Wiring A Motor Control Electrical

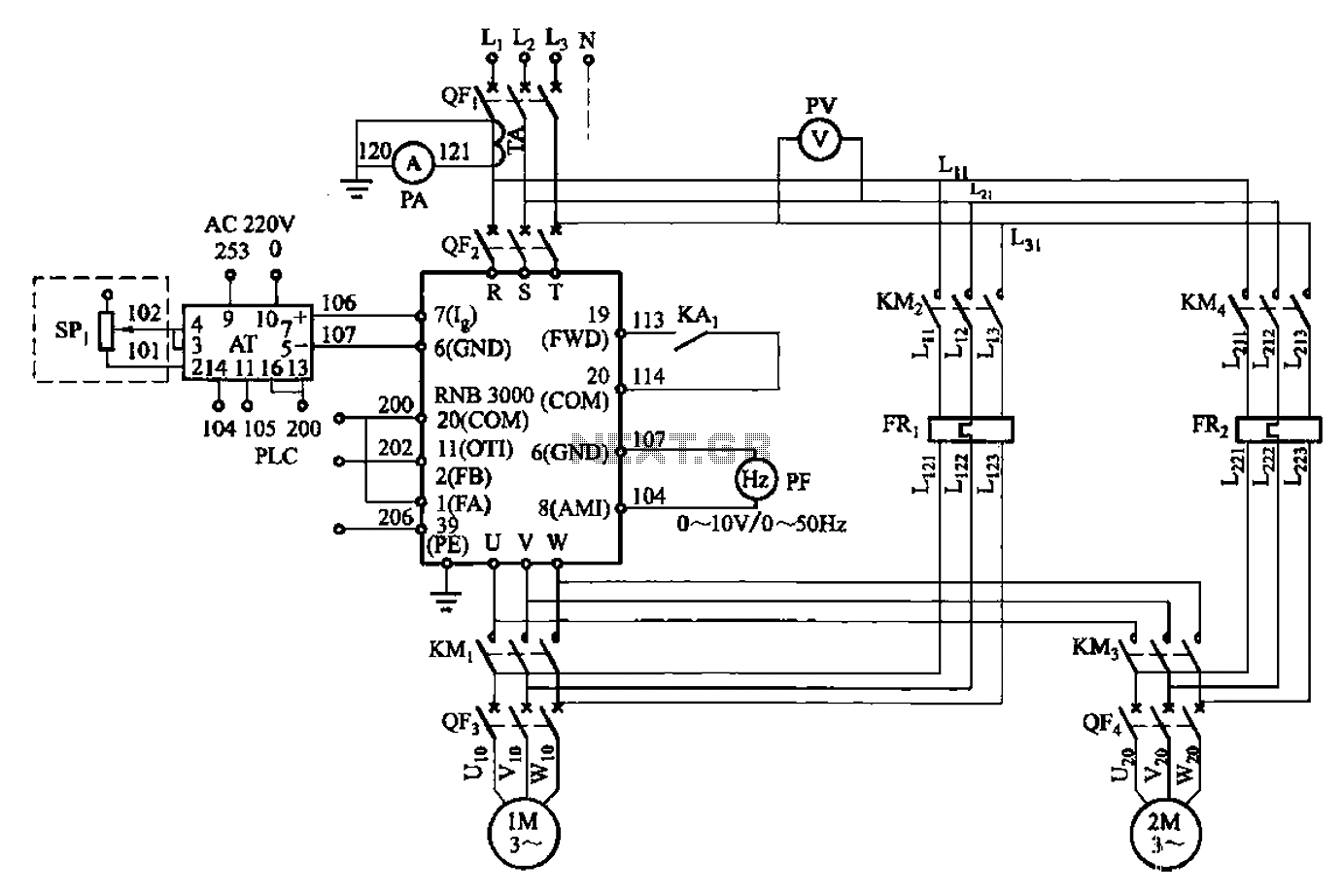

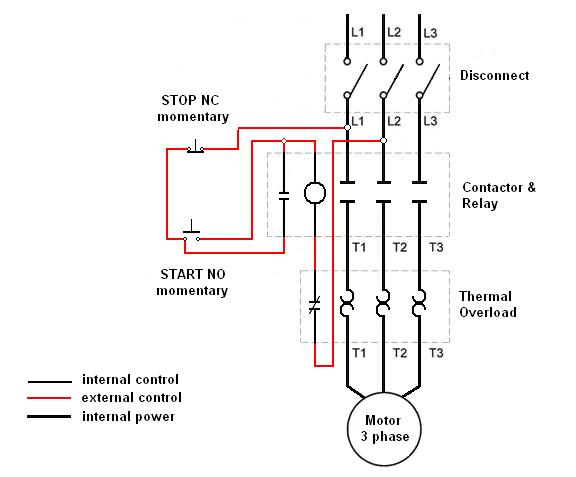

Wiring a three-phase motor through a two-pole vacuum switch involves two lines passing through the switch while one line remains continuously energized to the motor. Is this configuration correct, or does it present a safety concern?

When wiring a three-phase motor using a two-pole vacuum switch, it is essential to ensure that the configuration adheres to safety standards and operational efficiency. A three-phase motor typically requires three separate phases (L1, L2, L3) for proper operation. In this scenario, the use of a two-pole switch means that only two of the three phases are being switched on and off, while one phase remains continuously connected to the motor.

This setup can lead to several potential issues. Firstly, if one phase is always hot, the motor may experience an imbalance in the phase supply, which can lead to overheating, increased wear, and reduced efficiency. Additionally, operating a three-phase motor with only two phases can cause it to run in an unbalanced condition, risking damage to the motor windings.

From a safety perspective, having one line always hot while the others are switched off can pose risks during maintenance or troubleshooting, as there is a potential for accidental contact with live components. It is advisable to utilize a three-pole switch designed for three-phase applications, which ensures that all phases can be disconnected simultaneously, enhancing both safety and functionality.

In summary, for optimal performance and safety, it is recommended to re-evaluate the current wiring configuration and consider implementing a three-pole switch that allows for complete disconnection of all phases, thereby ensuring that the motor operates under balanced conditions and reducing the risk of electrical hazards.I am wiring a three phase motor through a two pole vacuum switch. two lines go through the switch but one line is always hot to the motor. is this proper or is this a safety issue?.. 🔗 External reference

When wiring a three-phase motor using a two-pole vacuum switch, it is essential to ensure that the configuration adheres to safety standards and operational efficiency. A three-phase motor typically requires three separate phases (L1, L2, L3) for proper operation. In this scenario, the use of a two-pole switch means that only two of the three phases are being switched on and off, while one phase remains continuously connected to the motor.

This setup can lead to several potential issues. Firstly, if one phase is always hot, the motor may experience an imbalance in the phase supply, which can lead to overheating, increased wear, and reduced efficiency. Additionally, operating a three-phase motor with only two phases can cause it to run in an unbalanced condition, risking damage to the motor windings.

From a safety perspective, having one line always hot while the others are switched off can pose risks during maintenance or troubleshooting, as there is a potential for accidental contact with live components. It is advisable to utilize a three-pole switch designed for three-phase applications, which ensures that all phases can be disconnected simultaneously, enhancing both safety and functionality.

In summary, for optimal performance and safety, it is recommended to re-evaluate the current wiring configuration and consider implementing a three-pole switch that allows for complete disconnection of all phases, thereby ensuring that the motor operates under balanced conditions and reducing the risk of electrical hazards.I am wiring a three phase motor through a two pole vacuum switch. two lines go through the switch but one line is always hot to the motor. is this proper or is this a safety issue?.. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713