Temperature Controlled NICD Charger IC LM311

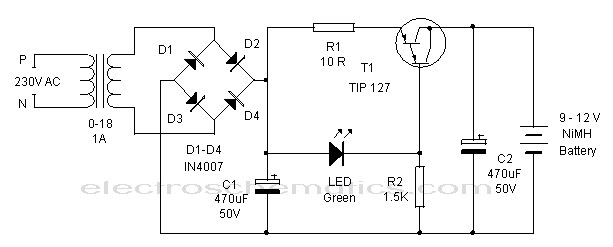

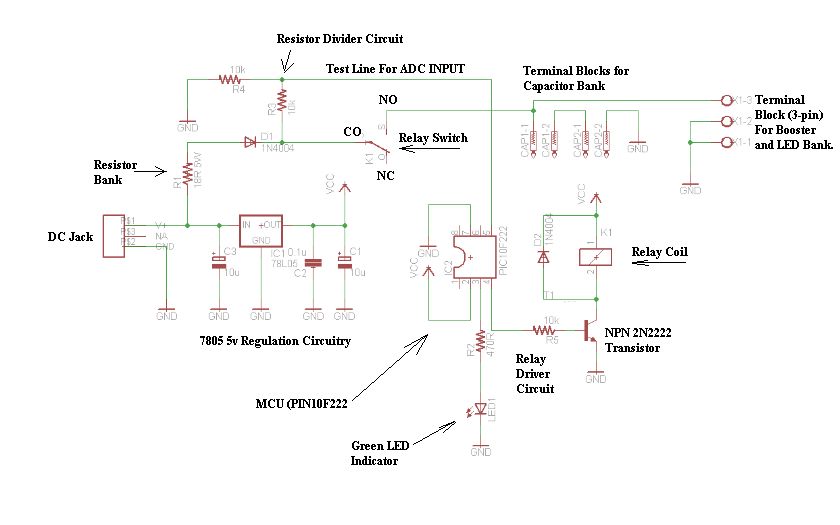

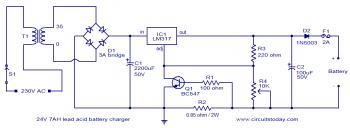

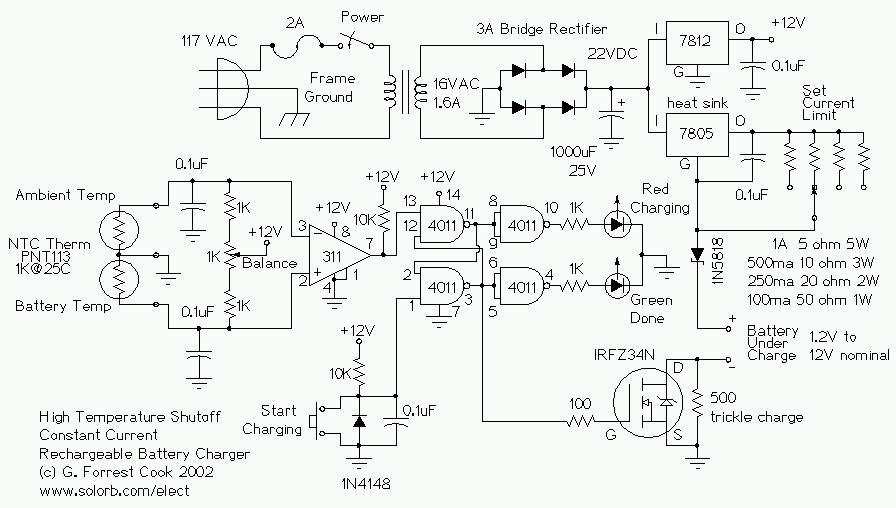

This circuit is designed for a temperature-controlled constant current battery charger, compatible with NiCd, NiMH, and other rechargeable cells. It operates on the principle that most rechargeable batteries exhibit an increase in temperature when they are fully charged. Overcharging is a primary cause of reduced cell lifespan, as overheated cells can rupture their internal seals and vent out electrolyte. As cells dry out, they lose capacity. The circuit utilizes a transformer, bridge rectifier, and a 1000µF capacitor to provide approximately 22 volts of DC power for the operation of the remaining components. A 7812 voltage regulator reduces this voltage to 12 volts to power the 311 comparator and 4011 NAND gates. Pressing the start switch initiates the charging cycle, activating the two 4011 NAND gates configured as an R-S flip-flop, which transitions the circuit into charging mode. The red LED illuminates, and the VMOS FET current switch is activated, allowing charging current to flow through the battery pack. If the battery is warmer than the reference temperature, the circuit will not enter charging mode, necessitating that the pack cool down first. Once the battery pack reaches a fully charged state, the differential temperature sensor triggers the flip-flop to turn off, deactivating the VMOS current switch and illuminating the green LED. A 7805 voltage regulator is configured as a constant current regulator, providing a safe maximum charge current suitable for various cell types. A 500-ohm resistor across the VMOS FET sets the trickle charge current that continues to flow through the battery pack after the bulk charging phase is complete. The differential temperature sensor circuit operates by presenting two voltages to the input of the 311 comparator. The comparator output toggles on or off based on which input voltage is higher. As the thermistors heat up, their resistance decreases, resulting in lower voltage at the associated comparator input. With two sensors in place, the circuit is designed to respond only to the temperature difference between them, accommodating variations in room temperature.

This temperature-controlled constant current battery charger circuit is a sophisticated solution for maintaining the health and longevity of rechargeable batteries. The core principle revolves around monitoring the temperature of the cells during charging, ensuring they are not subjected to overcharging conditions that could lead to damage. The use of a transformer and bridge rectifier enables the conversion of AC voltage to a stable DC output, which is essential for charging operations.

The 7812 voltage regulator plays a crucial role in stabilizing the voltage supplied to the comparator and logic gates, ensuring consistent performance of the control circuitry. The R-S flip-flop configuration using the 4011 NAND gates allows for a simple yet effective method of controlling the charging state based on the input from the start switch and the temperature sensor.

In terms of safety features, the circuit is designed to prevent charging if the battery temperature exceeds a predefined threshold. This feature is critical in avoiding potential hazards associated with overheating batteries. The use of a differential temperature sensor enhances the circuit's ability to adapt to varying environmental conditions, ensuring that it only responds to significant changes in battery temperature, thus optimizing the charging process.

The 7805 voltage regulator's role as a constant current regulator is vital, as it ensures that the charging current remains within safe limits for different types of batteries. The adjustable trickle charge current, set by the 500-ohm resistor, provides a gentle finish to the charging process, allowing the batteries to reach full capacity without stress.

Overall, this circuit exemplifies a well-thought-out design that balances efficiency, safety, and adaptability, making it suitable for various rechargeable battery technologies. The careful selection of components and the thoughtful integration of temperature monitoring ensure that batteries are charged optimally, thereby extending their operational life and reliability.This circuit is for a temperature controlled constant current battery charger. It works with NICD, NIMH, and other rechargeable cells. The circuit works on the principle that most rechargeable batteries show an increase in temperature when the cells becomes fully charged. Overcharging is one of the main causes of short cell life, hot cells pop the ir internal seals and vent out electrolyte. As cells dry out, they lose capacity. The transformer, bridge rectifier, and 1000uF capacitor provide around 22 Volts of DC power to run the rest of the circuit. The 7812 regulator drops this to 12V to run the 311 comparator and 4011 nand gates. The start switch is pressed to start the charging cycle. This causes the two 4011 nand gates, which are wired as an r-s flip-flop, to go into the charging mode.

The Red LED is lit, and the VMOS FET current switch is turned on. Charging current runs though the battery pack. If the battery starts out warmer than the reference temperature, the circuit will not switch into charging mode. Let the pack cool down. When the battery pack reaches a full state of charge, the differential temperature sensor causes the flip-flop to switch off, turning off the VMOS current switch, and lighting the Green LED.

The 7805 voltage regulator is wired as a constant current regulator. This provides a safe maximum charge current for a number of different cell types. The 500 ohm resistor across the VMOS FET sets the trickle charge current which flows through the battery pack after the bulk charging is finished. The differential temperature sensor circuit works by presenting two voltages to the input of the 311 comparator.

The comparator output switches on or off depending on which input is at a higher voltage than the other. As the thermistors warm up, their resistance drops, lowering the associated comparator input. Since there are two sensors, the room temperature can vary and the circuit will only react to the difference in temperature between the sensors.

🔗 External reference

This temperature-controlled constant current battery charger circuit is a sophisticated solution for maintaining the health and longevity of rechargeable batteries. The core principle revolves around monitoring the temperature of the cells during charging, ensuring they are not subjected to overcharging conditions that could lead to damage. The use of a transformer and bridge rectifier enables the conversion of AC voltage to a stable DC output, which is essential for charging operations.

The 7812 voltage regulator plays a crucial role in stabilizing the voltage supplied to the comparator and logic gates, ensuring consistent performance of the control circuitry. The R-S flip-flop configuration using the 4011 NAND gates allows for a simple yet effective method of controlling the charging state based on the input from the start switch and the temperature sensor.

In terms of safety features, the circuit is designed to prevent charging if the battery temperature exceeds a predefined threshold. This feature is critical in avoiding potential hazards associated with overheating batteries. The use of a differential temperature sensor enhances the circuit's ability to adapt to varying environmental conditions, ensuring that it only responds to significant changes in battery temperature, thus optimizing the charging process.

The 7805 voltage regulator's role as a constant current regulator is vital, as it ensures that the charging current remains within safe limits for different types of batteries. The adjustable trickle charge current, set by the 500-ohm resistor, provides a gentle finish to the charging process, allowing the batteries to reach full capacity without stress.

Overall, this circuit exemplifies a well-thought-out design that balances efficiency, safety, and adaptability, making it suitable for various rechargeable battery technologies. The careful selection of components and the thoughtful integration of temperature monitoring ensure that batteries are charged optimally, thereby extending their operational life and reliability.This circuit is for a temperature controlled constant current battery charger. It works with NICD, NIMH, and other rechargeable cells. The circuit works on the principle that most rechargeable batteries show an increase in temperature when the cells becomes fully charged. Overcharging is one of the main causes of short cell life, hot cells pop the ir internal seals and vent out electrolyte. As cells dry out, they lose capacity. The transformer, bridge rectifier, and 1000uF capacitor provide around 22 Volts of DC power to run the rest of the circuit. The 7812 regulator drops this to 12V to run the 311 comparator and 4011 nand gates. The start switch is pressed to start the charging cycle. This causes the two 4011 nand gates, which are wired as an r-s flip-flop, to go into the charging mode.

The Red LED is lit, and the VMOS FET current switch is turned on. Charging current runs though the battery pack. If the battery starts out warmer than the reference temperature, the circuit will not switch into charging mode. Let the pack cool down. When the battery pack reaches a full state of charge, the differential temperature sensor causes the flip-flop to switch off, turning off the VMOS current switch, and lighting the Green LED.

The 7805 voltage regulator is wired as a constant current regulator. This provides a safe maximum charge current for a number of different cell types. The 500 ohm resistor across the VMOS FET sets the trickle charge current which flows through the battery pack after the bulk charging is finished. The differential temperature sensor circuit works by presenting two voltages to the input of the 311 comparator.

The comparator output switches on or off depending on which input is at a higher voltage than the other. As the thermistors warm up, their resistance drops, lowering the associated comparator input. Since there are two sensors, the room temperature can vary and the circuit will only react to the difference in temperature between the sensors.

🔗 External reference