spark generator

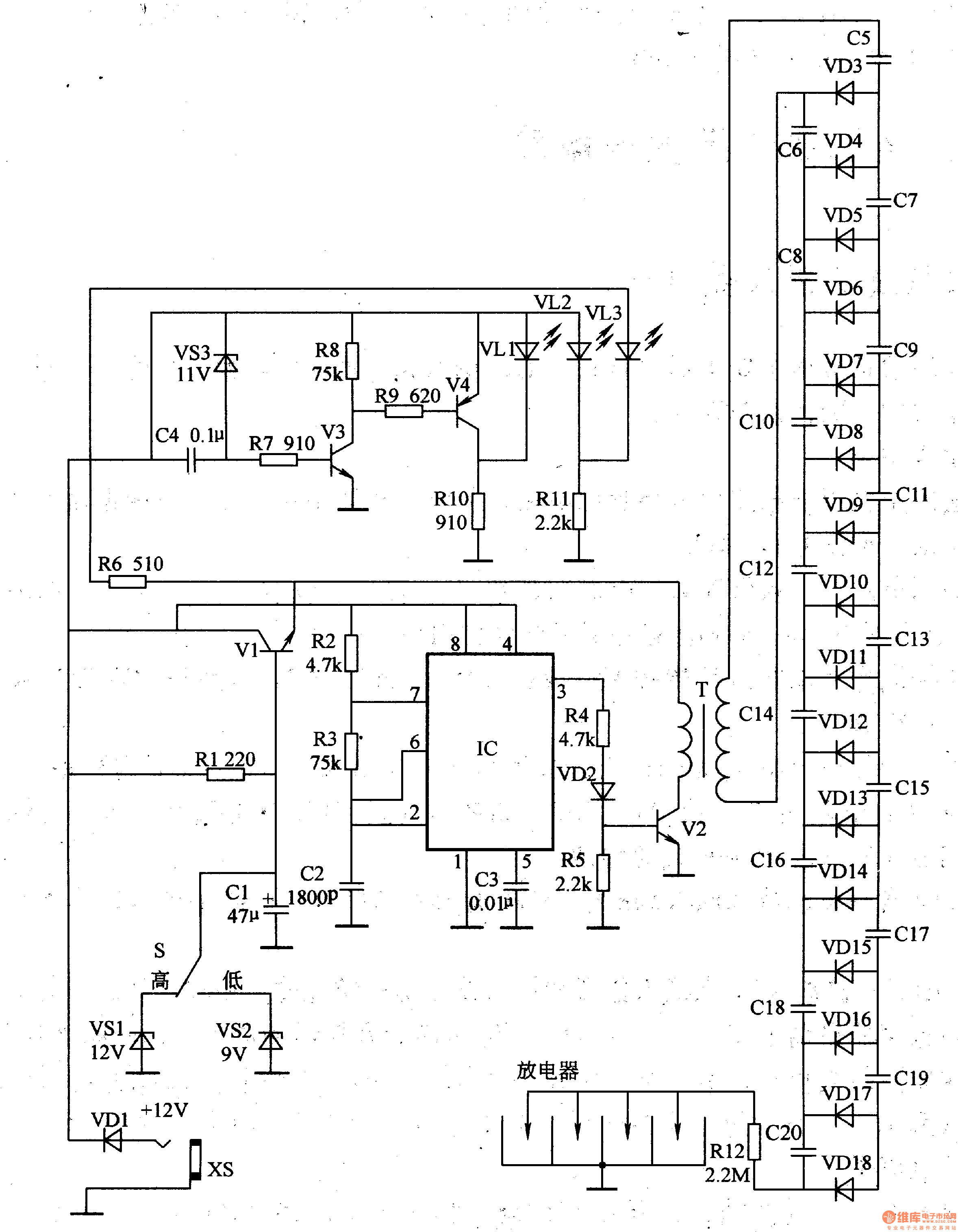

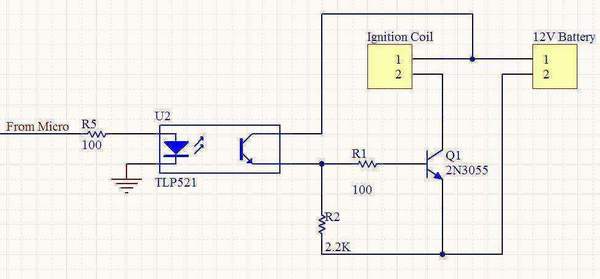

A 12V motorcycle battery and a car ignition coil are utilized in this project. A microcontroller generates pulses to the base of a 2N3055 transistor, which switches the primary of the ignition coil on and off, producing the desired sound between the probe and the surface. The use of a TV flyback transformer instead of an ignition coil is suggested for size efficiency. A powerful power source is necessary for this device, with a regulated power supply drawing more than 3A in various situations. The circuit can be minimized by using smaller ignition coils, such as those from motorcycles or small four-cylinder engines. The sound produced depends on the energy dissipated by the spark, which is determined by the energy stored in the inductor. The project aims to generate sound on metallic surfaces using a spark, with the intention of calculating the travel distance to three microphones to determine the coordinates of the point on the surface. This project is referred to as "Sonic CMM."

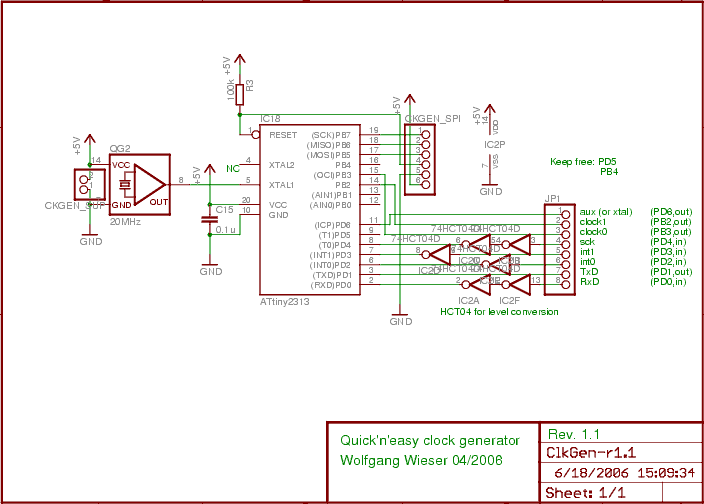

The electronic schematic for the described project involves several key components, including a 12V power supply, a microcontroller, a 2N3055 transistor, and an ignition coil or flyback transformer. The microcontroller is programmed to generate a series of pulses that control the base of the 2N3055 transistor. This transistor acts as a switch, allowing current to flow through the primary winding of the ignition coil or flyback transformer, which generates a high-voltage spark.

The ignition coil or flyback transformer is selected based on the desired output size and the application. A TV flyback transformer is particularly useful due to its compact size and built-in voltage tripler, which increases the output voltage, thereby enhancing the spark's energy. The energy stored in the coil can be calculated using the formula \(E = \frac{1}{2} L I^2\), where \(L\) is the inductance and \(I\) is the current through the coil. This energy is crucial for determining the characteristics of the sound produced.

To achieve the desired sound on metallic surfaces, the circuit must be designed to minimize electromagnetic interference, which can affect the quality of the sound. The arrangement of the components, including the placement of the probe and the microphones, is critical for accurate sound measurement and location determination. The project aims to create a system where the sound generated by the spark can be used to calculate the coordinates of points on the surface, effectively turning it into a Coordinate Measuring Machine (CMM).

In summary, the schematic involves connecting the 12V battery to the microcontroller, which outputs the control signals to the base of the 2N3055 transistor. The collector of the transistor connects to the ignition coil or flyback transformer, with the secondary winding connected to the probe that interacts with the metallic surface. The design must ensure that the generated spark is sufficient to produce audible sound while maintaining precision in the measurements taken by the microphones.Used a 12V motorcylce Battery and an ignition coil of a car. A microcontroller produces some pulses to the base of a 2N3055 transistor. 2N3055 turn on an off the primary of the coil and the desirable sound is produced between the probe and the surface. I have used a 12V motorcylce Battery and an ignition coil of a car. A microcontroller produces some pulses to the base of a 2N3055 transistor. 2N3055 turn on an off the primary of the coil and the desirable sound is produced between the probe and the surface. I used a TV flyback transformer instead of an ignition coil, so the size was reasonable. You need a powerful power source for a such device. so you have to use a massive battery. I used my regulated power supply and the device drew more than 3A at several situations. I have used a 12V motorcylce Battery and an ignition coil of a car. A microcontroller produces some pulses to the base of a 2N3055 transistor. 2N3055 turn on an off the primary of the coil and the desirable sound is produced between the probe and the surface.

Could you please post a schematic You may be able to reduce the volume of the circuit by using an ignition coil from a small engine, such as from a motorcycle or small 4-cyl engine. How far does the spark need to jump Electric fence circuits for animals use small transformers and spark the way you want.

Perhaps a small xenon transformer would be in order for small sparks Any coil whose current is interrupted will make a spark. The audible part probably depends on the energy dumped by the spark. The energy stored in an inductor is (1/2) ·L ·I ². I know the spark made by old time car ignition coils had a "pop-pop" sound. A lawnmower coil may also have this but you can`t hear it over the engine noise. Could you please post a schematic You may be able to reduce the volume of the circuit by using an ignition coil from a small engine, such as from a motorcycle or small 4-cyl engine.

How far does the spark need to jump Electric fence circuits for animals use small transformers and spark the way you want. Perhaps a small xenon transformer would be in order for small sparks anyhow you can use a TV or a monitor flyback transformer to generate a nice arc.

today most of them have a built-in Tripler or casked which multiples the high voltage by factor of 3. The built-in Tripler reduces the size of the flyback too. My goal is producing a sound ON the metalic surfaces. Formerly, I thought that making spark on metalic surfaces is a good solution. but now I have many problems with the dimesion and of course, the electromagnic noise I want to produce the sound on the surfaces with a probe and calculate the travelling distance to three microphones.

thereby, the coordinate of that point on the surface is specified. I call this project "Sonic CMM". My goal is producing a sound ON the metalic surfaces. Formerly, I thought that making spark on metalic surfaces is a good solution. but now I have many problems with the dimesion and of course, the electromagnic noise I want to produce the sound on the surfaces with a probe and calculate the travelling distance to three microphones. thereby, the coordinate of that point on the surface is specified. I call this project "Sonic CMM". Do you want the metallic surface to vibrate due to the arc and crenates the audible sound, or you want the Arc itself to vibrate and generates audible sound (Due to the expanding and scrunching of the air molecules ) Do you want the metallic surface to vibrate due to the arc and crenates the audible sound, or you want the Arc itself to vibrate and generates audible sound (Due to the expanding and scrunching of the air molecules ) No, my mean for the surface is a surface of a metalic and solid part.

I just want a sound is produced on the surface of that part by means of something like spark (or maybe other device Coordinate Measuring Machines (CMM) are used for measuring the shape of obj 🔗 External reference

The electronic schematic for the described project involves several key components, including a 12V power supply, a microcontroller, a 2N3055 transistor, and an ignition coil or flyback transformer. The microcontroller is programmed to generate a series of pulses that control the base of the 2N3055 transistor. This transistor acts as a switch, allowing current to flow through the primary winding of the ignition coil or flyback transformer, which generates a high-voltage spark.

The ignition coil or flyback transformer is selected based on the desired output size and the application. A TV flyback transformer is particularly useful due to its compact size and built-in voltage tripler, which increases the output voltage, thereby enhancing the spark's energy. The energy stored in the coil can be calculated using the formula \(E = \frac{1}{2} L I^2\), where \(L\) is the inductance and \(I\) is the current through the coil. This energy is crucial for determining the characteristics of the sound produced.

To achieve the desired sound on metallic surfaces, the circuit must be designed to minimize electromagnetic interference, which can affect the quality of the sound. The arrangement of the components, including the placement of the probe and the microphones, is critical for accurate sound measurement and location determination. The project aims to create a system where the sound generated by the spark can be used to calculate the coordinates of points on the surface, effectively turning it into a Coordinate Measuring Machine (CMM).

In summary, the schematic involves connecting the 12V battery to the microcontroller, which outputs the control signals to the base of the 2N3055 transistor. The collector of the transistor connects to the ignition coil or flyback transformer, with the secondary winding connected to the probe that interacts with the metallic surface. The design must ensure that the generated spark is sufficient to produce audible sound while maintaining precision in the measurements taken by the microphones.Used a 12V motorcylce Battery and an ignition coil of a car. A microcontroller produces some pulses to the base of a 2N3055 transistor. 2N3055 turn on an off the primary of the coil and the desirable sound is produced between the probe and the surface. I have used a 12V motorcylce Battery and an ignition coil of a car. A microcontroller produces some pulses to the base of a 2N3055 transistor. 2N3055 turn on an off the primary of the coil and the desirable sound is produced between the probe and the surface. I used a TV flyback transformer instead of an ignition coil, so the size was reasonable. You need a powerful power source for a such device. so you have to use a massive battery. I used my regulated power supply and the device drew more than 3A at several situations. I have used a 12V motorcylce Battery and an ignition coil of a car. A microcontroller produces some pulses to the base of a 2N3055 transistor. 2N3055 turn on an off the primary of the coil and the desirable sound is produced between the probe and the surface.

Could you please post a schematic You may be able to reduce the volume of the circuit by using an ignition coil from a small engine, such as from a motorcycle or small 4-cyl engine. How far does the spark need to jump Electric fence circuits for animals use small transformers and spark the way you want.

Perhaps a small xenon transformer would be in order for small sparks Any coil whose current is interrupted will make a spark. The audible part probably depends on the energy dumped by the spark. The energy stored in an inductor is (1/2) ·L ·I ². I know the spark made by old time car ignition coils had a "pop-pop" sound. A lawnmower coil may also have this but you can`t hear it over the engine noise. Could you please post a schematic You may be able to reduce the volume of the circuit by using an ignition coil from a small engine, such as from a motorcycle or small 4-cyl engine.

How far does the spark need to jump Electric fence circuits for animals use small transformers and spark the way you want. Perhaps a small xenon transformer would be in order for small sparks anyhow you can use a TV or a monitor flyback transformer to generate a nice arc.

today most of them have a built-in Tripler or casked which multiples the high voltage by factor of 3. The built-in Tripler reduces the size of the flyback too. My goal is producing a sound ON the metalic surfaces. Formerly, I thought that making spark on metalic surfaces is a good solution. but now I have many problems with the dimesion and of course, the electromagnic noise I want to produce the sound on the surfaces with a probe and calculate the travelling distance to three microphones.

thereby, the coordinate of that point on the surface is specified. I call this project "Sonic CMM". My goal is producing a sound ON the metalic surfaces. Formerly, I thought that making spark on metalic surfaces is a good solution. but now I have many problems with the dimesion and of course, the electromagnic noise I want to produce the sound on the surfaces with a probe and calculate the travelling distance to three microphones. thereby, the coordinate of that point on the surface is specified. I call this project "Sonic CMM". Do you want the metallic surface to vibrate due to the arc and crenates the audible sound, or you want the Arc itself to vibrate and generates audible sound (Due to the expanding and scrunching of the air molecules ) Do you want the metallic surface to vibrate due to the arc and crenates the audible sound, or you want the Arc itself to vibrate and generates audible sound (Due to the expanding and scrunching of the air molecules ) No, my mean for the surface is a surface of a metalic and solid part.

I just want a sound is produced on the surface of that part by means of something like spark (or maybe other device Coordinate Measuring Machines (CMM) are used for measuring the shape of obj 🔗 External reference