usb pow

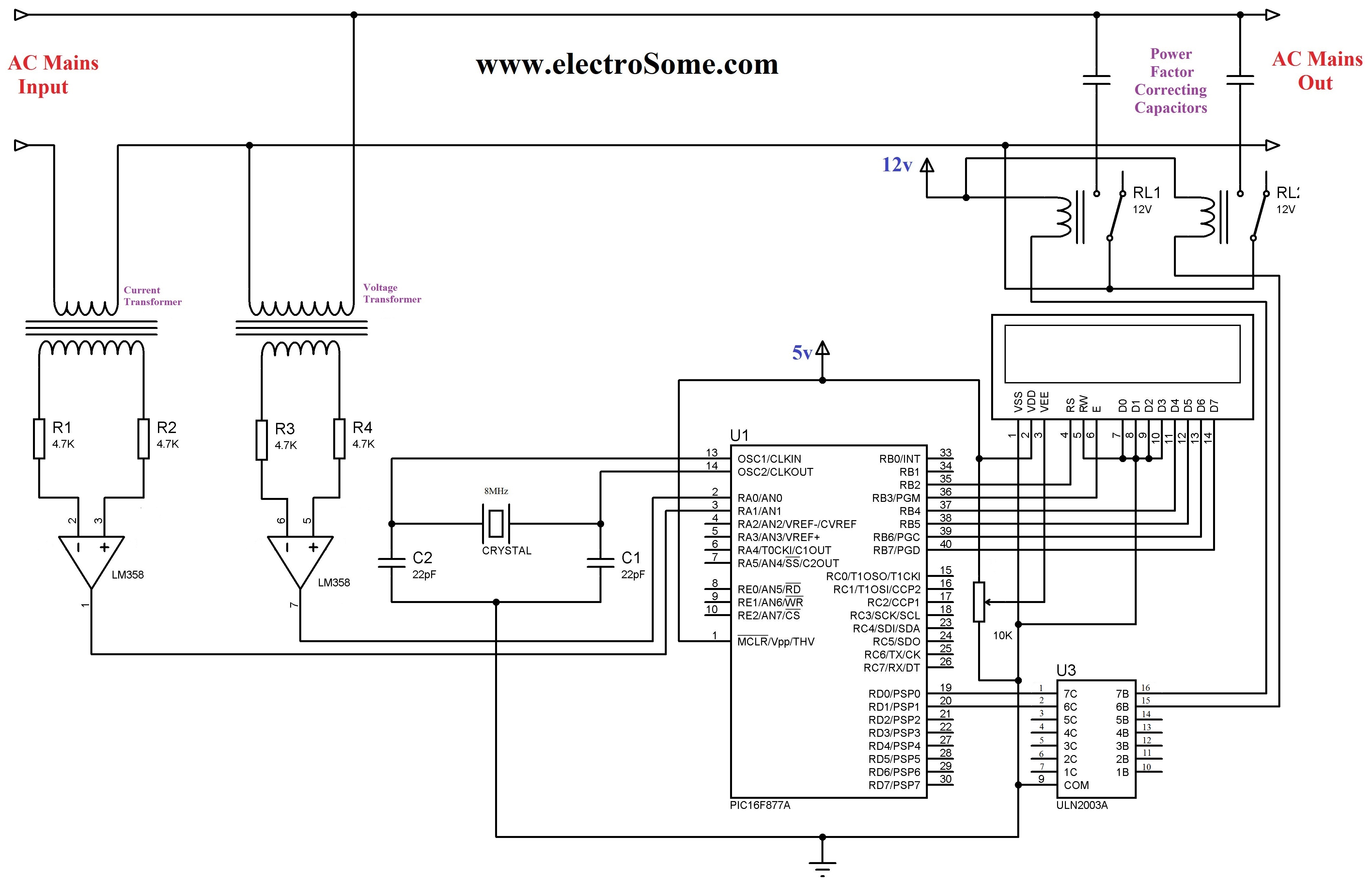

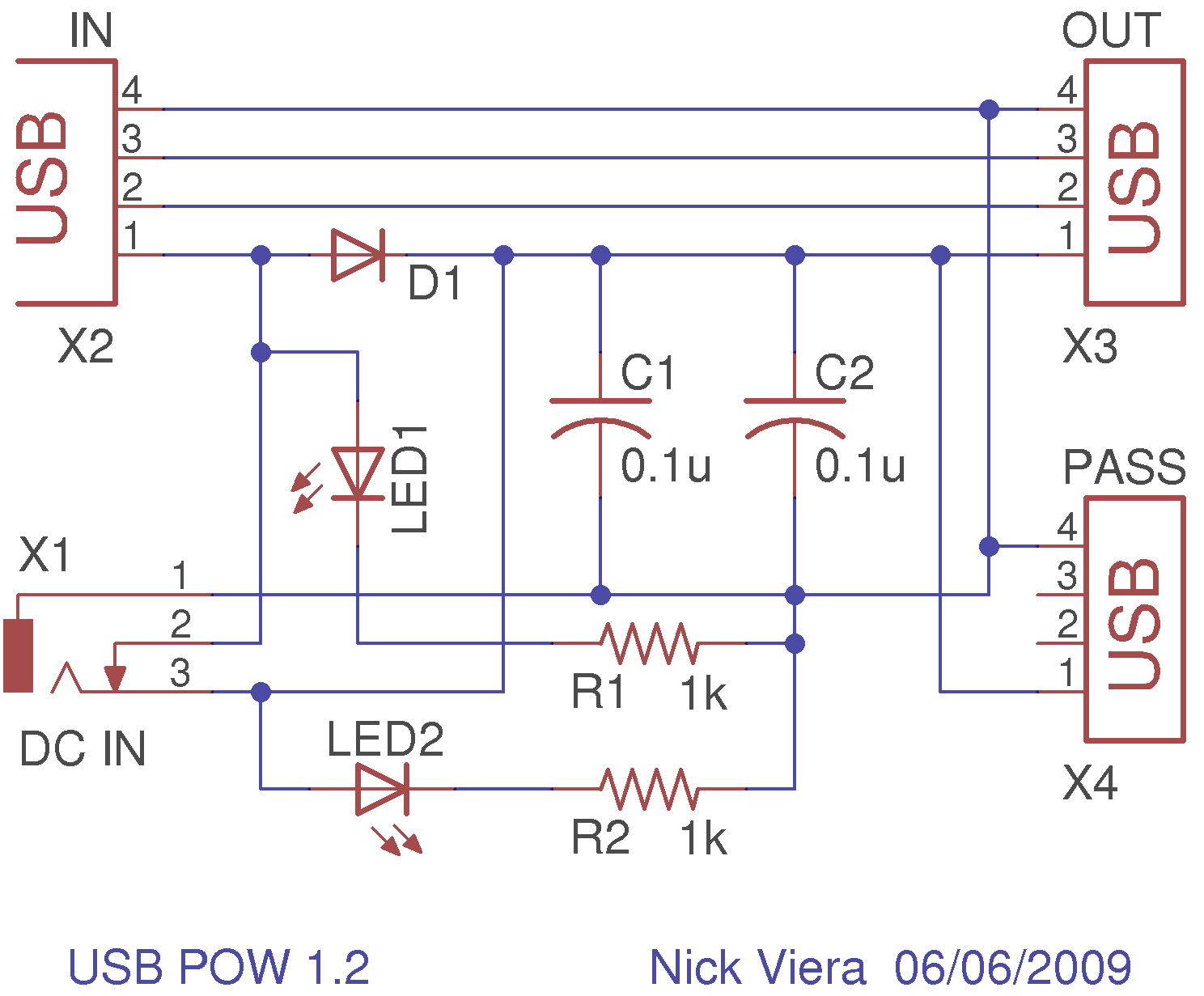

The USB standard limits the current consumption of all USB devices to either 100mA or 500mA, depending on the specifications of the USB hub or host controller (e.g., a computer) supplying the power. Ideally, no USB device should draw more than 500mA from a USB port. However, this is not always the case due to two primary issues. The first issue is high "inrush" current during the startup of certain USB devices. For instance, a USB hard drive attempting to spin up can temporarily draw significantly more than 500mA from its USB port. The second issue arises when high-power USB devices are connected through long USB cables or active USB repeaters, which can lead to substantial voltage drops along the cable length, resulting in some USB devices being underpowered and failing to operate reliably or at all. Additionally, some USB host controllers are known to be "weak" and unable to deliver the full power required by the USB standard. Weak host controllers are commonly found in certain laptops and peripherals with integrated USB hubs, such as computer monitors and printers. USB POW is designed to enable high-powered USB devices to function reliably with underpowered host controllers and hubs. The schematics for USB POW are provided below, with the latest version being revision 1.3. Older schematics are included for historical reference but are not guaranteed to operate correctly. The printed circuit board for USB POW is a standard 2-layer board. Board revision 1.3 allows USB POW to be used with DC power supplies that have a tip = positive and ring = negative polarity, while the previous revision relies on the less common polarity of tip = negative and ring = positive for proper operation.

The USB POW circuit is designed to address the limitations imposed by the USB standard regarding current supply and voltage stability. It incorporates features to manage inrush current, thus preventing excessive current draw during the startup phase of connected devices. This is particularly important for devices such as external hard drives, which may require a surge of current to initiate their operation.

The PCB layout is optimized for minimal resistance and inductance, which helps mitigate voltage drops across long cable runs. The use of quality components, including low-resistance traces and suitable capacitors, ensures that voltage levels remain stable, even under high load conditions. The design also includes protection mechanisms to safeguard both the USB devices and the host controller from potential damage due to overcurrent situations.

USB POW’s compatibility with various DC power supply configurations enhances its versatility, allowing it to be integrated into different systems without the need for extensive modifications. This adaptability makes it suitable for use in a range of applications, from consumer electronics to industrial equipment. The detailed schematics provided for revision 1.3 highlight the circuit's functionality and layout, serving as a guide for implementation and troubleshooting.

In summary, USB POW is a robust solution for ensuring reliable operation of high-power USB devices, particularly in scenarios where host controllers may be inadequate in providing the necessary power. The thoughtful design and engineering principles employed in the USB POW circuit make it an essential component for enhancing USB device performance and reliability in various applications.The USB standard restricts the current consumption of all USB devices to either 100mA or 500mA depending on the specifics of the USB hub and/or host controller (i. e. computer) that is supplying the power. Ideally, no USB device should ever pull more than 500mA of current from a USB port. In reality this is not always the case. There are two main issues that can cause a USB device to attempt to exceed the 100mA or 500mA limit. The first is high "inrush" current during the startup of some USB devices. For example, a USB hard drive trying to spin up can temporarily attempt to pull much more than 500mA from its USB port. The second issue is the connection of high-power USB devices through long USB cables or active USB "repeaters" (really really long USB cables.

) In both cases, the large voltage drop that can occur over the length of such USB cables will cause some USB devices to be under-powered and fail to work reliably. or at all. Lastly, some USB host controllers are notorious for being "weak" and unable to provide the full power required by the USB standard.

Weak host controllers are found in some laptops and peripherals with integrated USB hubs (such as computer monitors, printers, etc. ) USB POW is also ideal for allowing high-powered USB devices to work reliably with under-powered host controllers and hubs.

Below are the schematics for USB POW. The latest schematic is revision 1. 3. Older schematics are also shown, but only for historical information. They are not guaranteed to work correctly. The printed circuit board for USB POW is a standard 2-layer board. Board revision 1. 3 allows USB POW to be used with DC power supplies whose polarity is tip = positive, ring = negative. Board revision relies on the less common polarity tip = negative, ring = positive for proper operation.

Use the following links to: 🔗 External reference

The USB POW circuit is designed to address the limitations imposed by the USB standard regarding current supply and voltage stability. It incorporates features to manage inrush current, thus preventing excessive current draw during the startup phase of connected devices. This is particularly important for devices such as external hard drives, which may require a surge of current to initiate their operation.

The PCB layout is optimized for minimal resistance and inductance, which helps mitigate voltage drops across long cable runs. The use of quality components, including low-resistance traces and suitable capacitors, ensures that voltage levels remain stable, even under high load conditions. The design also includes protection mechanisms to safeguard both the USB devices and the host controller from potential damage due to overcurrent situations.

USB POW’s compatibility with various DC power supply configurations enhances its versatility, allowing it to be integrated into different systems without the need for extensive modifications. This adaptability makes it suitable for use in a range of applications, from consumer electronics to industrial equipment. The detailed schematics provided for revision 1.3 highlight the circuit's functionality and layout, serving as a guide for implementation and troubleshooting.

In summary, USB POW is a robust solution for ensuring reliable operation of high-power USB devices, particularly in scenarios where host controllers may be inadequate in providing the necessary power. The thoughtful design and engineering principles employed in the USB POW circuit make it an essential component for enhancing USB device performance and reliability in various applications.The USB standard restricts the current consumption of all USB devices to either 100mA or 500mA depending on the specifics of the USB hub and/or host controller (i. e. computer) that is supplying the power. Ideally, no USB device should ever pull more than 500mA of current from a USB port. In reality this is not always the case. There are two main issues that can cause a USB device to attempt to exceed the 100mA or 500mA limit. The first is high "inrush" current during the startup of some USB devices. For example, a USB hard drive trying to spin up can temporarily attempt to pull much more than 500mA from its USB port. The second issue is the connection of high-power USB devices through long USB cables or active USB "repeaters" (really really long USB cables.

) In both cases, the large voltage drop that can occur over the length of such USB cables will cause some USB devices to be under-powered and fail to work reliably. or at all. Lastly, some USB host controllers are notorious for being "weak" and unable to provide the full power required by the USB standard.

Weak host controllers are found in some laptops and peripherals with integrated USB hubs (such as computer monitors, printers, etc. ) USB POW is also ideal for allowing high-powered USB devices to work reliably with under-powered host controllers and hubs.

Below are the schematics for USB POW. The latest schematic is revision 1. 3. Older schematics are also shown, but only for historical information. They are not guaranteed to work correctly. The printed circuit board for USB POW is a standard 2-layer board. Board revision 1. 3 allows USB POW to be used with DC power supplies whose polarity is tip = positive, ring = negative. Board revision relies on the less common polarity tip = negative, ring = positive for proper operation.

Use the following links to: 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713