Transmitter Servicing Course

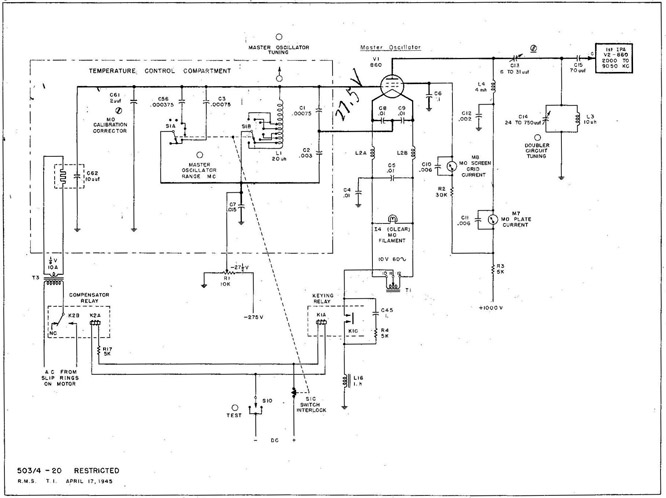

With the equipment ready for operation, the main line switch (S-831), the emergency switch (S-12), and the main line contactor contacts (K-831B) are all closed. The keying relay main contacts (K-1C) ground the center tap of the MO filament secondary of transformer T-1 to complete the DC return path to the filament and allow the MO to oscillate. Contacts K-2B connect the AC supply to the compensator transformer (T-3) to heat the compensating capacitor (C-62). This capacitor is a bi-metallic device that compensates for changes in MD circuit capacity due to the expansion of tube elements under key-down conditions. If the temperature in the compartment is below 60 °C, the thermostat (S-13) contacts are open, preventing the thermostat relay (K-20) from being energized. The heating element (R-26) is energized through the normally closed contacts (K-20B) of the thermostat relay. When the temperature in the compartment reaches 60 °C, the mercury column of the thermostat (S-13) completes the circuit to the thermostat relay coil (K-20A). If either S-13 or K-20 fails to operate, the temperature protection switch (bi-metallic Spencer Disk S-11) will turn the heating element (R-26) off and on within the limits of 71 °C and 55 °C. GENERAL CIRCUIT CONDITIONS: An electron coupled circuit, Class C, with the plate circuit always tuned to the second harmonic of the grid-screen grid circuit. Coarse tuning is achieved in 8 steps with the master oscillator range control (S-1). Switch interlock contacts S-1C break the keying circuit while S-1A and B are between steps. The MO calibration corrector capacitor (C-61) should be set half open before the transmitter is calibrated. When MO tubes or parts are changed, C-61 may be adjusted to make the MO frequency correspond to the previously calibrated settings. The bi-metallic compensating capacitor (C-62), heated by current from T-3 whenever the key is closed, compensates for changes in the MO circuit capacity due to the expansion of tube elements under operating conditions. Switches S-3B and S-3A disconnect the PA filament and connect the low power filament resistor (R-11) in series with the primary of filament transformer (T-1) to maintain 10 volts on the remaining filaments. With the antenna feed switch (S-6) in the current feed position, the antenna tuning inductance (L-13) and the antenna tuning capacitor (C-42) are connected in a series circuit. The degree of coupling between the transmitter and the antenna is adjusted with the antenna coupling control (C-41). Increased coupling should cause an increase in PA plate current (M-2). Keying relay contacts K-6C complete the DC return path to the filaments of all stages except the final PA. The PA filament return is always complete through the key thump filter (L-6 and R-8).

The described circuit operates as a sophisticated transmitter system, integrating various components to ensure optimal performance under varying conditions. The main line switch (S-831) and emergency switch (S-12) are critical for initiating and maintaining operational readiness. The keying relay (K-1C) plays a vital role in grounding the center tap of the MO filament secondary of transformer T-1, which is essential for the oscillator's functionality.

The compensator transformer (T-3) is connected to the AC supply through contacts K-2B, enabling the heating of the bi-metallic compensating capacitor (C-62). This capacitor is crucial for maintaining stability in the circuit by compensating for the thermal expansion of tube elements, thereby preventing performance degradation during key-down conditions.

Temperature regulation is ensured by the thermostat (S-13), which opens its contacts when temperatures fall below 60 °C, preventing the thermostat relay (K-20) from energizing. The heating element (R-26) is activated through the normally closed contacts (K-20B) of the thermostat relay, ensuring that the compartment remains within operational limits. The thermostat's mercury column completes the circuit to the relay coil (K-20A) when the temperature exceeds the threshold, while the bi-metallic Spencer Disk (S-11) provides an additional safety mechanism, cycling the heating element between 55 °C and 71 °C.

The circuit operates as an electron-coupled Class C system, with the plate circuit precisely tuned to the second harmonic of the grid-screen grid circuit. The master oscillator range control (S-1) allows for coarse tuning in eight distinct steps, with interlock contacts (S-1C) ensuring that the keying circuit remains disengaged during adjustments. The MO calibration corrector capacitor (C-61) is an essential component for frequency adjustments, particularly when replacing tubes or components.

The circuit also features a mechanism to maintain filament voltage through switches S-3B and S-3A, which disconnect the PA filament while connecting a low power filament resistor (R-11) to ensure consistent operation. The antenna feed switch (S-6) and associated tuning components (L-13 and C-42) facilitate effective transmission by allowing for fine-tuning of the coupling between the transmitter and the antenna. The degree of coupling can be adjusted with the antenna coupling control (C-41), which directly influences the PA plate current (M-2).

Finally, keying relay contacts (K-6C) complete the DC return path for the filaments of all stages, except for the final power amplifier (PA), which utilizes a key thump filter (L-6 and R-8) for improved performance and stability. This comprehensive integration of components ensures reliable operation of the transmitter system under a variety of conditions.With the equipment ready for operation, the main line switch (S-831), the EMERGENCY SWITCH (S-12) and the main line contactor contacts K-831B all are closed. (1) The keying relay main contacts (K-1C) ground the center tap of the MO filament secondary of T-1 to complete the DC return path to the filament and allow the MO to oscillate.

(1) Conta cts K-2B connect the AC supply to the compensator transformer (T-3) to heat the compensating capacitor (C-62). This capacitor is a bi-metallic device which compensates for the changes in MD circuit capacity due to the expansion of tube elements under key-down conditions.

(b) If the temperature in the compartment is below 60 ° C, the thermostat (S-13) contacts are open, preventing the thermostat relay (K-20) from being energized. The heating element (R-26) is energized through the normally closed contacts (K-20B) of the thermostat relay.

(c) When the temperature in the compartment reaches 60 ° C, the mercury column of the thermostat (S-13) completes the circuit to the thermostat relay coil (K-20A). (e) If either S-13 or K-20 fail to operate, the temperature protection switch (bi-metallic Spencer Disk S-11) will turn the heating element (R-26) off and on within the limits of 71 ° and 55 ° C.

2. GENERAL CIRCUIT CONDITIONS: An electron coupled circuit, Class C, with plate circuit always tuned to the second harmonic of the grid - screen grid circuit. (1) Coarse tuning in 8 steps with MASTER OSCILLATOR RANGE MC control (S-1). Switch interlock contacts S-1C break the keying circuit while S-1A and B are between steps. (b) MO CALIBRATION CORRECTOR capacitor (C-61) should be set half open before the transmitter is calibrated.

When MO tubes or parts are changed, C-61 may be adjusted to make the MO frequency correspond to the previously calibrated settings. (c) Bi-metallic compensating capacitor (C-62), heated by current from T-3 whenever the key is closed, compensates for changes in MO circuit capacity due to expansion of tube elements under operating conditions.

(a) S-3B and S-3A disconnect the PA filament and connect the low power filament resistor (R-11) in series with the primary of filament transformer (T-1) to maintain 10 volts on the remaining filaments. , (a) With the ANTENNA FEED switch (S-6) in CURRENT FEED position, the antenna tuning inductance (L-13) and the antenna tuning capacitor (C-42) are connected in a series circuit.

(c) The degree of coupling between the transmitter and the antenna is adjusted with the ANTENNA COUPLING control (C-41). Increased coupling should cause an increase in PA PLATE CURRENT (M-2). (b) Keying relay contacts K-6C complete the DC return path to the filaments of all stage`s except the final PA.

The PA filament return is always complete through the key thump filter (L-6 and R-8). 🔗 External reference

The described circuit operates as a sophisticated transmitter system, integrating various components to ensure optimal performance under varying conditions. The main line switch (S-831) and emergency switch (S-12) are critical for initiating and maintaining operational readiness. The keying relay (K-1C) plays a vital role in grounding the center tap of the MO filament secondary of transformer T-1, which is essential for the oscillator's functionality.

The compensator transformer (T-3) is connected to the AC supply through contacts K-2B, enabling the heating of the bi-metallic compensating capacitor (C-62). This capacitor is crucial for maintaining stability in the circuit by compensating for the thermal expansion of tube elements, thereby preventing performance degradation during key-down conditions.

Temperature regulation is ensured by the thermostat (S-13), which opens its contacts when temperatures fall below 60 °C, preventing the thermostat relay (K-20) from energizing. The heating element (R-26) is activated through the normally closed contacts (K-20B) of the thermostat relay, ensuring that the compartment remains within operational limits. The thermostat's mercury column completes the circuit to the relay coil (K-20A) when the temperature exceeds the threshold, while the bi-metallic Spencer Disk (S-11) provides an additional safety mechanism, cycling the heating element between 55 °C and 71 °C.

The circuit operates as an electron-coupled Class C system, with the plate circuit precisely tuned to the second harmonic of the grid-screen grid circuit. The master oscillator range control (S-1) allows for coarse tuning in eight distinct steps, with interlock contacts (S-1C) ensuring that the keying circuit remains disengaged during adjustments. The MO calibration corrector capacitor (C-61) is an essential component for frequency adjustments, particularly when replacing tubes or components.

The circuit also features a mechanism to maintain filament voltage through switches S-3B and S-3A, which disconnect the PA filament while connecting a low power filament resistor (R-11) to ensure consistent operation. The antenna feed switch (S-6) and associated tuning components (L-13 and C-42) facilitate effective transmission by allowing for fine-tuning of the coupling between the transmitter and the antenna. The degree of coupling can be adjusted with the antenna coupling control (C-41), which directly influences the PA plate current (M-2).

Finally, keying relay contacts (K-6C) complete the DC return path for the filaments of all stages, except for the final power amplifier (PA), which utilizes a key thump filter (L-6 and R-8) for improved performance and stability. This comprehensive integration of components ensures reliable operation of the transmitter system under a variety of conditions.With the equipment ready for operation, the main line switch (S-831), the EMERGENCY SWITCH (S-12) and the main line contactor contacts K-831B all are closed. (1) The keying relay main contacts (K-1C) ground the center tap of the MO filament secondary of T-1 to complete the DC return path to the filament and allow the MO to oscillate.

(1) Conta cts K-2B connect the AC supply to the compensator transformer (T-3) to heat the compensating capacitor (C-62). This capacitor is a bi-metallic device which compensates for the changes in MD circuit capacity due to the expansion of tube elements under key-down conditions.

(b) If the temperature in the compartment is below 60 ° C, the thermostat (S-13) contacts are open, preventing the thermostat relay (K-20) from being energized. The heating element (R-26) is energized through the normally closed contacts (K-20B) of the thermostat relay.

(c) When the temperature in the compartment reaches 60 ° C, the mercury column of the thermostat (S-13) completes the circuit to the thermostat relay coil (K-20A). (e) If either S-13 or K-20 fail to operate, the temperature protection switch (bi-metallic Spencer Disk S-11) will turn the heating element (R-26) off and on within the limits of 71 ° and 55 ° C.

2. GENERAL CIRCUIT CONDITIONS: An electron coupled circuit, Class C, with plate circuit always tuned to the second harmonic of the grid - screen grid circuit. (1) Coarse tuning in 8 steps with MASTER OSCILLATOR RANGE MC control (S-1). Switch interlock contacts S-1C break the keying circuit while S-1A and B are between steps. (b) MO CALIBRATION CORRECTOR capacitor (C-61) should be set half open before the transmitter is calibrated.

When MO tubes or parts are changed, C-61 may be adjusted to make the MO frequency correspond to the previously calibrated settings. (c) Bi-metallic compensating capacitor (C-62), heated by current from T-3 whenever the key is closed, compensates for changes in MO circuit capacity due to expansion of tube elements under operating conditions.

(a) S-3B and S-3A disconnect the PA filament and connect the low power filament resistor (R-11) in series with the primary of filament transformer (T-1) to maintain 10 volts on the remaining filaments. , (a) With the ANTENNA FEED switch (S-6) in CURRENT FEED position, the antenna tuning inductance (L-13) and the antenna tuning capacitor (C-42) are connected in a series circuit.

(c) The degree of coupling between the transmitter and the antenna is adjusted with the ANTENNA COUPLING control (C-41). Increased coupling should cause an increase in PA PLATE CURRENT (M-2). (b) Keying relay contacts K-6C complete the DC return path to the filaments of all stage`s except the final PA.

The PA filament return is always complete through the key thump filter (L-6 and R-8). 🔗 External reference