Stablised Power Supply With Short-Circuit Indication

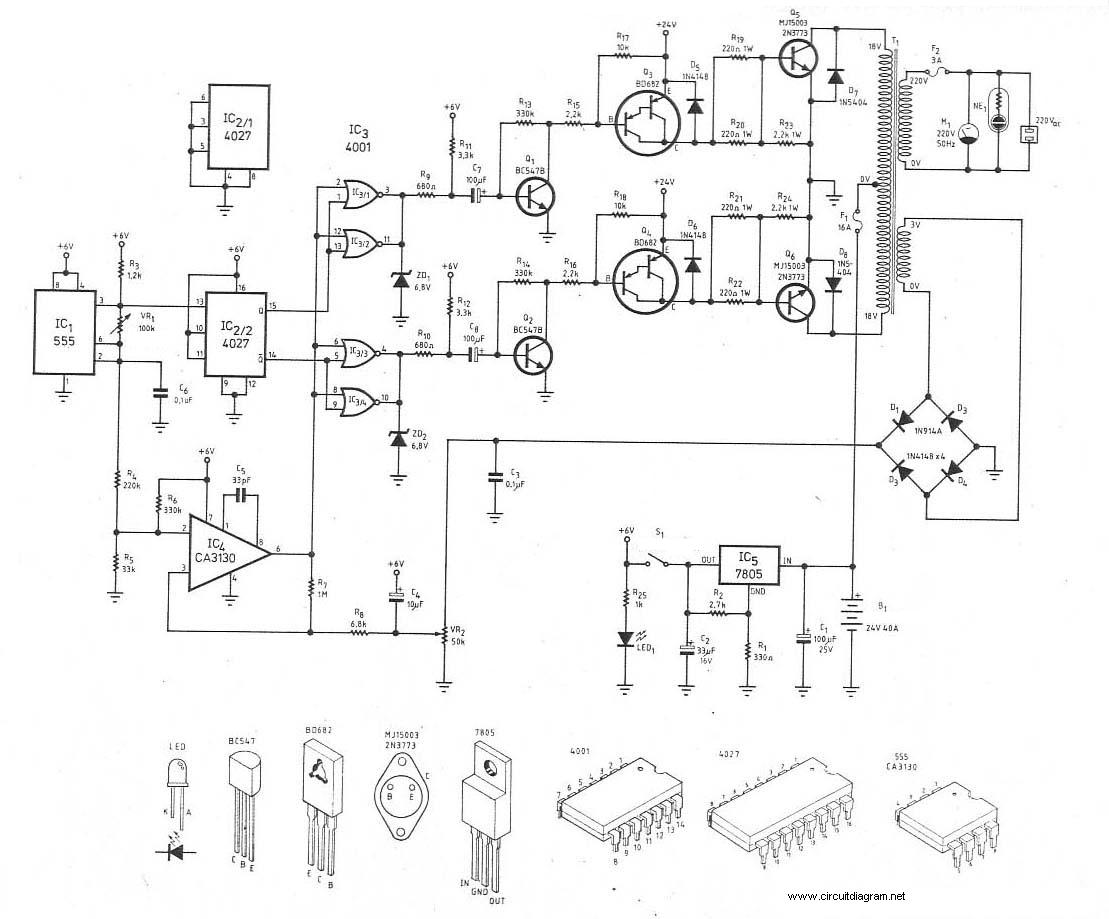

This is an efficient four-stage stabilized power supply unit designed for testing electronic circuits. It delivers well-regulated and stabilized outputs, which are crucial for achieving accurate results in most electronic applications. The circuit features an audio-visual indication system that alerts users to any short circuits on the printed circuit board (PCB) under test, allowing for immediate power cut-off to protect valuable components from damage. It offers four selectable regulated outputs (12V, 9V, 6V, and 5V) along with an unregulated 18V output, controlled via a rotary switch (S2). The selected output is displayed on an analog voltmeter connected to the output rails. The power supply utilizes a standard 18V-0-18V, 500mA step-down transformer to generate 18V AC, which is rectified to 18V DC by a diode rectifier (D1 and D2). The DC voltage is smoothed by capacitor C1 and supplied to a combination of regulator integrated circuits (IC1 through IC4), producing fixed regulated outputs of 12V, 9V, 6V, and 5V, connected to the rotary switch contacts. This power supply can cater to loads requiring up to 200mA of current. Complementary transistors (T1 and T2) activate when the circuit is powered on, providing the full selected supply voltage at the collector of transistor T2 to power the load. An LED (LED3) indicates the presence of output voltage. The negative terminal of a piezo-buzzer (PZ1) is connected to the output rail through another LED (LED2), which keeps the buzzer silent when the negative terminal is at full supply voltage. In the event of a short circuit at the output, LED2 illuminates to activate the piezo-buzzer. A fuse-failure indicator distinguishes between a short circuit at the output and input failure, utilizing a bicolor LED (LED1) and resistors (R1 and R2). When power is available and the fuse is intact, both red and green halves of LED1 illuminate, producing a yellowish light. If the fuse fails, the green LED turns off, and the red LED lights up to signal a fuse breakdown. The circuit can be easily assembled on a general-purpose PCB, with small heat sinks recommended for all ICs to aid in heat dissipation. The output voltage can be monitored using a voltmeter. It is advisable to enclose the circuit in a metal box that accommodates the voltmeter, LEDs, rotary switch, and other components.

The design of this power supply unit is structured to ensure reliability and safety during operation. The use of a step-down transformer allows for efficient conversion of AC voltage to a lower DC voltage, which is necessary for powering various electronic devices. The inclusion of multiple output voltages enhances the versatility of the power supply, making it suitable for different testing scenarios.

The rectification process is facilitated by diodes D1 and D2, which convert the AC voltage to DC. Capacitor C1 plays a crucial role in smoothing the rectified voltage, minimizing ripples, and ensuring a stable output. The regulator ICs (IC1 to IC4) are critical components that maintain the output voltage at fixed levels, irrespective of variations in input voltage or load conditions. These ICs should be selected based on their current handling capabilities, ensuring they can adequately support the maximum load of 200mA.

Transistors T1 and T2 are used for switching and amplifying the output signal. Their complementary configuration allows for efficient control of the output voltage, and the presence of LED3 provides a visual confirmation of output availability, enhancing user interaction with the device.

The audio-visual indication system, comprising LED2 and the piezo-buzzer PZ1, is vital for immediate feedback on circuit conditions. This feature is particularly important during testing phases, as it alerts the user to potential issues, allowing for prompt corrective actions to prevent component damage.

The fuse-failure indicator, with its bicolor LED, serves as an essential safety feature, providing clear visual feedback regarding the operational status of the fuse. This allows users to quickly identify and address any issues that may arise during testing.

In conclusion, the design of this stabilized power supply unit emphasizes safety, versatility, and ease of use, making it an invaluable tool for electronics testing and development. Proper assembly on a PCB, along with effective heat management and enclosure considerations, will further enhance the performance and longevity of the circuit.Here is an efficient 4-stage stabilised power supply unit for testing electronic circuits. It provides well regulated and stabilised output, which is essential for most electronic circuits to give proper results. The circuit provides an audio-visual indication if there is a short circuit in the PCB under test, so the power supply to the circuit un

der test` can be cut-off immediately to save the valuable components from damage. The circuit provides four different regulated outputs (12V, 9V, 6V and 5V) and an unregulated 18V output, which are selectable through rotary switch S2. The selected output is indicated on the analogue voltmeter connected to the outputs rails. The circuit uses a standard 18V-0-18V, 500mA step-down transformer to generate 18V AC. A rectifier diode comprising diodes D1 and D2 provides 18V DC, which is smoothed by capacitor C1 and given to the combination of regulator ICs (IC1 through IC4).

The regulator ICs produce fixed, regulated outputs of 12V, 9V, 6V and 5V, respectively, which are connected to the rotary switch contacts. This power supply is useful for loads requiring up to 200mA current. Complementary transistors T1 and T2 conduct when the power to the circuit is switched on. Full selected supply voltage is available at the collector of transistor T2, which is used to power the load.

LED3 indicates the presence of output voltage. The negative terminal of piezo-buzzer PZ1 is connected to the output rail via LED2, so the piezo-buzzer remains silent as its negative terminal is also at full supply voltage (selected). If there is a short circuit at the output, LED2 glows to activate the piezo-buzzer. A fuse-failure indicator distinguishes short circuit at the output and input failure. It consists of a bicolour LED (LED1) and resistors R1 and R2. When power is available and the fuse is intact, red and green halves of LED1 are effectively in parallel to output a yellowish light.

When fuse fails, green LED goes off and red LED lights up to indicate fuse breakdown. The circuit can be easily constructed on a general-purpose PCB. Use small heat-sinks for all ICs to dissipate heat. The output voltage can be read on a voltmeter. Enclose the circuit in a metal box with provisions for voltmeter, LEDs, rotary switch, etc. 🔗 External reference

The design of this power supply unit is structured to ensure reliability and safety during operation. The use of a step-down transformer allows for efficient conversion of AC voltage to a lower DC voltage, which is necessary for powering various electronic devices. The inclusion of multiple output voltages enhances the versatility of the power supply, making it suitable for different testing scenarios.

The rectification process is facilitated by diodes D1 and D2, which convert the AC voltage to DC. Capacitor C1 plays a crucial role in smoothing the rectified voltage, minimizing ripples, and ensuring a stable output. The regulator ICs (IC1 to IC4) are critical components that maintain the output voltage at fixed levels, irrespective of variations in input voltage or load conditions. These ICs should be selected based on their current handling capabilities, ensuring they can adequately support the maximum load of 200mA.

Transistors T1 and T2 are used for switching and amplifying the output signal. Their complementary configuration allows for efficient control of the output voltage, and the presence of LED3 provides a visual confirmation of output availability, enhancing user interaction with the device.

The audio-visual indication system, comprising LED2 and the piezo-buzzer PZ1, is vital for immediate feedback on circuit conditions. This feature is particularly important during testing phases, as it alerts the user to potential issues, allowing for prompt corrective actions to prevent component damage.

The fuse-failure indicator, with its bicolor LED, serves as an essential safety feature, providing clear visual feedback regarding the operational status of the fuse. This allows users to quickly identify and address any issues that may arise during testing.

In conclusion, the design of this stabilized power supply unit emphasizes safety, versatility, and ease of use, making it an invaluable tool for electronics testing and development. Proper assembly on a PCB, along with effective heat management and enclosure considerations, will further enhance the performance and longevity of the circuit.Here is an efficient 4-stage stabilised power supply unit for testing electronic circuits. It provides well regulated and stabilised output, which is essential for most electronic circuits to give proper results. The circuit provides an audio-visual indication if there is a short circuit in the PCB under test, so the power supply to the circuit un

der test` can be cut-off immediately to save the valuable components from damage. The circuit provides four different regulated outputs (12V, 9V, 6V and 5V) and an unregulated 18V output, which are selectable through rotary switch S2. The selected output is indicated on the analogue voltmeter connected to the outputs rails. The circuit uses a standard 18V-0-18V, 500mA step-down transformer to generate 18V AC. A rectifier diode comprising diodes D1 and D2 provides 18V DC, which is smoothed by capacitor C1 and given to the combination of regulator ICs (IC1 through IC4).

The regulator ICs produce fixed, regulated outputs of 12V, 9V, 6V and 5V, respectively, which are connected to the rotary switch contacts. This power supply is useful for loads requiring up to 200mA current. Complementary transistors T1 and T2 conduct when the power to the circuit is switched on. Full selected supply voltage is available at the collector of transistor T2, which is used to power the load.

LED3 indicates the presence of output voltage. The negative terminal of piezo-buzzer PZ1 is connected to the output rail via LED2, so the piezo-buzzer remains silent as its negative terminal is also at full supply voltage (selected). If there is a short circuit at the output, LED2 glows to activate the piezo-buzzer. A fuse-failure indicator distinguishes short circuit at the output and input failure. It consists of a bicolour LED (LED1) and resistors R1 and R2. When power is available and the fuse is intact, red and green halves of LED1 are effectively in parallel to output a yellowish light.

When fuse fails, green LED goes off and red LED lights up to indicate fuse breakdown. The circuit can be easily constructed on a general-purpose PCB. Use small heat-sinks for all ICs to dissipate heat. The output voltage can be read on a voltmeter. Enclose the circuit in a metal box with provisions for voltmeter, LEDs, rotary switch, etc. 🔗 External reference