ultrasonic cleaning transducers series parallel

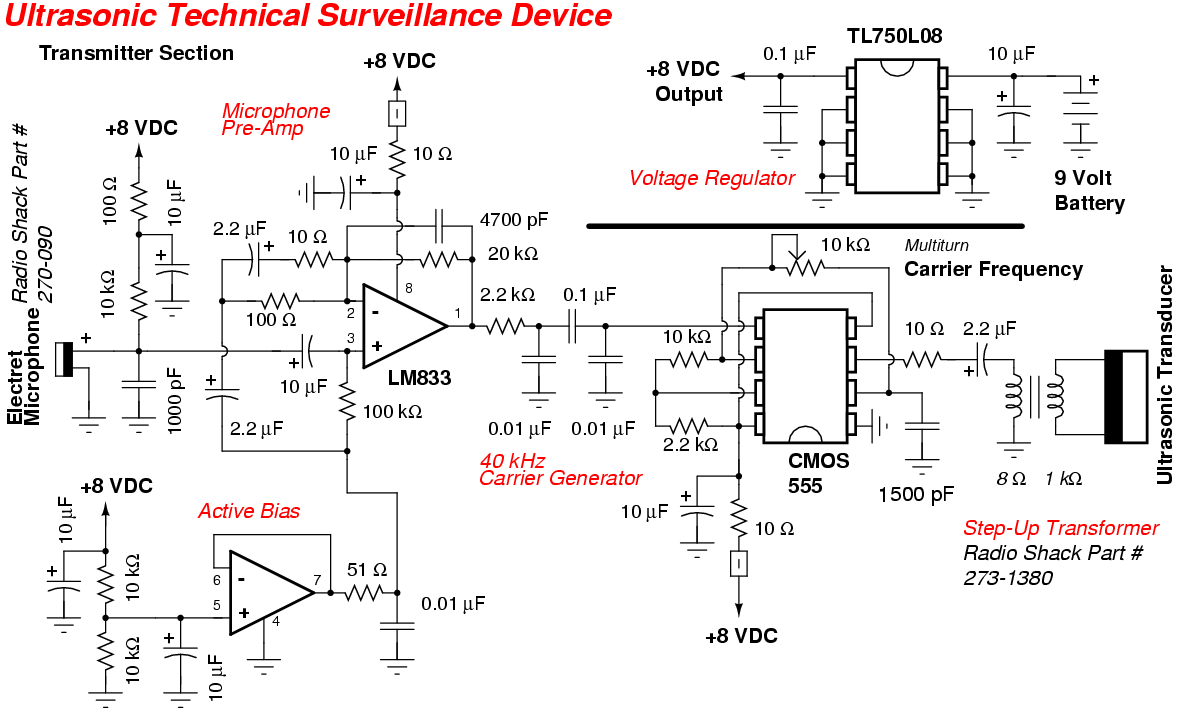

A small ultrasonic cleaning device currently operates with one 50W transducer. There are plans to construct another device using two 20W transducers, and the best configuration for wiring them—either in series or in parallel—is being considered. The circuit designs are experimental; although they function in simulations, component values may require adjustments, and additional components might be necessary during actual construction. Safety precautions must be observed when dealing with circuits involving mains voltage or electrostatic-sensitive components. Precise positioning of the transducers is essential to prevent cancellation effects. The impedance of the 20W unit compared to the 50W unit is a critical factor for impedance matching. Wiring in series is considered a likely option, as the impedance for two 20W transducers in parallel would be 15 Ohms, which is closer to the standard transducer impedance of 20 Ohms compared to the 60 Ohms resulting from a series configuration.

The ultrasonic cleaning device operates by converting electrical energy into high-frequency sound waves through the transducer(s). The existing design utilizes a single 50W transducer, which is capable of generating the necessary ultrasonic waves for effective cleaning. The proposed design modification involves the integration of two 20W transducers, which may enhance cleaning efficiency if configured correctly.

When considering the configuration of the transducers, the impedance matching is vital for optimal performance. In parallel, two 20W transducers would yield an equivalent impedance of 15 Ohms, which aligns more closely with the typical 20 Ohm impedance of a standard transducer. This configuration may provide better power distribution and efficiency, allowing for effective operation without overloading the power source.

Conversely, wiring the transducers in series would result in a combined impedance of 60 Ohms, which could lead to underperformance due to insufficient power delivery to each transducer. The series configuration may also require adjustments to the driving circuit to accommodate the higher impedance, potentially complicating the design.

In addition to impedance considerations, the physical placement of the transducers is crucial. Precise alignment is necessary to ensure that the ultrasonic waves produced do not interfere destructively, which could diminish the cleaning effectiveness. This requires careful measurement and adjustment during assembly.

Furthermore, safety precautions are paramount when working with circuits that involve mains voltage. Proper insulation, circuit breakers, and other protective measures should be implemented to prevent electric shock or equipment damage. Additionally, attention must be paid to components sensitive to electrostatic discharge, ensuring that they are handled in a controlled environment to prevent failure.

In summary, the choice of series or parallel configuration for the transducers should be guided by impedance matching principles, operational efficiency, and safety considerations. Adjustments to component values and circuit design may be necessary during the construction phase to achieve the desired performance of the ultrasonic cleaning device.A small ultrasonic cleaning device and it runs 1 x 50W transducer at the moment. I am going to build another that uses two 20W transducers and was just wondering what the best configuration is, to wire them in series or in parallel My circuit designs should be regarded as experimental. Although they work in simulation, their component values may need altering or additional components may be necessary when the circuits are built. Due safety precautions should be taken with any circuit involving mains voltage or electrostatic-sensitive components. You are going to have to position your transducers at very precise distances from each other to avoid them canceling one another out.

It depends on the impedance of the 20watt unit compared to the 50watt unit, you do need to impedance match, I`m thinking series is probably the way to go, With the Ohms at 30 per 20W parallel would make it 15 Ohms which is probably closer to the 20 Ohms of the standard transducer as opposed to series that would make it 60 Ohms 🔗 External reference

The ultrasonic cleaning device operates by converting electrical energy into high-frequency sound waves through the transducer(s). The existing design utilizes a single 50W transducer, which is capable of generating the necessary ultrasonic waves for effective cleaning. The proposed design modification involves the integration of two 20W transducers, which may enhance cleaning efficiency if configured correctly.

When considering the configuration of the transducers, the impedance matching is vital for optimal performance. In parallel, two 20W transducers would yield an equivalent impedance of 15 Ohms, which aligns more closely with the typical 20 Ohm impedance of a standard transducer. This configuration may provide better power distribution and efficiency, allowing for effective operation without overloading the power source.

Conversely, wiring the transducers in series would result in a combined impedance of 60 Ohms, which could lead to underperformance due to insufficient power delivery to each transducer. The series configuration may also require adjustments to the driving circuit to accommodate the higher impedance, potentially complicating the design.

In addition to impedance considerations, the physical placement of the transducers is crucial. Precise alignment is necessary to ensure that the ultrasonic waves produced do not interfere destructively, which could diminish the cleaning effectiveness. This requires careful measurement and adjustment during assembly.

Furthermore, safety precautions are paramount when working with circuits that involve mains voltage. Proper insulation, circuit breakers, and other protective measures should be implemented to prevent electric shock or equipment damage. Additionally, attention must be paid to components sensitive to electrostatic discharge, ensuring that they are handled in a controlled environment to prevent failure.

In summary, the choice of series or parallel configuration for the transducers should be guided by impedance matching principles, operational efficiency, and safety considerations. Adjustments to component values and circuit design may be necessary during the construction phase to achieve the desired performance of the ultrasonic cleaning device.A small ultrasonic cleaning device and it runs 1 x 50W transducer at the moment. I am going to build another that uses two 20W transducers and was just wondering what the best configuration is, to wire them in series or in parallel My circuit designs should be regarded as experimental. Although they work in simulation, their component values may need altering or additional components may be necessary when the circuits are built. Due safety precautions should be taken with any circuit involving mains voltage or electrostatic-sensitive components. You are going to have to position your transducers at very precise distances from each other to avoid them canceling one another out.

It depends on the impedance of the 20watt unit compared to the 50watt unit, you do need to impedance match, I`m thinking series is probably the way to go, With the Ohms at 30 per 20W parallel would make it 15 Ohms which is probably closer to the 20 Ohms of the standard transducer as opposed to series that would make it 60 Ohms 🔗 External reference