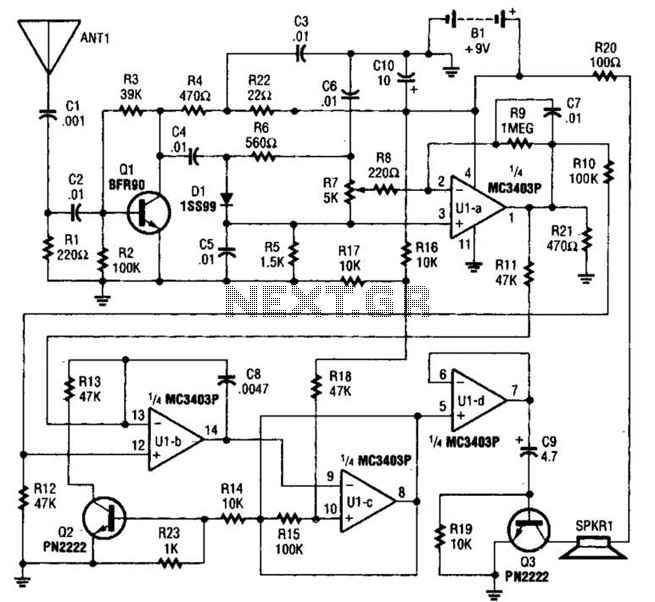

Solid State Radiation Detector with LCD Complete

A PIC microcontroller and an LCD have been integrated into a basic radiation detector, enabling the display of total counts over a 24-hour period or counts per second, as well as the relative gamma strike energy level. The energy level fluctuates because each gamma strike does not dislodge the maximum number of charge carriers. The maximum value recorded every second is utilized.

The integration of a PIC microcontroller into a radiation detection system enhances its functionality by allowing for real-time data display and analysis. The microcontroller processes input from radiation sensors, converting detected radiation events into digital signals that can be interpreted and displayed on an LCD screen.

The LCD provides a user-friendly interface, displaying critical information such as the total counts of radiation detected over a specified time frame, which can be set to a maximum of 24 hours. This feature is particularly useful for monitoring radiation levels over extended periods, enabling users to assess exposure and track changes in radiation levels.

Additionally, the system calculates and displays the counts per second (CPS), offering immediate feedback on the intensity of radiation present in the environment. This metric is crucial for users who require real-time monitoring, such as researchers or safety personnel in environments where radiation exposure is a concern.

The relative gamma strike energy level is another significant aspect of this enhanced detector. By measuring the energy associated with each gamma strike, the system provides insights into the nature of the radiation source. The variability in energy levels is attributed to the fact that not every gamma strike dislodges the maximum number of charge carriers, which affects the readings. The microcontroller is programmed to take the maximum value registered every second, ensuring that the displayed energy level reflects the highest detected intensity, thus providing a reliable measurement for analysis.

Overall, the combination of a PIC microcontroller and an LCD in this radiation detector represents a significant advancement in the capability of the device, allowing for comprehensive monitoring and analysis of radiation levels in various environments.I added a PIC and LCD to my basic radiation detector and can now display total counts over time(up to 24 hours) or Counts/Sec and relative gamma strike energy level. The energy level varies as every gamma strike does not dislodge the maximum possible number of charge carriers.

I take the maximum value registered every second and. 🔗 External reference

The integration of a PIC microcontroller into a radiation detection system enhances its functionality by allowing for real-time data display and analysis. The microcontroller processes input from radiation sensors, converting detected radiation events into digital signals that can be interpreted and displayed on an LCD screen.

The LCD provides a user-friendly interface, displaying critical information such as the total counts of radiation detected over a specified time frame, which can be set to a maximum of 24 hours. This feature is particularly useful for monitoring radiation levels over extended periods, enabling users to assess exposure and track changes in radiation levels.

Additionally, the system calculates and displays the counts per second (CPS), offering immediate feedback on the intensity of radiation present in the environment. This metric is crucial for users who require real-time monitoring, such as researchers or safety personnel in environments where radiation exposure is a concern.

The relative gamma strike energy level is another significant aspect of this enhanced detector. By measuring the energy associated with each gamma strike, the system provides insights into the nature of the radiation source. The variability in energy levels is attributed to the fact that not every gamma strike dislodges the maximum number of charge carriers, which affects the readings. The microcontroller is programmed to take the maximum value registered every second, ensuring that the displayed energy level reflects the highest detected intensity, thus providing a reliable measurement for analysis.

Overall, the combination of a PIC microcontroller and an LCD in this radiation detector represents a significant advancement in the capability of the device, allowing for comprehensive monitoring and analysis of radiation levels in various environments.I added a PIC and LCD to my basic radiation detector and can now display total counts over time(up to 24 hours) or Counts/Sec and relative gamma strike energy level. The energy level varies as every gamma strike does not dislodge the maximum possible number of charge carriers.

I take the maximum value registered every second and. 🔗 External reference