Voltage and Current Limited Audible Continuity Tester

This continuity tester circuit allows for the examination of PCB track failures without the need to visually inspect the routing of the tracks, which can often be frustrating.

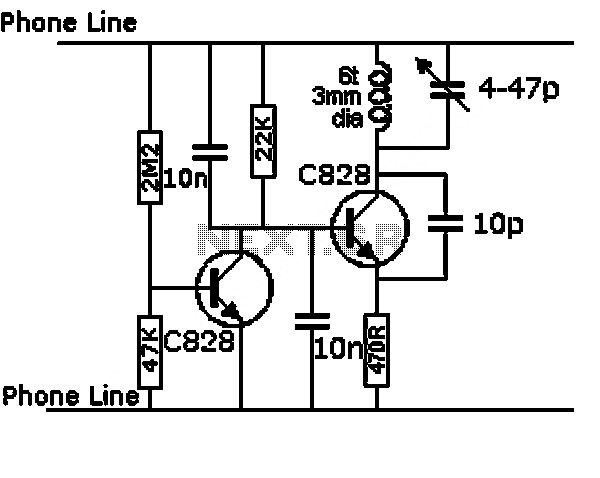

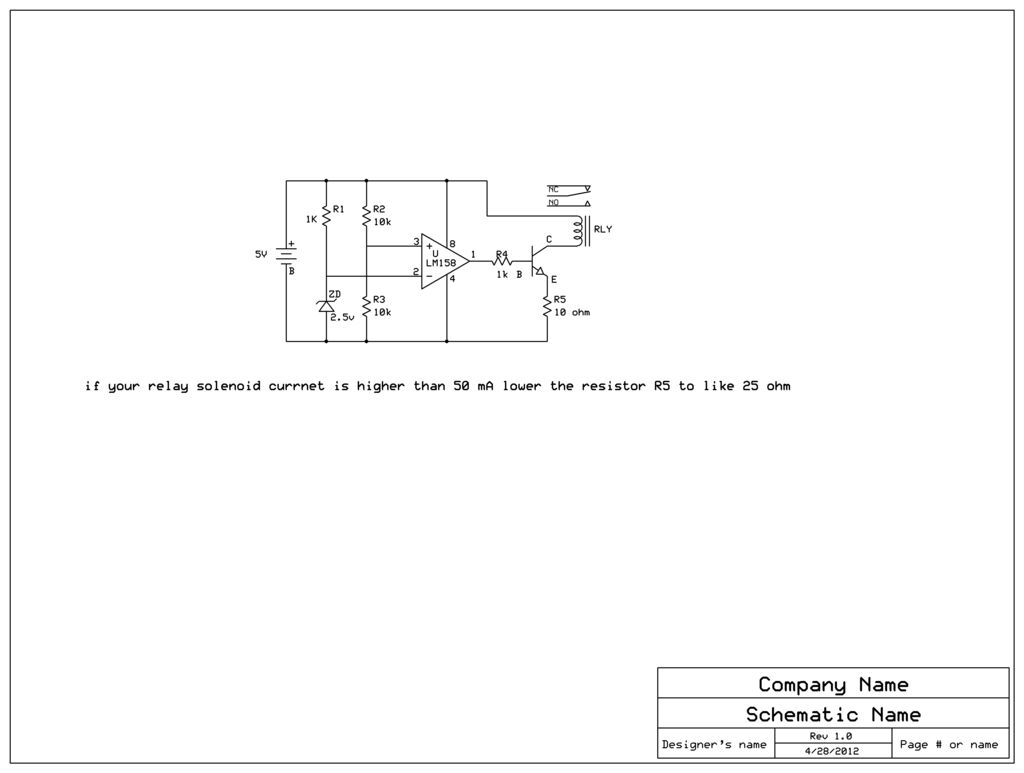

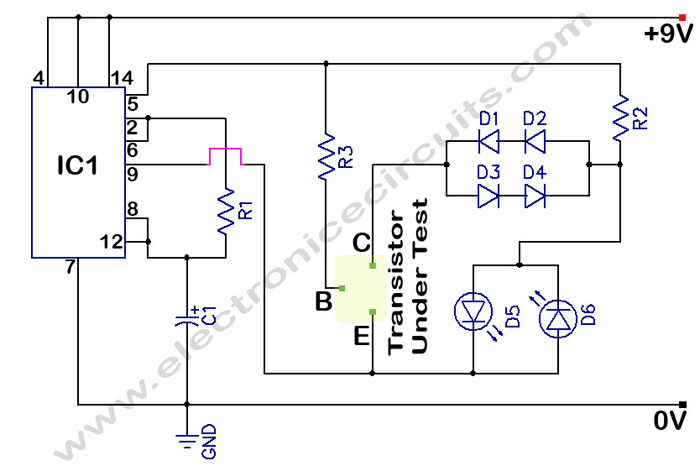

The continuity tester circuit is designed to facilitate the detection of faults in printed circuit board (PCB) tracks by providing a simple and effective means of testing connectivity. The circuit typically consists of a power source, a resistor, an LED indicator, and a testing probe.

When the circuit is powered, the LED indicator remains off, signifying that there is no continuity. When the testing probe contacts a point on the PCB track, the circuit path is completed if the track is intact. This completion allows current to flow through the resistor, illuminating the LED. The brightness of the LED can provide an indication of the quality of the connection; a dim light may suggest a weak connection, while a bright light indicates a strong, intact track.

The inclusion of a buzzer or audible indicator can enhance the functionality of the tester by providing an additional alert when continuity is detected. This feature is particularly useful in noisy environments where visual indicators may not be easily noticed.

The circuit can be powered by a standard battery, ensuring portability and ease of use in various settings. The design can be further refined by incorporating a microcontroller for advanced features such as automatic testing sequences, logging results, or integrating with a computer for data analysis.

Overall, the continuity tester circuit is an essential tool for electronics engineers and technicians, enabling efficient troubleshooting and maintenance of PCB assemblies without the need for direct visual inspection.Using this continuity tester circuit, a failure of? PCB tracks be examined without looking directly at the tracks routing, which is can be very frustrating 🔗 External reference

The continuity tester circuit is designed to facilitate the detection of faults in printed circuit board (PCB) tracks by providing a simple and effective means of testing connectivity. The circuit typically consists of a power source, a resistor, an LED indicator, and a testing probe.

When the circuit is powered, the LED indicator remains off, signifying that there is no continuity. When the testing probe contacts a point on the PCB track, the circuit path is completed if the track is intact. This completion allows current to flow through the resistor, illuminating the LED. The brightness of the LED can provide an indication of the quality of the connection; a dim light may suggest a weak connection, while a bright light indicates a strong, intact track.

The inclusion of a buzzer or audible indicator can enhance the functionality of the tester by providing an additional alert when continuity is detected. This feature is particularly useful in noisy environments where visual indicators may not be easily noticed.

The circuit can be powered by a standard battery, ensuring portability and ease of use in various settings. The design can be further refined by incorporating a microcontroller for advanced features such as automatic testing sequences, logging results, or integrating with a computer for data analysis.

Overall, the continuity tester circuit is an essential tool for electronics engineers and technicians, enabling efficient troubleshooting and maintenance of PCB assemblies without the need for direct visual inspection.Using this continuity tester circuit, a failure of? PCB tracks be examined without looking directly at the tracks routing, which is can be very frustrating 🔗 External reference