Water Level Sensor Circuit Using LM1830 Single Chip

This is a water sensor circuit design based on a Conductive Liquid Level Sensor. This single-chip circuit is compact and simple. It is an AC-excited fluid level sensor, which uses alternating current to provide biasing for the sensor probe, avoiding electrolysis of the probes. The AC excitation enhances the longevity of the sensing probe. This circuit can be utilized for a wide range of water or liquid level sensing and control applications, including radiators, beverage dispensers, washing machines, water softeners, irrigation systems, reservoirs, boilers, aquariums, and sump pumps. Many types of fluids are electrically conductive and can be detected using this liquid level sensor circuit, such as city water, groundwater, seawater, chopper sulfate solution, weak acids, weak bases, household ammonia, water and glycol mixtures, wet soil, coffee, and fruit juices. It is important to note that most fuels do not conduct electricity, allowing this circuit to function as a fuel level sensor/detector. According to the datasheet, this water level sensor circuit chip operates best at a supply voltage of 10-24 volts, with an absolute maximum voltage supply of 28 volts; however, it is advisable to avoid operating at this extreme to prevent damage to the chip. In the first circuit, a basic low-level warning application uses an LED to indicate when the water level falls below the sensor. The filter pin (9) is not connected, resulting in the LED blinking at a sound frequency, which is acceptable since the human eye can perceive such high-speed blinking. Without a filter capacitor at pin 9, the output generates a square wave signal, allowing for easy substitution of the LED with a loudspeaker to provide an audio indication in the second circuit. For TTL or CMOS levels, a filtering capacitor should be connected to pin 9, and an open collector output can be used to drive a pull-up resistor connected to a desired voltage supply. For water level control or any conductive liquid level control, a relay can be employed to activate a motor or valve to manage the level. The third circuit illustrates this application, with the relay serving as a liquid/water level switch. An optional resistor in the third circuit is available to protect against high voltage transients common in automotive environments, though it can be omitted if such conditions are not present.

The water sensor circuit operates effectively by utilizing a conductive liquid level sensor, which is designed to detect various conductive liquids through its AC excitation mechanism. The alternating current not only ensures accurate detection but also extends the life of the sensor probes by minimizing electrolysis, a common issue with DC-operated sensors. The circuit can be implemented in multiple applications due to its versatility in detecting different conductive fluids, making it suitable for both household and industrial uses.

The basic circuit configuration includes a power supply unit, typically ranging from 10 to 24 volts, which provides the necessary voltage to the sensor chip. The output can be configured to drive different types of indicators, such as LEDs for visual alerts or speakers for audio notifications, depending on the application requirements. The use of a relay in the control circuit allows for the integration of larger loads, such as pumps or valves, which can be activated or deactivated based on the liquid level detected by the sensor.

In addition to the primary functions of sensing and indicating liquid levels, the circuit can be enhanced with additional components such as filtering capacitors to improve signal stability and reduce noise, ensuring reliable operation in various environments. The optional resistor for transient protection is particularly important in automotive applications, where voltage spikes can occur. Overall, this water sensor circuit design provides a robust solution for liquid level detection and control across diverse applications, combining simplicity with effective functionality.This is a water sensor circuit design using based on a Conductive Liquid Level Sensor, this single chip circuit is very compact and simple. This circuit is an ac excited fluid level sensor, which uses alternating current to provide biasing for the sensor probe to avoid electrolysis of the probes.

This ac excitation makes the sensing probe has long er lifetime. This circuit can be useful for wide range of water or liquid level sensing and control such as radiators, beverage dispensers, washing machines, water softeners, irrigation, reservoirs, boilers, aquarium, or sump pumps Many type of fluids are electrically conductive and can be detected using this liquid level sensor circuit: city water/ground water, sea water, chopper sulfate solution, weak acid, weak base, household ammonia, water and glycol mixture, wet soil, coffee, or fruit juices. Remember that most of fuel doesn`t conduct electricity, so this circuit can be employed as fuel level sensor/detector.

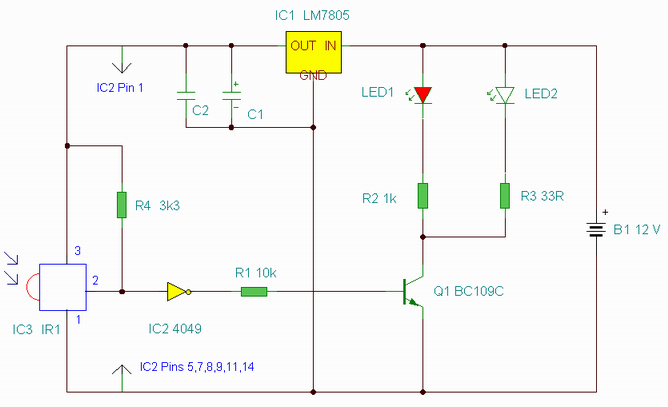

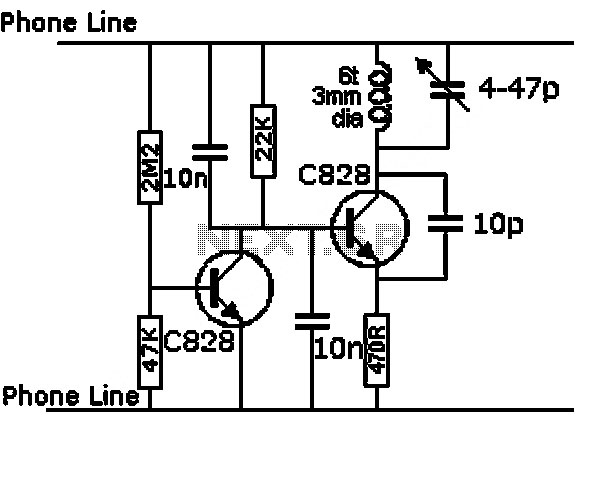

This is the figure of the circuit. If we look at its data sheet, this water level sensor circuit chip is best at 10-24 volt supply voltage. The absolute maximum voltage supply for this liquid level sensor chip is 28V, but remembers to always try to avoid this extreme condition to prevent damaging the chip.

In the first circuit, a basic low level warning application uses a LED to indicate the water level falls below the sensor. You can see the filter pin (9) is not connected, this means that the LED is actually blinking at sound frequency, but it`s fine since our eye response is slow enough to notice such high speed blinking.

Since without filter capacitor at pin 9 the output give a square wave signal, you can easily replace the led with loud speaker as shown in the second circuit to give audio indication. If you need a TTL or CMOS level then you should use a filtering capacitor connected to pin 9 and use the open collector output to drive a pull up resistor connected to a voltage supply at desired voltage level.

For water level control, or any conductive liquid level control, you can use a relay to activate a motor or valve to control the level. The third circuit show this kind of application, and the relay can be seen as liquid/water level switch.

The optional resistor seen in the third circuit is an option for high voltage transient that often occurs in automotive environment, and you can omit it if there is no such possibility. [Circuit`s schematic diagram source: National Semiconductor Application Notes] 🔗 External reference

The water sensor circuit operates effectively by utilizing a conductive liquid level sensor, which is designed to detect various conductive liquids through its AC excitation mechanism. The alternating current not only ensures accurate detection but also extends the life of the sensor probes by minimizing electrolysis, a common issue with DC-operated sensors. The circuit can be implemented in multiple applications due to its versatility in detecting different conductive fluids, making it suitable for both household and industrial uses.

The basic circuit configuration includes a power supply unit, typically ranging from 10 to 24 volts, which provides the necessary voltage to the sensor chip. The output can be configured to drive different types of indicators, such as LEDs for visual alerts or speakers for audio notifications, depending on the application requirements. The use of a relay in the control circuit allows for the integration of larger loads, such as pumps or valves, which can be activated or deactivated based on the liquid level detected by the sensor.

In addition to the primary functions of sensing and indicating liquid levels, the circuit can be enhanced with additional components such as filtering capacitors to improve signal stability and reduce noise, ensuring reliable operation in various environments. The optional resistor for transient protection is particularly important in automotive applications, where voltage spikes can occur. Overall, this water sensor circuit design provides a robust solution for liquid level detection and control across diverse applications, combining simplicity with effective functionality.This is a water sensor circuit design using based on a Conductive Liquid Level Sensor, this single chip circuit is very compact and simple. This circuit is an ac excited fluid level sensor, which uses alternating current to provide biasing for the sensor probe to avoid electrolysis of the probes.

This ac excitation makes the sensing probe has long er lifetime. This circuit can be useful for wide range of water or liquid level sensing and control such as radiators, beverage dispensers, washing machines, water softeners, irrigation, reservoirs, boilers, aquarium, or sump pumps Many type of fluids are electrically conductive and can be detected using this liquid level sensor circuit: city water/ground water, sea water, chopper sulfate solution, weak acid, weak base, household ammonia, water and glycol mixture, wet soil, coffee, or fruit juices. Remember that most of fuel doesn`t conduct electricity, so this circuit can be employed as fuel level sensor/detector.

This is the figure of the circuit. If we look at its data sheet, this water level sensor circuit chip is best at 10-24 volt supply voltage. The absolute maximum voltage supply for this liquid level sensor chip is 28V, but remembers to always try to avoid this extreme condition to prevent damaging the chip.

In the first circuit, a basic low level warning application uses a LED to indicate the water level falls below the sensor. You can see the filter pin (9) is not connected, this means that the LED is actually blinking at sound frequency, but it`s fine since our eye response is slow enough to notice such high speed blinking.

Since without filter capacitor at pin 9 the output give a square wave signal, you can easily replace the led with loud speaker as shown in the second circuit to give audio indication. If you need a TTL or CMOS level then you should use a filtering capacitor connected to pin 9 and use the open collector output to drive a pull up resistor connected to a voltage supply at desired voltage level.

For water level control, or any conductive liquid level control, you can use a relay to activate a motor or valve to control the level. The third circuit show this kind of application, and the relay can be seen as liquid/water level switch.

The optional resistor seen in the third circuit is an option for high voltage transient that often occurs in automotive environment, and you can omit it if there is no such possibility. [Circuit`s schematic diagram source: National Semiconductor Application Notes] 🔗 External reference