Ten Road temperature itinerant detecting circuit 555 CD4069 CH208

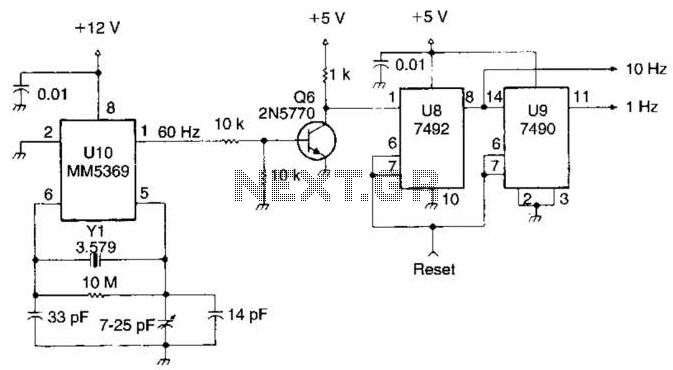

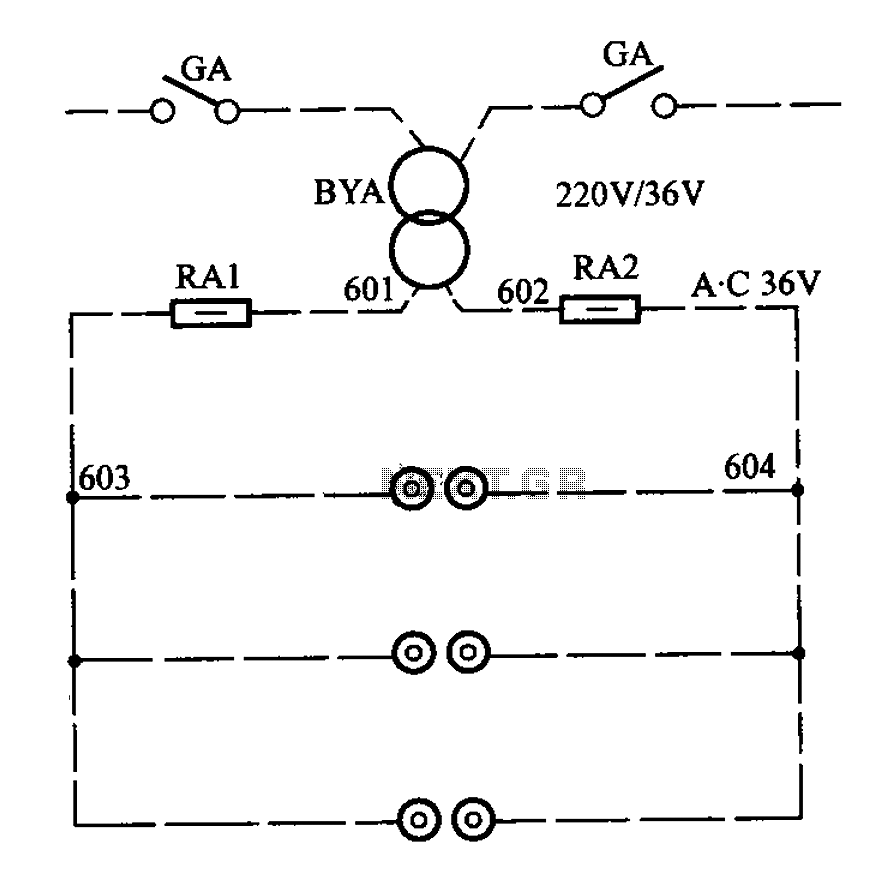

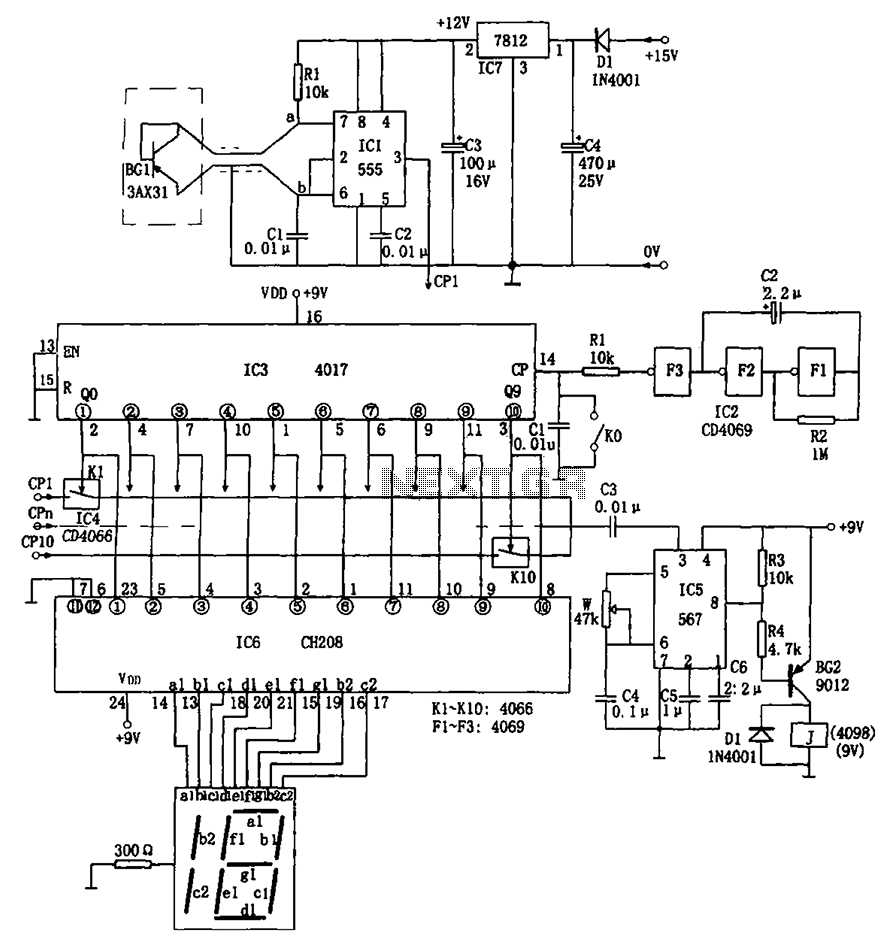

The temperature detection circuit is illustrated in Figure 10. This circuit comprises a temperature sensor, a voltage-to-frequency (V/F) converter, an oscillator, a control program for testing, an alarm system, and a decoding and display circuit. The temperature sensor used is the 3AX31, which is diode-connected. As the ambient temperature changes, the resistance of the sensor varies linearly with temperature. The oscillator is built around IC1 (555) and includes components such as resistors R1 and Rce, and capacitor C1. The oscillation frequency is determined by the formula f = 1.44 / ((R1 + 2Rce) * C1). As Rce changes linearly with temperature, the frequency f also varies proportionally, facilitating temperature-to-frequency conversion. For detecting 10 temperature points, 10 such temperature/frequency converter heads are required. IC2 employs a hex inverter (CD4069), where F1, F2, and F3 form a 0.2Hz trigger pulse generator, which sends a pulse count (CP) every 5 seconds to the counting circuit IC3. IC3 is a decimal counter/pulse distributor (CD4017), which, under the influence of CP, sequentially activates its ten output terminals Q0 to Q9 with high pulses. The corresponding analog electronic switches K1 to K10 are then turned on in sequence. IC4 utilizes analog switches (CD4066), allowing the frequency signals from K1 to K10 to be fed sequentially into a phase-locked loop circuit with an audio decoder IC5 (567). The center frequency of IC5 is set to f0 = 1 / (1.1 * Rw * C4), and the circuit capacitor C5 can be adjusted to set the locking bandwidth. If the detected temperature exceeds a predetermined limit, the output of IC5 goes low, which activates the relay J to trigger the alarm circuit. Simultaneously, the high signal outputs from IC3 (Q0 to Q9) are fed into IC6 (CH208), a decoding display circuit. After decoding, IC6 drives a common cathode LED digital tube to indicate the corresponding over-temperature condition. This detection circuit is suitable for use in various applications, including temperature detection in train axles.

The temperature detection circuit operates through a systematic integration of components that work together to monitor and respond to changes in temperature. The temperature sensor, specifically the 3AX31, is crucial for detecting ambient temperature variations. Its linear response ensures accurate readings, which are then converted into frequency signals by the V/F converter.

The oscillator, utilizing the 555 timer IC, generates a frequency that varies with the changes in resistance of the temperature sensor. This frequency is essential for the subsequent processing stages as it provides a direct correlation between temperature and frequency, enabling precise temperature measurements.

The pulse generator, built with the CD4069 inverter, provides a consistent timing signal that drives the counting mechanism in IC3. The CD4017 counter is designed to sequentially activate its outputs based on the timing pulses, allowing for a systematic approach to monitoring multiple temperature points. Each output corresponds to a specific temperature reading, which is facilitated by the analog switches in IC4.

The phase-locked loop circuit, combined with the audio decoder IC5, serves a dual purpose: it not only processes the frequency signals but also triggers an alarm when the temperature exceeds a set threshold. The adjustable locking bandwidth allows for flexibility in the system's response to temperature fluctuations.

Finally, the decoding display circuit (IC6) provides a visual representation of the temperature status through LED indicators. This feature enhances the usability of the circuit by allowing operators to quickly assess temperature conditions at a glance.

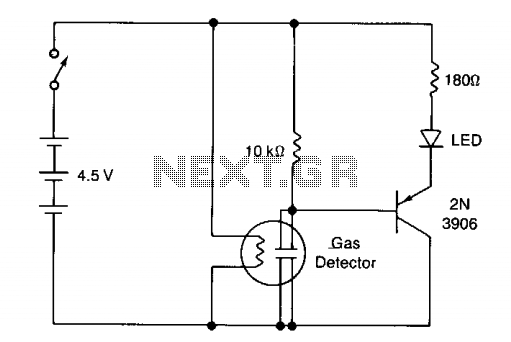

Overall, this temperature detection circuit is designed for reliability and effectiveness in monitoring temperature in critical applications, ensuring timely alerts and facilitating preventive measures in environments where temperature control is essential. As shown in Fig ten temperature detection circuit circuit. The detection circuit by the temperature sensor, V/F converter circuit, an oscillator, circuit testing program contro l, alarm, decoded and displayed circuit. Temperature sensor 3AX31, and diode-connected form. When the ambient temperature changes, the radio - sets and resistance k linearly with temperature changes. Oscillator consists of IC1 (555) and rce, R1, C1 and other components, the oscillation frequency of f 1.44/(R1 + 2rce) C1, it rce changes linearly with temperature, then f accordingly varies in proportion to, in order to achieve temperature/frequency conversion.

If the detected 10 points, need 10 such temperature/frequency converter head. Circuit IC2 use hex inverter CD4069, where F1, F2, F3 composed of 0.2Hz trigger pulse generator, which sends a pulse count CP every 5 seconds to count circuit IC3. IC3 decimal counter/pulse distributor CD4017, under CP effect, its ten output terminal Q0 ~ Q9 successively appear high pulse.

Corresponding analog electronic switch K1 ~ K10 are sequentially turned on. IC4 using analog switches CD4066, K1 ~ K10 frequency signal outputted sequentially fed into the phase locked loop circuit having an audio decoder IC5 (567) pin (IC5 wherein the center frequency is f0 1/1.1RwC4, circuit C5 adjustable given locking bandwidth), when the temperature exceeds a certain limit the scope of the road, and with a preset center frequency f0 are the same, IC5 output low (since feet), making BG conduction, the relay J pull the trigger alarm circuit, alarm anthracene ring. At the same time, Q0 ~ Q9 high signal output of IC3 in turn fed IC6 (CH208) decoding display circuit, after IC6 decode output signal corresponding fields, drive common cathode LED digital tube work, it appears the corresponding point over-temperature field.

The detection circuit is adapted to units, and other train axle temperature detection occasions.

The temperature detection circuit operates through a systematic integration of components that work together to monitor and respond to changes in temperature. The temperature sensor, specifically the 3AX31, is crucial for detecting ambient temperature variations. Its linear response ensures accurate readings, which are then converted into frequency signals by the V/F converter.

The oscillator, utilizing the 555 timer IC, generates a frequency that varies with the changes in resistance of the temperature sensor. This frequency is essential for the subsequent processing stages as it provides a direct correlation between temperature and frequency, enabling precise temperature measurements.

The pulse generator, built with the CD4069 inverter, provides a consistent timing signal that drives the counting mechanism in IC3. The CD4017 counter is designed to sequentially activate its outputs based on the timing pulses, allowing for a systematic approach to monitoring multiple temperature points. Each output corresponds to a specific temperature reading, which is facilitated by the analog switches in IC4.

The phase-locked loop circuit, combined with the audio decoder IC5, serves a dual purpose: it not only processes the frequency signals but also triggers an alarm when the temperature exceeds a set threshold. The adjustable locking bandwidth allows for flexibility in the system's response to temperature fluctuations.

Finally, the decoding display circuit (IC6) provides a visual representation of the temperature status through LED indicators. This feature enhances the usability of the circuit by allowing operators to quickly assess temperature conditions at a glance.

Overall, this temperature detection circuit is designed for reliability and effectiveness in monitoring temperature in critical applications, ensuring timely alerts and facilitating preventive measures in environments where temperature control is essential. As shown in Fig ten temperature detection circuit circuit. The detection circuit by the temperature sensor, V/F converter circuit, an oscillator, circuit testing program contro l, alarm, decoded and displayed circuit. Temperature sensor 3AX31, and diode-connected form. When the ambient temperature changes, the radio - sets and resistance k linearly with temperature changes. Oscillator consists of IC1 (555) and rce, R1, C1 and other components, the oscillation frequency of f 1.44/(R1 + 2rce) C1, it rce changes linearly with temperature, then f accordingly varies in proportion to, in order to achieve temperature/frequency conversion.

If the detected 10 points, need 10 such temperature/frequency converter head. Circuit IC2 use hex inverter CD4069, where F1, F2, F3 composed of 0.2Hz trigger pulse generator, which sends a pulse count CP every 5 seconds to count circuit IC3. IC3 decimal counter/pulse distributor CD4017, under CP effect, its ten output terminal Q0 ~ Q9 successively appear high pulse.

Corresponding analog electronic switch K1 ~ K10 are sequentially turned on. IC4 using analog switches CD4066, K1 ~ K10 frequency signal outputted sequentially fed into the phase locked loop circuit having an audio decoder IC5 (567) pin (IC5 wherein the center frequency is f0 1/1.1RwC4, circuit C5 adjustable given locking bandwidth), when the temperature exceeds a certain limit the scope of the road, and with a preset center frequency f0 are the same, IC5 output low (since feet), making BG conduction, the relay J pull the trigger alarm circuit, alarm anthracene ring. At the same time, Q0 ~ Q9 high signal output of IC3 in turn fed IC6 (CH208) decoding display circuit, after IC6 decode output signal corresponding fields, drive common cathode LED digital tube work, it appears the corresponding point over-temperature field.

The detection circuit is adapted to units, and other train axle temperature detection occasions.

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713