Unipolar Stepper Motor Driver

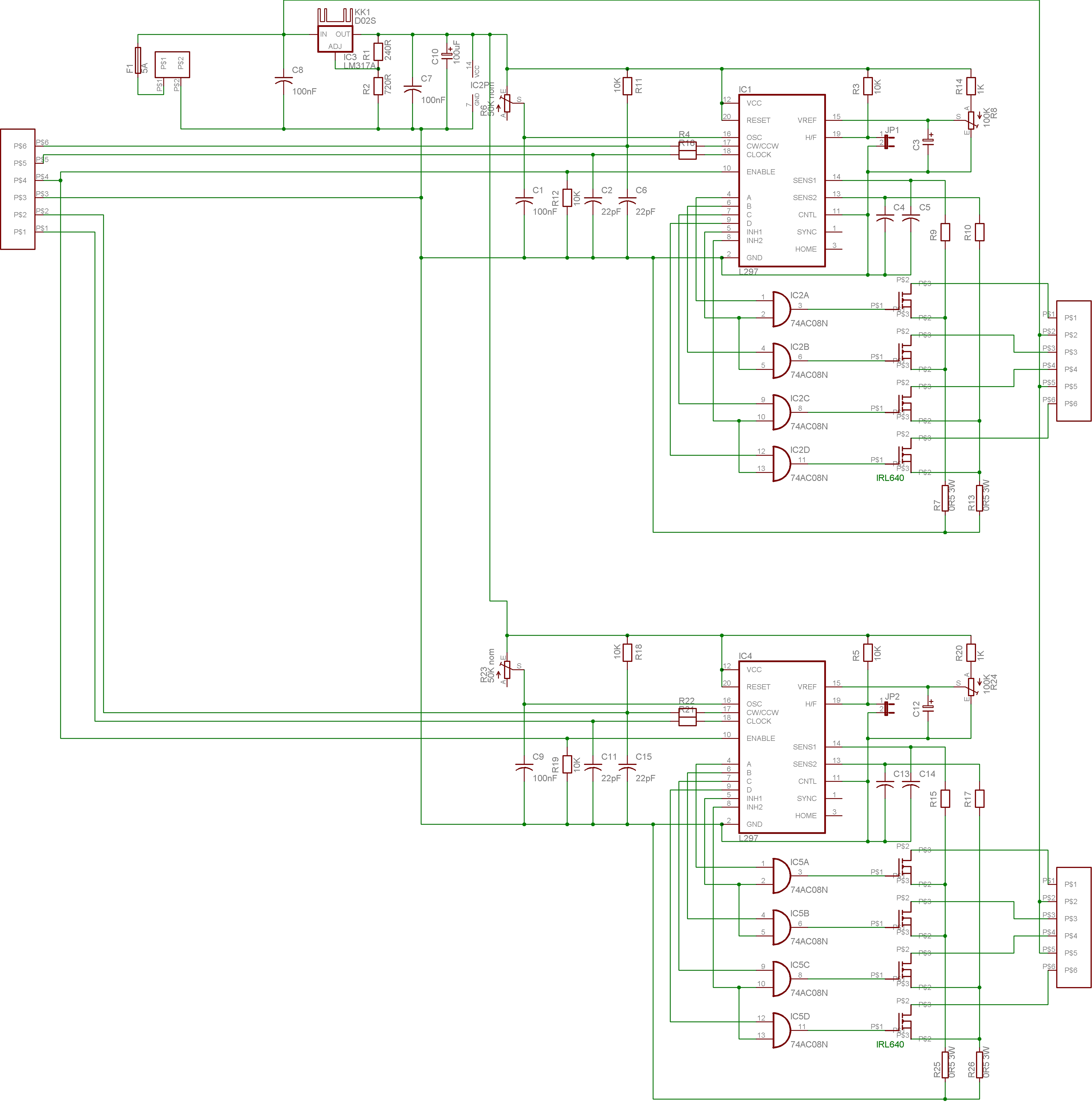

The objective of this project is to create a stepper motor driver for 2-phase unipolar stepper motors that incorporates built-in current control. This driver is intended for a CNC milling machine currently in the planning stage. Essential components must be integrated to provide a complete driver solution. Current supplied to the motor coils needs to be limited to prevent overheating and damage. A chopper circuit is a suitable option for this purpose. An intelligent controller is also necessary to ensure the correct number of steps for the desired travel distance. While many CNC projects utilize a PC parallel port for control, the intention is to develop a stand-alone driver that can serve multiple applications. Ideally, the system will include Ethernet control to enable remote operation of the CNC machine from a comfortable location, eliminating the need for a dedicated control PC. The design is centered around the L297 driver IC, which translates clock and direction inputs into the appropriate output sequence for driving the stepper motor and features current limiting capabilities. Additional logic and driver circuitry will be implemented to manage the motor coils. Each motor driver operates independently, controlled by its own clock and direction signals, with separate current limiting settings to prevent interference. The final design is a synthesis of several common designs found online, informed by various searches and personal experiments. A valuable resource for understanding stepper motors is the work by Jones on Stepping Motors. The selection of FETs is crucial, as they must handle full current switching for each motor coil and withstand the inductive EMF spikes generated, which can damage the FETs. Some designs incorporate diodes for spike control, but experiments indicated that this approach can lead to increased heat generation and other issues. Therefore, the chosen circuit relies on FETs rated sufficiently high to manage these spikes without the need for diodes. The specification is approximately four times the supply voltage, although a more precise calculation may be beneficial. Additionally, the logic level used to activate the FETs, referred to as Vgs (the voltage across the gate-source junction), must be considered. In practice, Vgs is calculated as Vcc minus Vsense, where Vsense is the voltage across the sense resistor. This voltage must be controlled and limited, with the FET specified to operate within the remaining voltage. The L297 device regulates the sense resistor voltage through its current limiting circuitry. When Vsense reaches the reference voltage at the L297 Vref pin, the inhibit output lines deactivate, switching off the FETs and reducing Vsense. This cycle results in an oscillating voltage across the sense resistor, known as chopper action. Measurement of this "chopped" voltage typically yields a value of approximately two-thirds of Vref, but for calculation purposes, Vref itself is preferred. Thus, the formula is revised to Vgs = Vcc - Vref. With Vref set between 0-1V and a supply voltage of 5V for the logic, Vgs calculates to 4V. It is essential to consult the datasheet of the selected FET to examine the Vgs versus Ids graph, ensuring that at Vgs = 4V, the graph is not in the linear region and is fully switched on.

The stepper motor driver circuit is designed to efficiently manage the operation of 2-phase unipolar stepper motors by utilizing the L297 driver IC. The L297 is responsible for converting input signals into the appropriate sequence required to energize the motor coils, facilitating precise control over motor positioning. The implementation of current limiting is achieved through a feedback mechanism that monitors the voltage across a sense resistor. This resistor is strategically placed in series with the motor coils to provide real-time feedback of the current flowing through them.

The chopper control mechanism is a crucial aspect of this design, allowing for the dynamic adjustment of the current supplied to the motor coils. When the sensed current exceeds the predetermined threshold, the L297 interrupts the drive signal to the FETs, effectively reducing the current and preventing overheating. This feedback loop operates at a high frequency, ensuring that the current remains within safe operating limits while maintaining optimal performance.

Ethernet control integration enables remote operation of the CNC milling machine, allowing users to send commands and monitor the machine's status from a distance. This is achieved through a microcontroller that interfaces with the L297 and manages communication over the Ethernet network. The controller is programmed to interpret incoming commands, translate them into appropriate clock and direction signals, and relay these signals to the L297, ensuring accurate stepper motor operation.

The choice of FETs is critical to the success of this driver circuit. High-performance FETs are selected based on their ability to handle the required current without overheating and their capacity to withstand inductive spikes generated during motor operation. The absence of diodes in the circuit design minimizes additional heat generation and enhances efficiency. Careful attention to the FET specifications ensures reliable operation across a range of conditions.

Overall, this stepper motor driver design combines advanced current control techniques with robust logic and communication capabilities, resulting in a versatile solution suitable for a variety of applications, including CNC milling and other automation tasks.The purpose of this project was to develop a stepper motor driver for 2-phase unipolar stepper motors that has built in current control. The eventual target project for this driver is for my CNC milling machine that I am currently planning out.

This needs a few elements that are combined to provide a full driver. Once this is established the curre nt being supplied to the motor coils needs to be limitted in some way to stop melting anything. The obvious option here is to use a chopper circuit. Finally an intelligent controller is required to provide the correct number of steps for a required distance of travel. Many simply use a PC parallel port for this on CNC projects but I want this to be more of a stand-alone driver that can be used for other things.

Ideally I will include ethernet control so that I can run the CNC machine remotely from the comfort of my living room instead of the cold garage and negates the need for a dedicated control PC. The device is based around an L297 driver IC that performs the translation step (ie takes clock and direction input and generates the correct output sequence for driving the stepper) and has current limitting abilities.

Additional logic and driver circuitry is then added to drive the motor coils. Each motor driver is fully independant of the other drives and is controlled with its own clock and direction signals, has a seperate current limitter setting and should not interfere with each other. In reaching this final solution I went through many designs, some of my own, some through various searches on the net.

The final design is a combination of a few of the most common designs that can be found on the internet. One useful site I used is there are some good designs of stepper drivers and also a bulletin board where people share experiences and the owner gives great help.

A good resource for describing stepper motors is Jones on Stepping Motors The FETs must be chosen to allow the switching of each coil in the motor at full current. They must also be able to cope with the inductive EMF spike generated by the motor that could otherwise destroy the FET.

Some circuits show diodes being used to help control this spike and protect the FET, however in my experiments they caused more problems than they solved and generated a lot of heat. My circuit solution is simply to use FETs that are rated high enough to cope with this spike without the diode.

Approximetly I have spec`d this as around 4 times the supply voltage, however there may be a better calculation to work out the exact requirement. The next thing to consider is the logic level that will be used to turn the FETs on/off, referred to as Vgs (voltage across the gate-source junction).

In practice Vgs = Vcc - Vsense. ie The voltage across the FET gate is the supply voltage less the voltage across the sense resistor. The voltage across the sense resistor must therefore be controlled/limitted and the FET spec`d to work with `what is left`. The sense resistor voltage is limitted by the L297 device by means of the current limitting circuitry.

When Vsense (voltage across the sense resistor) reaches the reference voltage into the L297 Vref pin the inhibit output lines drop, in turn switching off the FETs and dropping Vsense. This sequence repeats giving an oscillating voltage across the sense resistor, this is known as the chopper action.

In practise when measuring this `chopped` voltage the reading is approx 2/3 of Vref, but for our calculations (giving us some VAT) it is best to use Vref itself in the calculations. So re-writing the previous formula: Vgs = Vcc - Vref. We set Vref between 0-1V and use a supply voltage of 5V for the logic. So Vgs = 5 - 1 = 4V. Now we need to refer to the datasheet of our FET and look at the Vgs vs Ids graph and ensure that when Vgs=4V the graph is not in its linear section (ie it has levelled out) and is therefore fully switched on.

This will give us 🔗 External reference

The stepper motor driver circuit is designed to efficiently manage the operation of 2-phase unipolar stepper motors by utilizing the L297 driver IC. The L297 is responsible for converting input signals into the appropriate sequence required to energize the motor coils, facilitating precise control over motor positioning. The implementation of current limiting is achieved through a feedback mechanism that monitors the voltage across a sense resistor. This resistor is strategically placed in series with the motor coils to provide real-time feedback of the current flowing through them.

The chopper control mechanism is a crucial aspect of this design, allowing for the dynamic adjustment of the current supplied to the motor coils. When the sensed current exceeds the predetermined threshold, the L297 interrupts the drive signal to the FETs, effectively reducing the current and preventing overheating. This feedback loop operates at a high frequency, ensuring that the current remains within safe operating limits while maintaining optimal performance.

Ethernet control integration enables remote operation of the CNC milling machine, allowing users to send commands and monitor the machine's status from a distance. This is achieved through a microcontroller that interfaces with the L297 and manages communication over the Ethernet network. The controller is programmed to interpret incoming commands, translate them into appropriate clock and direction signals, and relay these signals to the L297, ensuring accurate stepper motor operation.

The choice of FETs is critical to the success of this driver circuit. High-performance FETs are selected based on their ability to handle the required current without overheating and their capacity to withstand inductive spikes generated during motor operation. The absence of diodes in the circuit design minimizes additional heat generation and enhances efficiency. Careful attention to the FET specifications ensures reliable operation across a range of conditions.

Overall, this stepper motor driver design combines advanced current control techniques with robust logic and communication capabilities, resulting in a versatile solution suitable for a variety of applications, including CNC milling and other automation tasks.The purpose of this project was to develop a stepper motor driver for 2-phase unipolar stepper motors that has built in current control. The eventual target project for this driver is for my CNC milling machine that I am currently planning out.

This needs a few elements that are combined to provide a full driver. Once this is established the curre nt being supplied to the motor coils needs to be limitted in some way to stop melting anything. The obvious option here is to use a chopper circuit. Finally an intelligent controller is required to provide the correct number of steps for a required distance of travel. Many simply use a PC parallel port for this on CNC projects but I want this to be more of a stand-alone driver that can be used for other things.

Ideally I will include ethernet control so that I can run the CNC machine remotely from the comfort of my living room instead of the cold garage and negates the need for a dedicated control PC. The device is based around an L297 driver IC that performs the translation step (ie takes clock and direction input and generates the correct output sequence for driving the stepper) and has current limitting abilities.

Additional logic and driver circuitry is then added to drive the motor coils. Each motor driver is fully independant of the other drives and is controlled with its own clock and direction signals, has a seperate current limitter setting and should not interfere with each other. In reaching this final solution I went through many designs, some of my own, some through various searches on the net.

The final design is a combination of a few of the most common designs that can be found on the internet. One useful site I used is there are some good designs of stepper drivers and also a bulletin board where people share experiences and the owner gives great help.

A good resource for describing stepper motors is Jones on Stepping Motors The FETs must be chosen to allow the switching of each coil in the motor at full current. They must also be able to cope with the inductive EMF spike generated by the motor that could otherwise destroy the FET.

Some circuits show diodes being used to help control this spike and protect the FET, however in my experiments they caused more problems than they solved and generated a lot of heat. My circuit solution is simply to use FETs that are rated high enough to cope with this spike without the diode.

Approximetly I have spec`d this as around 4 times the supply voltage, however there may be a better calculation to work out the exact requirement. The next thing to consider is the logic level that will be used to turn the FETs on/off, referred to as Vgs (voltage across the gate-source junction).

In practice Vgs = Vcc - Vsense. ie The voltage across the FET gate is the supply voltage less the voltage across the sense resistor. The voltage across the sense resistor must therefore be controlled/limitted and the FET spec`d to work with `what is left`. The sense resistor voltage is limitted by the L297 device by means of the current limitting circuitry.

When Vsense (voltage across the sense resistor) reaches the reference voltage into the L297 Vref pin the inhibit output lines drop, in turn switching off the FETs and dropping Vsense. This sequence repeats giving an oscillating voltage across the sense resistor, this is known as the chopper action.

In practise when measuring this `chopped` voltage the reading is approx 2/3 of Vref, but for our calculations (giving us some VAT) it is best to use Vref itself in the calculations. So re-writing the previous formula: Vgs = Vcc - Vref. We set Vref between 0-1V and use a supply voltage of 5V for the logic. So Vgs = 5 - 1 = 4V. Now we need to refer to the datasheet of our FET and look at the Vgs vs Ids graph and ensure that when Vgs=4V the graph is not in its linear section (ie it has levelled out) and is therefore fully switched on.

This will give us 🔗 External reference