Vacuum tube tesla coil (VTTC) using Russian GI-30

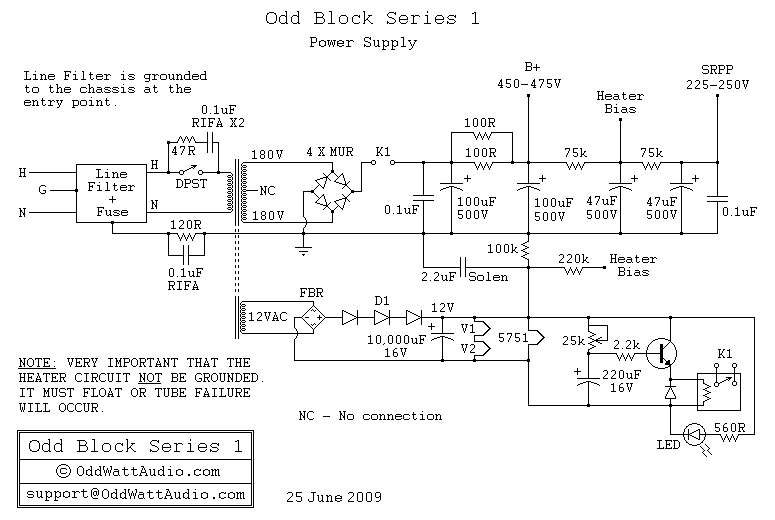

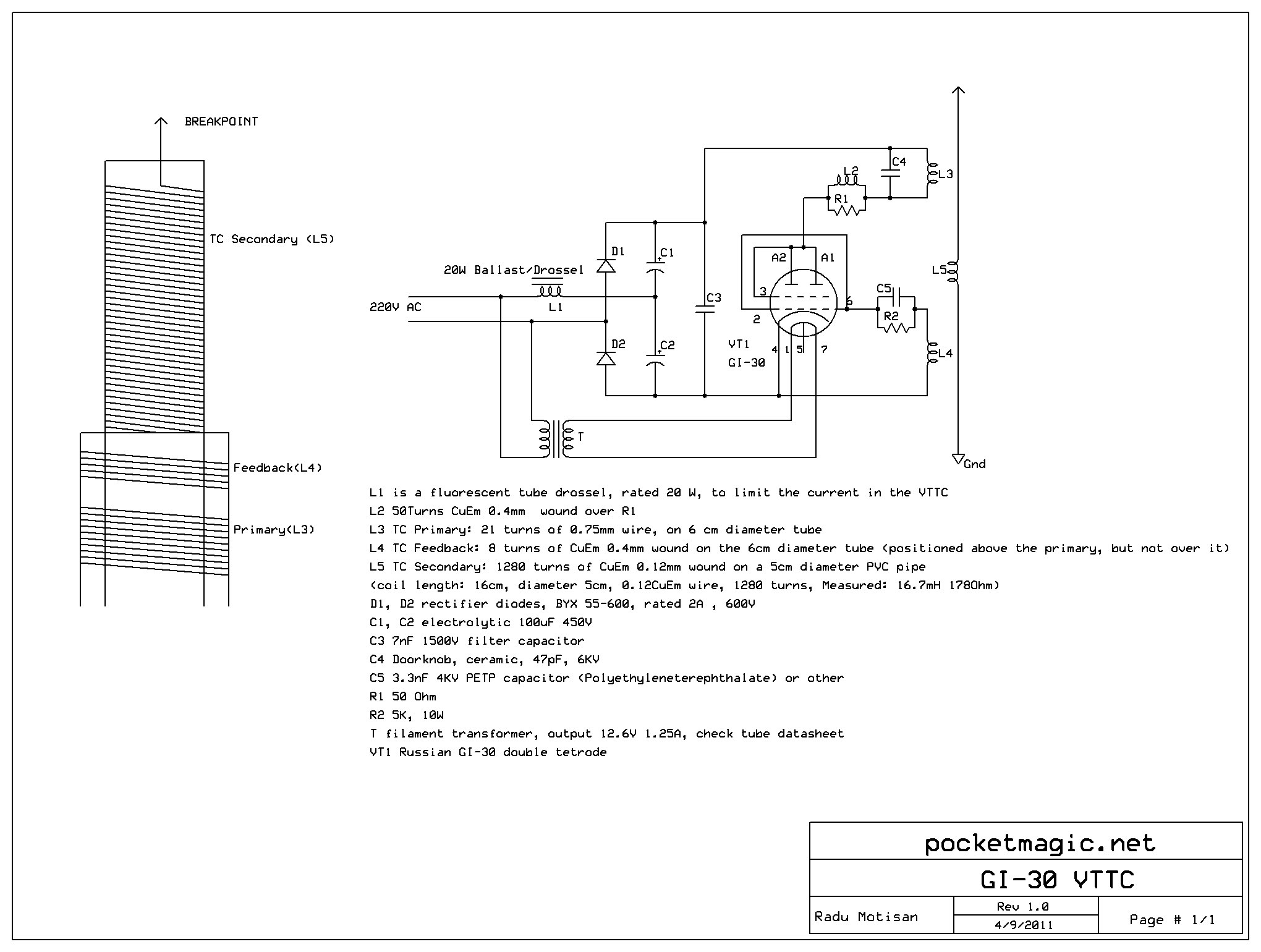

This setup is compact and operates offline directly from a 220V source, utilizing a voltage doubler to elevate the plate voltage to 560V DC. The circuit consists of a simple Armstrong oscillator, employing the feedback coil L4. The design aims for compactness and incorporates a 220V ATX PC supply connector, a switch to power the tube, and another switch to select between under-nominal and nominal filament voltages of 12.6V. It is crucial that the voltage remains at 12.6V when the tube is connected. Various combinations of secondary and primary coils were tested, adjusting the number of turns and coil diameters, along with capacitor values, to optimize spark generation, RF emission, and power levels. This process was time-consuming but essential for the construction of the VTTC. The final coil design proved to be the most effective and compact compared to previous iterations. Manual winding was required, which added to the time investment, but ultimately resulted in a successful application. The final assembly necessitated repositioning the electrolytic capacitors and covering them with wood to create sufficient space for the coil, oscillator, and feedback capacitors on the same base.

This circuit design is based on a voltage doubler configuration that converts the standard 220V AC supply into a higher DC voltage suitable for the operation of a Vacuum Tube Tesla Coil (VTTC). The voltage doubler typically consists of two diodes and two capacitors arranged in a configuration that allows the peak voltage to be effectively doubled, thus achieving the necessary 560V DC for the plate voltage.

The Armstrong oscillator circuit is characterized by its simplicity and effectiveness in generating high-voltage oscillations. The feedback coil, designated as L4, plays a critical role in sustaining oscillations by providing feedback to the circuit. The design's compactness is achieved through careful selection and arrangement of components, including a 220V ATX PC supply connector, which facilitates easy integration into the power supply system.

The system includes a dual-switch mechanism for filament voltage adjustment, allowing selection between nominal 12.6V and an under-nominal setting. This flexibility is vital for optimizing tube performance, as maintaining the correct filament voltage is crucial for the proper operation of the vacuum tube.

Experimentation with coil configurations was integral to the design process. By varying the number of turns and coil diameters, along with tuning the capacitors, the optimal conditions for spark generation and RF emissions were identified. This iterative process of testing and adjustment is essential in high-voltage applications where efficiency and performance are paramount.

The final coil design emerged as the most effective, demonstrating a balance between size and performance. The manual winding of the coil, while labor-intensive, allowed for precise control over its characteristics, ultimately leading to a successful implementation in the VTTC setup.

In the final assembly, the repositioning of electrolytic capacitors was necessary to accommodate the compact design, ensuring that all components fit harmoniously on the base. The use of additional wood to cover the capacitors not only enhances safety but also contributes to the aesthetic organization of the circuit. This careful consideration of layout and component placement is vital for achieving a reliable and efficient high-voltage circuit.A nice and compact setup, that works off-line, directly at 220V, with only a voltage doubler to get the plate voltage up to 560V DC. I don`t need to go into details explaining this circuit, it is a simple Armstrong oscillator, using the feedback coil L4.

Here is a great tutorial detailing all the basic knowledge and know-hows behind a VTTC. My goal was a compact design. I`ve used a 220V ATX PC Supply connector , a switch to power the tube, and another one to select the filament voltage (under-nominal and the nominal 12. 6V values). Careful, the voltage must be 12. 6V with the tube connected! I then tried various combination of secondaries and primaries coils, with variable number of turns or coil diameter, and adjusted the capacitors to get the best spark, RF emission, and power level.

This took some time, but it was an important step in the construction of this VTTC: It can be seen the last coil is a winner. Also it is more compact than the other 2, perfect for my setup. I had to wind it manually and this also took time, but at least I could use it successfully. For the final setup I had to move the electrolytic capacitors, and cover them with another piece of wood to make some space for the coil and oscillator and feedback caps, on the same base.

Got this nicely done: 🔗 External reference

This circuit design is based on a voltage doubler configuration that converts the standard 220V AC supply into a higher DC voltage suitable for the operation of a Vacuum Tube Tesla Coil (VTTC). The voltage doubler typically consists of two diodes and two capacitors arranged in a configuration that allows the peak voltage to be effectively doubled, thus achieving the necessary 560V DC for the plate voltage.

The Armstrong oscillator circuit is characterized by its simplicity and effectiveness in generating high-voltage oscillations. The feedback coil, designated as L4, plays a critical role in sustaining oscillations by providing feedback to the circuit. The design's compactness is achieved through careful selection and arrangement of components, including a 220V ATX PC supply connector, which facilitates easy integration into the power supply system.

The system includes a dual-switch mechanism for filament voltage adjustment, allowing selection between nominal 12.6V and an under-nominal setting. This flexibility is vital for optimizing tube performance, as maintaining the correct filament voltage is crucial for the proper operation of the vacuum tube.

Experimentation with coil configurations was integral to the design process. By varying the number of turns and coil diameters, along with tuning the capacitors, the optimal conditions for spark generation and RF emissions were identified. This iterative process of testing and adjustment is essential in high-voltage applications where efficiency and performance are paramount.

The final coil design emerged as the most effective, demonstrating a balance between size and performance. The manual winding of the coil, while labor-intensive, allowed for precise control over its characteristics, ultimately leading to a successful implementation in the VTTC setup.

In the final assembly, the repositioning of electrolytic capacitors was necessary to accommodate the compact design, ensuring that all components fit harmoniously on the base. The use of additional wood to cover the capacitors not only enhances safety but also contributes to the aesthetic organization of the circuit. This careful consideration of layout and component placement is vital for achieving a reliable and efficient high-voltage circuit.A nice and compact setup, that works off-line, directly at 220V, with only a voltage doubler to get the plate voltage up to 560V DC. I don`t need to go into details explaining this circuit, it is a simple Armstrong oscillator, using the feedback coil L4.

Here is a great tutorial detailing all the basic knowledge and know-hows behind a VTTC. My goal was a compact design. I`ve used a 220V ATX PC Supply connector , a switch to power the tube, and another one to select the filament voltage (under-nominal and the nominal 12. 6V values). Careful, the voltage must be 12. 6V with the tube connected! I then tried various combination of secondaries and primaries coils, with variable number of turns or coil diameter, and adjusted the capacitors to get the best spark, RF emission, and power level.

This took some time, but it was an important step in the construction of this VTTC: It can be seen the last coil is a winner. Also it is more compact than the other 2, perfect for my setup. I had to wind it manually and this also took time, but at least I could use it successfully. For the final setup I had to move the electrolytic capacitors, and cover them with another piece of wood to make some space for the coil and oscillator and feedback caps, on the same base.

Got this nicely done: 🔗 External reference