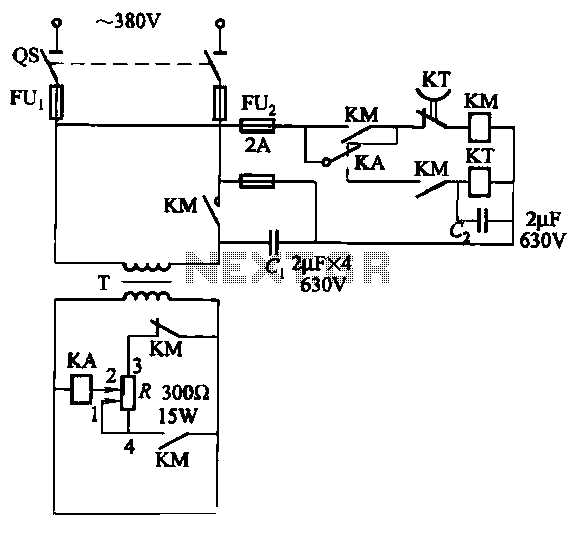

Three Relays AC arc welding machine circuit

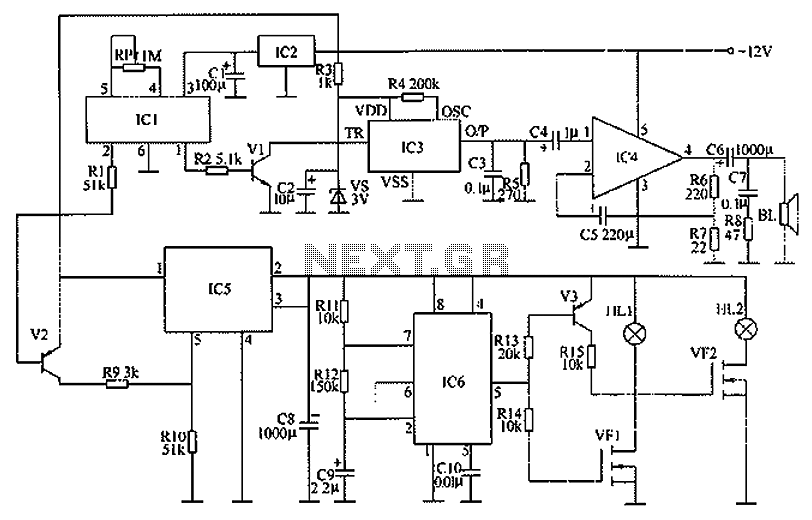

The relays in the AC arc welding machine manage the load through a three-way power circuit, as depicted in Figure 522. The selected relay type is KA, operating at 24V. Additionally, the time relay KT is of the JS7 model, with a timing range of 0.4 to 180 seconds.

The AC arc welding machine utilizes a three-way power circuit to efficiently control the welding process. The relay KA, rated at 24V, serves as a critical component in managing the load. This relay is responsible for switching the power on and off, ensuring that the welding operation is conducted safely and effectively. Its selection is crucial as it must handle the operational parameters of the welding machine, including voltage and current ratings.

The time relay KT, specifically the JS7 model, incorporates a timing mechanism that allows for precise control over the duration of the welding operation. With a timing range from 0.4 to 180 seconds, this relay can be configured to suit various welding applications, enabling adjustments based on the material being welded and the desired weld characteristics. The ability to set the time delay is essential for achieving optimal weld quality and ensuring that the welding process is completed efficiently.

In the schematic representation, the connections between the relays and the power circuit are illustrated, highlighting the flow of current and the operational sequence. The relay KA is typically connected to the primary power supply, while the time relay KT interfaces with the control circuit to initiate and terminate the welding cycle based on the preset timing parameters. Proper integration of these components is vital for the reliable operation of the AC arc welding machine, contributing to its overall performance and safety.Relays AC arc welding machine load since the three-way power circuit shown in Figure 522 relay KA selection type, 24V; time relay KT selection JS7 Ying, 0.4-180s.

The AC arc welding machine utilizes a three-way power circuit to efficiently control the welding process. The relay KA, rated at 24V, serves as a critical component in managing the load. This relay is responsible for switching the power on and off, ensuring that the welding operation is conducted safely and effectively. Its selection is crucial as it must handle the operational parameters of the welding machine, including voltage and current ratings.

The time relay KT, specifically the JS7 model, incorporates a timing mechanism that allows for precise control over the duration of the welding operation. With a timing range from 0.4 to 180 seconds, this relay can be configured to suit various welding applications, enabling adjustments based on the material being welded and the desired weld characteristics. The ability to set the time delay is essential for achieving optimal weld quality and ensuring that the welding process is completed efficiently.

In the schematic representation, the connections between the relays and the power circuit are illustrated, highlighting the flow of current and the operational sequence. The relay KA is typically connected to the primary power supply, while the time relay KT interfaces with the control circuit to initiate and terminate the welding cycle based on the preset timing parameters. Proper integration of these components is vital for the reliable operation of the AC arc welding machine, contributing to its overall performance and safety.Relays AC arc welding machine load since the three-way power circuit shown in Figure 522 relay KA selection type, 24V; time relay KT selection JS7 Ying, 0.4-180s.