Toy Motor Drivers

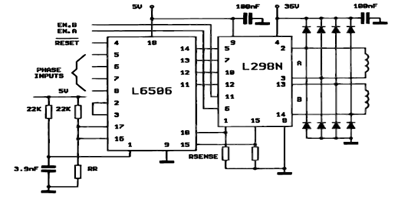

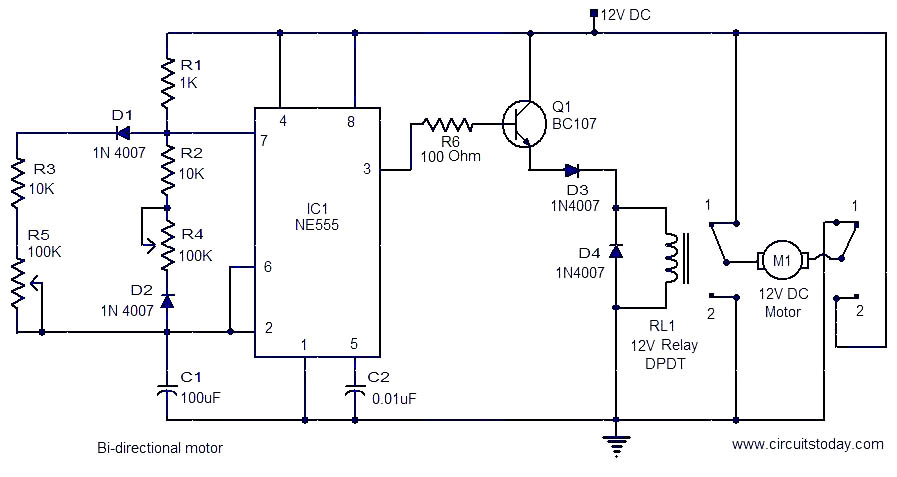

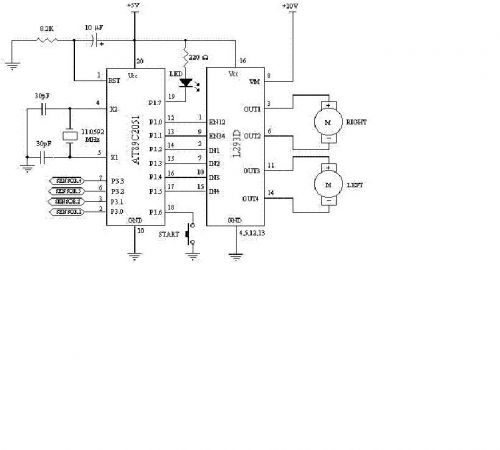

This is a reverse-engineered circuit diagram of a one-transistor circuit commonly used to drive permanent magnet DC motors in children's toys. This circuit typically employs the 625mW version of the widely used 8050 or 8550 transistor. It is important to note that there are two distinct varieties of each of these transistors, and although they may share the same part number, they are not interchangeable. One variant is a 625mW part with a higher VCEsat, while the other is a 1W part with a lower VCEsat. This can lead to confusion, as testing may be required to differentiate between them. A key feature of this circuit is that the maximum power delivered to the motor is generally limited by the VCEsat of the transistor, rather than by the HFE or base current. This design is particularly effective for children's toys that operate on a 3V or 4.5V power supply, as the natural current limiting prevents transistor burnout and extends battery life when the motor stalls. It is crucial to emphasize this point. Additionally, a ceramic transient suppression capacitor is typically soldered directly across the motor terminals, while the filter capacitor across the power supply may often be a small electrolytic capacitor instead of a ceramic disk, depending on the motor's transient suppression requirements in relation to the control circuitry.

The circuit in question is a simple yet effective design that utilizes a single transistor to control the operation of a permanent magnet DC motor. The transistor acts as a switch, allowing current to flow to the motor when the base is activated. The choice of the 8050 or 8550 transistor is critical, as these components are specifically designed to handle the power and thermal characteristics necessary for motor applications. The distinction between the 625mW and 1W variants is significant; the 625mW version is typically employed in low-power applications, ensuring that the transistor operates within safe limits under normal conditions.

The circuit's design inherently limits the current flowing through the motor when it stalls, thanks to the VCEsat characteristic of the transistor. This feature is particularly advantageous in children's toys, where unintentional stalling can occur frequently. By preventing excessive current flow, the circuit protects the transistor from damage and prolongs the life of the battery, making it a reliable solution for toy manufacturers.

Transient suppression is another crucial aspect of this circuit. The ceramic capacitor placed across the motor terminals serves to dampen voltage spikes generated by the inductive load of the motor, which can otherwise lead to electrical noise and potential damage to the circuit. The choice of a filter capacitor across the power supply can vary based on the specific requirements of the motor and control circuitry, with electrolytic capacitors often providing better performance in terms of energy storage and filtering capabilities.

In summary, this one-transistor circuit serves as an efficient and reliable means of driving permanent magnet DC motors in children's toys, with careful consideration given to component selection, current limiting, and transient suppression to ensure optimal performance and longevity.This is an actual reverse engineered circuit diagram of the one transistor circuit most commonly used to drive Permanent Magnet DC motors in childrens` toys. This type of circuit almost always uses the 625mW version of the ubiquitous 8050 or 8550 transistor. It is vital to note that there are two different varieties of each of these two transistor s, and although they are often stamped with the same part number, they are not interchangeable because one is a 625mW part with a higher VCEsat, while the other is a 1W part with a lower VCEsat. This is very confusing because you often have to run tests on these transistors to tell them apart! The important feature to note about this circuit, is that the maximum power delivered to the motor is normally designed to be limited by the VCEsat of the transistor, and almost never by the HFE or base current.

This works beutifully for childrens toys which are designed around a 3 volt or 4. 5 volt power supply, because whenever the child stalls the motor, this natural current limiting prevents burnout of the transistor and also preserves the battery life. The critical importance of the prior statement can not be overstated. Please not also that the ceramic transient suppression capacitor is always soldered directly across the motor terminals, and note that the filter capacitor across the power supply is just as often a small electrolytic instead of a ceramic disk, depending on the motor transient supression requirements of the control circuitry.

🔗 External reference

The circuit in question is a simple yet effective design that utilizes a single transistor to control the operation of a permanent magnet DC motor. The transistor acts as a switch, allowing current to flow to the motor when the base is activated. The choice of the 8050 or 8550 transistor is critical, as these components are specifically designed to handle the power and thermal characteristics necessary for motor applications. The distinction between the 625mW and 1W variants is significant; the 625mW version is typically employed in low-power applications, ensuring that the transistor operates within safe limits under normal conditions.

The circuit's design inherently limits the current flowing through the motor when it stalls, thanks to the VCEsat characteristic of the transistor. This feature is particularly advantageous in children's toys, where unintentional stalling can occur frequently. By preventing excessive current flow, the circuit protects the transistor from damage and prolongs the life of the battery, making it a reliable solution for toy manufacturers.

Transient suppression is another crucial aspect of this circuit. The ceramic capacitor placed across the motor terminals serves to dampen voltage spikes generated by the inductive load of the motor, which can otherwise lead to electrical noise and potential damage to the circuit. The choice of a filter capacitor across the power supply can vary based on the specific requirements of the motor and control circuitry, with electrolytic capacitors often providing better performance in terms of energy storage and filtering capabilities.

In summary, this one-transistor circuit serves as an efficient and reliable means of driving permanent magnet DC motors in children's toys, with careful consideration given to component selection, current limiting, and transient suppression to ensure optimal performance and longevity.This is an actual reverse engineered circuit diagram of the one transistor circuit most commonly used to drive Permanent Magnet DC motors in childrens` toys. This type of circuit almost always uses the 625mW version of the ubiquitous 8050 or 8550 transistor. It is vital to note that there are two different varieties of each of these two transistor s, and although they are often stamped with the same part number, they are not interchangeable because one is a 625mW part with a higher VCEsat, while the other is a 1W part with a lower VCEsat. This is very confusing because you often have to run tests on these transistors to tell them apart! The important feature to note about this circuit, is that the maximum power delivered to the motor is normally designed to be limited by the VCEsat of the transistor, and almost never by the HFE or base current.

This works beutifully for childrens toys which are designed around a 3 volt or 4. 5 volt power supply, because whenever the child stalls the motor, this natural current limiting prevents burnout of the transistor and also preserves the battery life. The critical importance of the prior statement can not be overstated. Please not also that the ceramic transient suppression capacitor is always soldered directly across the motor terminals, and note that the filter capacitor across the power supply is just as often a small electrolytic instead of a ceramic disk, depending on the motor transient supression requirements of the control circuitry.

🔗 External reference