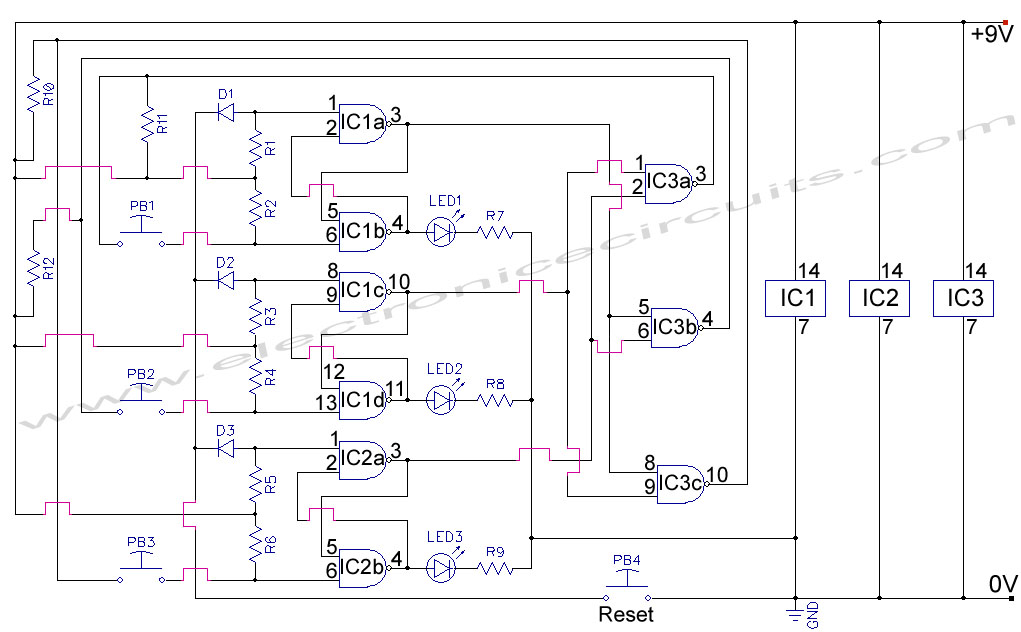

Solid-state relays control the motor forward and reverse operation circuit

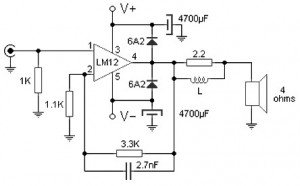

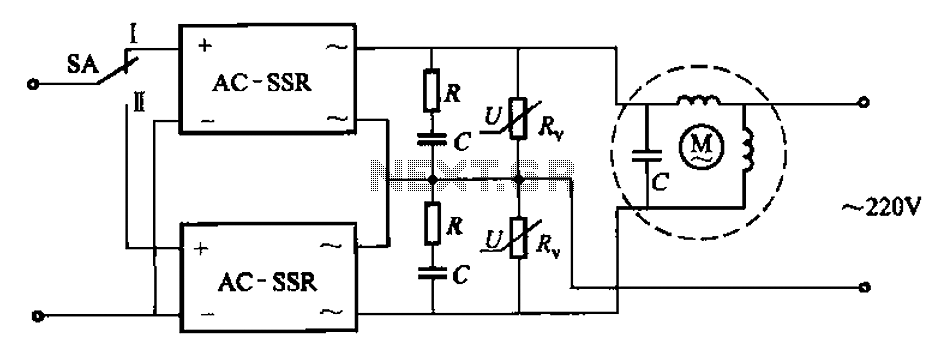

The circuit illustrated in Figure 3-14 features a SA switch positioned in the work state, allowing for motor operation. When the SA switch is set to the reverse position, the motor's direction is inverted. Additionally, an over-voltage protection element is included in the design, along with RC and R components, as indicated in Figure 3-13.

The circuit operates by utilizing a single-pole double-throw (SPDT) switch, referred to as the SA switch, which allows the user to toggle between the forward and reverse states of the motor. In the work position, the switch completes the circuit to the motor, enabling it to run in the forward direction. Conversely, when the switch is flipped to the reverse position, the polarity of the voltage applied to the motor terminals is reversed, causing the motor to rotate in the opposite direction.

To protect the circuit from over-voltage conditions, an over-voltage protection element is incorporated. This element is critical in safeguarding the motor and associated circuitry from voltage spikes that could potentially cause damage. The design of the over-voltage protection may include components such as zener diodes or transient voltage suppressors (TVS), which can clamp excessive voltage and direct it safely to ground.

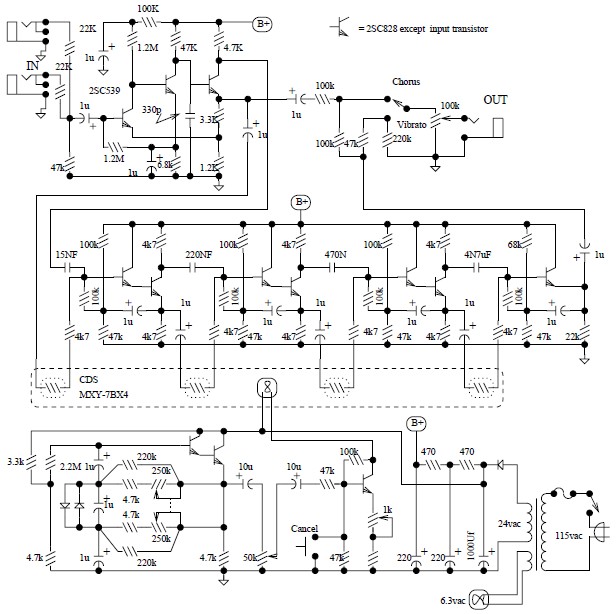

In addition to the over-voltage protection, the circuit includes resistive-capacitive (RC) networks and resistors (R) as indicated in Figure 3-13. These components may be used for various purposes, including filtering, timing, or signal conditioning, depending on the specific application requirements. The RC network can help in smoothing out voltage variations and providing stability to the circuit operation.

Overall, this circuit design is suitable for applications requiring controlled motor direction with built-in protection mechanisms, ensuring reliable operation under various electrical conditions. Circuit shown in Figure 3-14. SA switch placed in the work position, the motor is transferred; SA placed bit is set, reverse the motor. Drawing, over-voltage protection element RC and R, with the choice of Figure 3-13.

The circuit operates by utilizing a single-pole double-throw (SPDT) switch, referred to as the SA switch, which allows the user to toggle between the forward and reverse states of the motor. In the work position, the switch completes the circuit to the motor, enabling it to run in the forward direction. Conversely, when the switch is flipped to the reverse position, the polarity of the voltage applied to the motor terminals is reversed, causing the motor to rotate in the opposite direction.

To protect the circuit from over-voltage conditions, an over-voltage protection element is incorporated. This element is critical in safeguarding the motor and associated circuitry from voltage spikes that could potentially cause damage. The design of the over-voltage protection may include components such as zener diodes or transient voltage suppressors (TVS), which can clamp excessive voltage and direct it safely to ground.

In addition to the over-voltage protection, the circuit includes resistive-capacitive (RC) networks and resistors (R) as indicated in Figure 3-13. These components may be used for various purposes, including filtering, timing, or signal conditioning, depending on the specific application requirements. The RC network can help in smoothing out voltage variations and providing stability to the circuit operation.

Overall, this circuit design is suitable for applications requiring controlled motor direction with built-in protection mechanisms, ensuring reliable operation under various electrical conditions. Circuit shown in Figure 3-14. SA switch placed in the work position, the motor is transferred; SA placed bit is set, reverse the motor. Drawing, over-voltage protection element RC and R, with the choice of Figure 3-13.