at 12 volts and 40 psi, necessitating the use of large wattage resistors, which can be costly. The circuit diagram indicates that the factory resistor relay receives voltage from the circuit opening relay through a light blue/red wire. This wire splits into two sections. When the resistor relay is off (coil disengaged, such as during idle), current flows through the resistor and exits through one of the light blue wires. When the ECU activates the pump in high-speed mode, the relay coil engages via a ground supplied by the green/red wire. At this point, current follows the path of least resistance through the other matching pair of light blue/red and light blue wires. Since there are two pairs of wires (light blue/red and light blue) of the same color, checking for resistance across each pair is essential to identify the correct wires. One pair should exhibit a reasonable level of resistance due to the internal resistor, while the other should be an open circuit unless the relay is triggered by supplying power and ground to the black/white and green/red wires. The process is straightforward: connect the resistor pack in line with the fuel pump wire in the vehicle. Only two wires are required for this modification, and selecting the correct pair is crucial for functionality.

To reduce the fuel flow from the external pump, a few methods can be considered. One effective approach is to implement a resistor in series with the fuel pump. This will limit the current flowing to the pump, consequently reducing its output pressure and flow rate. It is essential to select a resistor with appropriate wattage ratings to handle the power dissipation, as the pump operates at a significant current draw.

Alternatively, a PWM (Pulse Width Modulation) controller can be employed to modulate the voltage supplied to the fuel pump. This method allows for more precise control over the pump's speed and flow rate, providing flexibility for varying engine demands. The PWM controller can be configured to adjust the duty cycle, effectively controlling the average voltage and current supplied to the pump.

Furthermore, modifying the fuel return line can also influence the flow rate. By incorporating a restrictive fitting or valve in the return line, the pressure drop across the pump can be increased, resulting in reduced flow. However, care must be taken to ensure that the fuel pressure regulator can still maintain the required pressure for optimal engine performance.

In summary, reducing the flow from an external fuel pump can be achieved through the use of resistors, PWM controllers, or modifications to the fuel return line. Each method has its advantages and considerations, and the selection of the appropriate technique will depend on the specific requirements of the engine and fuel system configuration.You can get booster for fuel pumps to increase their rating, but is it possible to do anything to the wireing of an external pump to get it to flow LESS fuel Reason I ask is I am helping my brother out with an engine swap (admittidly, its not a rotary, or an RX7 for that matter). We have put a 4AGE in his KE35 carolla. The fuel system is a lift pump, surge tank and 500hp feel pump. Factory 4AGE FPR. you could run a restrictive return line back to the tank from before the regulator but thats some macgyver *. or you could trade pumps with someone with something smaller. I have a s5 na pump A note on using resistors - your pump probably pulls around 7 or 8 amps at 12 volts and 40psi.

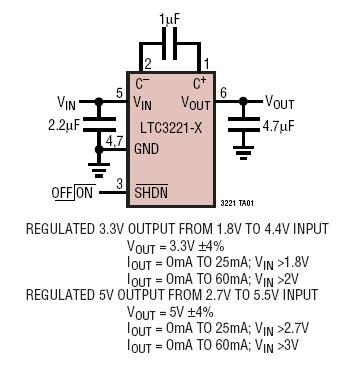

You will end up with very large wattage resistors which are not exactly cheap. you can see in this circuit diagram that, from the factory, the resistor relay is supplied voltage from the circuit opening relay through a lightblue/red wire. The wire branches off into two sections. With the resistor relay off (coil disengaged such as at idle), it passes through the resistor inside the box and comes out one of the light blue wires.

When the ECU wants to run the pump in high speed mode, the coil in the relay is engaged by a ground supplied by the Green/Red wire. The current now passes through the path of least resistance, through the other matching pair of light blue/red and light blue wires.

Because the wires are two pairs (light blue/red and light blue) of the same colors, you would want to check for resistance across each pair to determine which wires to use. One pair (the two wires you want to use) should have some decent level of resistance because it passes through the internal resistor.

I believe the other should be open circuit unless you trigger the relay by supplying power and ground to the black/white and green/red wires. It sounds more complicated than it is. just put the resistor pack inline with the fuel pump wire you have on this car. Two wires and you`re done. If you pick the wrong set, it won`t work. 🔗 External reference

To reduce the fuel flow from the external pump, a few methods can be considered. One effective approach is to implement a resistor in series with the fuel pump. This will limit the current flowing to the pump, consequently reducing its output pressure and flow rate. It is essential to select a resistor with appropriate wattage ratings to handle the power dissipation, as the pump operates at a significant current draw.

Alternatively, a PWM (Pulse Width Modulation) controller can be employed to modulate the voltage supplied to the fuel pump. This method allows for more precise control over the pump's speed and flow rate, providing flexibility for varying engine demands. The PWM controller can be configured to adjust the duty cycle, effectively controlling the average voltage and current supplied to the pump.

Furthermore, modifying the fuel return line can also influence the flow rate. By incorporating a restrictive fitting or valve in the return line, the pressure drop across the pump can be increased, resulting in reduced flow. However, care must be taken to ensure that the fuel pressure regulator can still maintain the required pressure for optimal engine performance.

In summary, reducing the flow from an external fuel pump can be achieved through the use of resistors, PWM controllers, or modifications to the fuel return line. Each method has its advantages and considerations, and the selection of the appropriate technique will depend on the specific requirements of the engine and fuel system configuration.You can get booster for fuel pumps to increase their rating, but is it possible to do anything to the wireing of an external pump to get it to flow LESS fuel Reason I ask is I am helping my brother out with an engine swap (admittidly, its not a rotary, or an RX7 for that matter). We have put a 4AGE in his KE35 carolla. The fuel system is a lift pump, surge tank and 500hp feel pump. Factory 4AGE FPR. you could run a restrictive return line back to the tank from before the regulator but thats some macgyver *. or you could trade pumps with someone with something smaller. I have a s5 na pump A note on using resistors - your pump probably pulls around 7 or 8 amps at 12 volts and 40psi.

You will end up with very large wattage resistors which are not exactly cheap. you can see in this circuit diagram that, from the factory, the resistor relay is supplied voltage from the circuit opening relay through a lightblue/red wire. The wire branches off into two sections. With the resistor relay off (coil disengaged such as at idle), it passes through the resistor inside the box and comes out one of the light blue wires.

When the ECU wants to run the pump in high speed mode, the coil in the relay is engaged by a ground supplied by the Green/Red wire. The current now passes through the path of least resistance, through the other matching pair of light blue/red and light blue wires.

Because the wires are two pairs (light blue/red and light blue) of the same colors, you would want to check for resistance across each pair to determine which wires to use. One pair (the two wires you want to use) should have some decent level of resistance because it passes through the internal resistor.

I believe the other should be open circuit unless you trigger the relay by supplying power and ground to the black/white and green/red wires. It sounds more complicated than it is. just put the resistor pack inline with the fuel pump wire you have on this car. Two wires and you`re done. If you pick the wrong set, it won`t work. 🔗 External reference