Wearable hypoxia monitoring circuit design

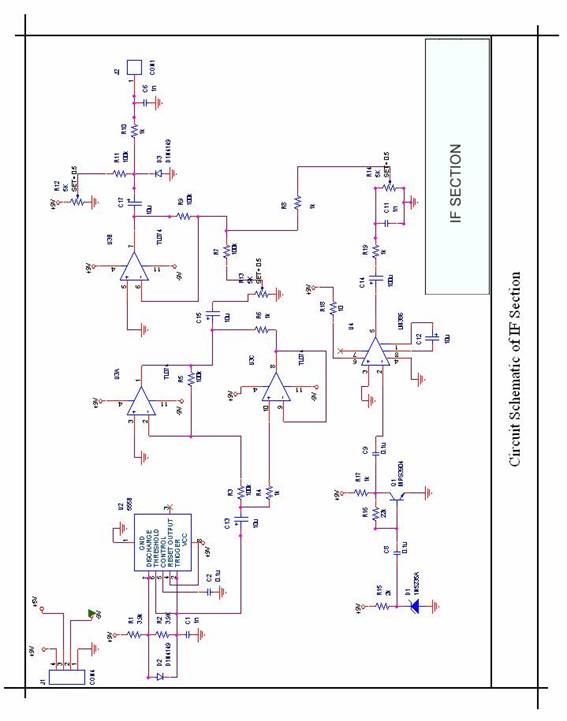

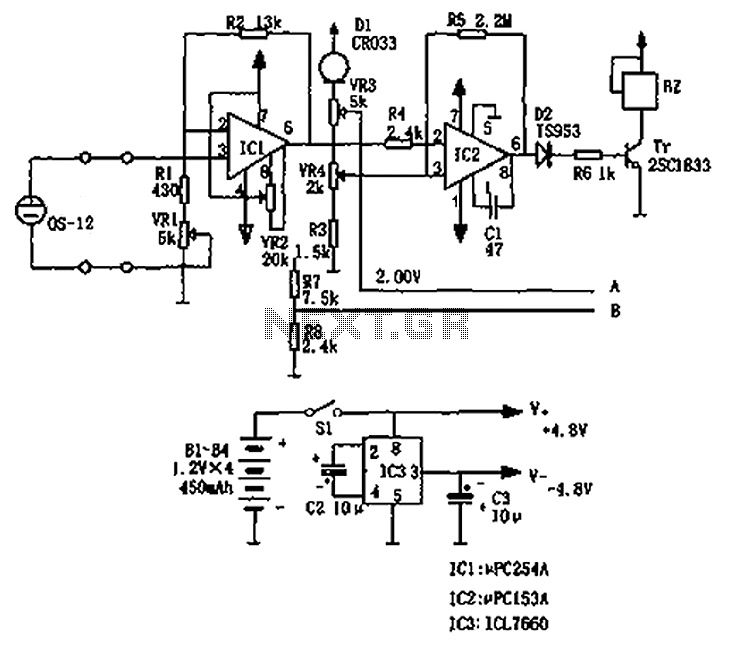

The circuit principle involves an oxygen sensor circuit utilizing the OS-12, a DC amplifier IC1, an A/D converter IC4, a liquid crystal display F2100-34PI, a voltage comparator IC2, and a positive and negative power converter IC, among other components. The OS-12 functions as a galvanic cell type oxygen sensor, capable of detecting oxygen levels in the air, providing an output signal of approximately 50mV. This output has a linear response over a range of 0 to 100% oxygen concentration, allowing for precise measurement through the A/D converter. IC1 serves as a DC amplifier that can amplify the sensor’s output signal by up to 8 times. The amplified signal is processed by IC4 (ICL7107 type), which performs A/D conversion and directly drives the liquid crystal display, showcasing the digital representation of oxygen concentration. The ICL7107 is a 3.5-digit A/D converter that, when used with an LED display, reduces current consumption to about 1mA. A constant current diode D1 is used to provide the reference voltage for the A/D converter. CR033 utilizes a FET device with a constant current characteristic, maintaining a current of 330 µA with a temperature coefficient close to zero. The voltage comparator IC2 utilizes the reference voltage from D1 to monitor oxygen concentrations, triggering an alarm for levels at or below 18%. IC3 is responsible for converting the positive supply to a negative supply with low leakage current. The circuit is powered by 4 NiCd batteries, providing 450mA and enabling continuous operation for approximately 100 hours. This circuit is designed to monitor oxygen concentration in environments such as underground tunnels and caves, helping to prevent hypoxia-related accidents.

The oxygen sensor circuit is a sophisticated assembly designed for accurate monitoring of oxygen levels in various environments. The OS-12 sensor operates through a galvanic cell mechanism, generating a small voltage output that corresponds to the concentration of oxygen present in the air. This output is critical for safety applications, particularly in confined spaces where oxygen depletion can pose serious hazards.

The DC amplifier IC1 amplifies the low-level signal from the OS-12 sensor, enhancing the signal to a more manageable level for further processing. The amplification factor of up to 8 times ensures that even minimal changes in oxygen concentration can be detected and displayed accurately.

Following amplification, the signal is fed into the A/D converter IC4, specifically the ICL7107, which is adept at converting the analog signal into a digital format. The ICL7107 is known for its efficiency, particularly in low-power applications, making it suitable for battery-operated devices. The conversion process results in a digital output that is directly displayed on the F2100-34PI liquid crystal display, providing real-time feedback on oxygen levels.

The inclusion of a constant current diode D1 stabilizes the reference voltage for the A/D converter, ensuring consistent performance across varying conditions. CR033, with its FET characteristics, maintains a stable current output, which is crucial for maintaining accuracy in readings, especially in fluctuating temperature environments.

The voltage comparator IC2 plays a vital role in safety monitoring by detecting when oxygen levels drop below 18%. This threshold is critical for triggering alarms and alerts, thereby enhancing workplace safety in potentially hazardous environments.

The power supply design, featuring a negative and positive converter IC, ensures that the circuit operates efficiently with minimal leakage current. The choice of NiCd batteries provides a reliable power source, with a capacity that allows for prolonged usage without the need for frequent replacements, making the circuit practical for field applications.

Overall, this oxygen sensor circuit is a well-engineered solution for monitoring air quality in environments where oxygen levels can be dangerously low, effectively contributing to safety measures in various industrial and occupational settings. Circuit principle : the oxygen sensor circuit by the OS-12, DC amplifier IC1, A/D converter IC4, a liquid crystal display F2100-34PI, the voltage comparator IC2, the positive a nd negative power converter IC. And other components. OS-12 for the galvanic cell type oxygen sensor to detect oxygen in the air may be the output signal of about 50mV, and its linear output from 0 to 100% oxygen concentration range, its output - input A/D converter It can be very accurately with a digital display of the oxygen concentration. IC1 is a DC amplifier, the output signal of the sensor can be expanded up to 8 times. The amplified signal is IC4 (ICL7107 type) after A/D conversion directly driving the liquid crystal display, digital display of oxygen concentration.

ICL7107 is 3.5 chip A/D converter, and the LED display when used in combination, the current consumption can be reduced to about 1mA. It is a constant current diode D1 to A/D-converter reference voltage. CR033 is the use of a constant current characteristic of the FET device, when providing a current 330 A, the temperature coefficient close to zero.

Voltage comparator IC2 D1 obtained from the reference voltage, for detecting oxygen concentration of 18% or less, the oxygen concentration is low alarm. IC3 is from the positive supply to the negative supply converter itself low leakage current. Power 4 450mA of NiCd batteries can be used continuously l00h. The circuit can monitor the concentration of oxygen at the bottom of underground tunnels and caves and other workplace to prevent hypoxia accidents.

The oxygen sensor circuit is a sophisticated assembly designed for accurate monitoring of oxygen levels in various environments. The OS-12 sensor operates through a galvanic cell mechanism, generating a small voltage output that corresponds to the concentration of oxygen present in the air. This output is critical for safety applications, particularly in confined spaces where oxygen depletion can pose serious hazards.

The DC amplifier IC1 amplifies the low-level signal from the OS-12 sensor, enhancing the signal to a more manageable level for further processing. The amplification factor of up to 8 times ensures that even minimal changes in oxygen concentration can be detected and displayed accurately.

Following amplification, the signal is fed into the A/D converter IC4, specifically the ICL7107, which is adept at converting the analog signal into a digital format. The ICL7107 is known for its efficiency, particularly in low-power applications, making it suitable for battery-operated devices. The conversion process results in a digital output that is directly displayed on the F2100-34PI liquid crystal display, providing real-time feedback on oxygen levels.

The inclusion of a constant current diode D1 stabilizes the reference voltage for the A/D converter, ensuring consistent performance across varying conditions. CR033, with its FET characteristics, maintains a stable current output, which is crucial for maintaining accuracy in readings, especially in fluctuating temperature environments.

The voltage comparator IC2 plays a vital role in safety monitoring by detecting when oxygen levels drop below 18%. This threshold is critical for triggering alarms and alerts, thereby enhancing workplace safety in potentially hazardous environments.

The power supply design, featuring a negative and positive converter IC, ensures that the circuit operates efficiently with minimal leakage current. The choice of NiCd batteries provides a reliable power source, with a capacity that allows for prolonged usage without the need for frequent replacements, making the circuit practical for field applications.

Overall, this oxygen sensor circuit is a well-engineered solution for monitoring air quality in environments where oxygen levels can be dangerously low, effectively contributing to safety measures in various industrial and occupational settings. Circuit principle : the oxygen sensor circuit by the OS-12, DC amplifier IC1, A/D converter IC4, a liquid crystal display F2100-34PI, the voltage comparator IC2, the positive a nd negative power converter IC. And other components. OS-12 for the galvanic cell type oxygen sensor to detect oxygen in the air may be the output signal of about 50mV, and its linear output from 0 to 100% oxygen concentration range, its output - input A/D converter It can be very accurately with a digital display of the oxygen concentration. IC1 is a DC amplifier, the output signal of the sensor can be expanded up to 8 times. The amplified signal is IC4 (ICL7107 type) after A/D conversion directly driving the liquid crystal display, digital display of oxygen concentration.

ICL7107 is 3.5 chip A/D converter, and the LED display when used in combination, the current consumption can be reduced to about 1mA. It is a constant current diode D1 to A/D-converter reference voltage. CR033 is the use of a constant current characteristic of the FET device, when providing a current 330 A, the temperature coefficient close to zero.

Voltage comparator IC2 D1 obtained from the reference voltage, for detecting oxygen concentration of 18% or less, the oxygen concentration is low alarm. IC3 is from the positive supply to the negative supply converter itself low leakage current. Power 4 450mA of NiCd batteries can be used continuously l00h. The circuit can monitor the concentration of oxygen at the bottom of underground tunnels and caves and other workplace to prevent hypoxia accidents.