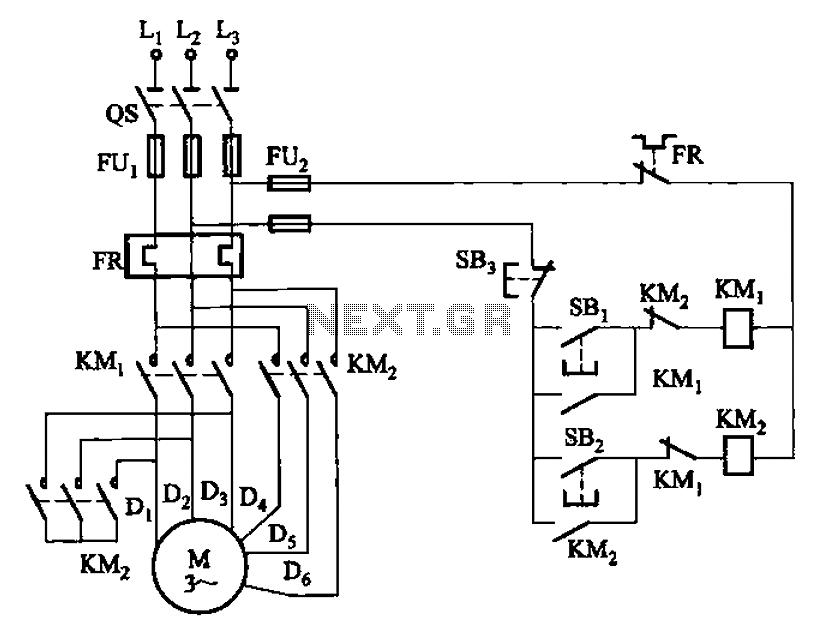

2Y- connection two-speed motor contactor control circuit 2

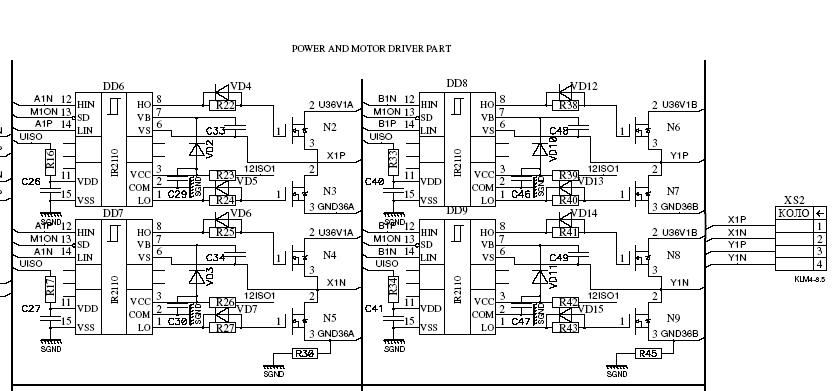

The circuit illustrated in Figure 3-97 features two contacts and is designed specifically for a 2kW dual-speed motor. In this configuration, SB1 is utilized for low-speed operation, while SB2 serves as the high-speed run button.

The circuit operates by allowing the user to select between two distinct speed settings for the motor, enabling efficient performance based on the application's requirements. The low-speed setting, activated by the SB1 button, is typically used for tasks that require more torque and less speed, making it suitable for applications such as starting heavy loads or operating machinery that benefits from controlled acceleration. Conversely, the high-speed setting, engaged through the SB2 button, facilitates faster operation, ideal for tasks that require quick movement or reduced processing time.

The two contacts in the circuit serve as switches that control the flow of current to the motor, effectively changing its operational speed. The design ensures that only one speed can be active at a time, preventing potential damage to the motor or the circuit itself. This is often achieved through a simple relay or contactor mechanism that engages the appropriate speed setting based on the button pressed.

In summary, the circuit in Figure 3-97 represents a straightforward yet effective solution for controlling a dual-speed motor, optimizing its performance for varying operational demands. The clear distinction between low and high-speed operation, facilitated by the respective buttons, enhances usability and operational flexibility. Circuit shown in Figure 3-97. The circuit only two contacts, the circuit is simple, but only applies to the following 2kW dual speed motor. Figure, SBi is running at low speed button, SBz high-speed run button.

The circuit operates by allowing the user to select between two distinct speed settings for the motor, enabling efficient performance based on the application's requirements. The low-speed setting, activated by the SB1 button, is typically used for tasks that require more torque and less speed, making it suitable for applications such as starting heavy loads or operating machinery that benefits from controlled acceleration. Conversely, the high-speed setting, engaged through the SB2 button, facilitates faster operation, ideal for tasks that require quick movement or reduced processing time.

The two contacts in the circuit serve as switches that control the flow of current to the motor, effectively changing its operational speed. The design ensures that only one speed can be active at a time, preventing potential damage to the motor or the circuit itself. This is often achieved through a simple relay or contactor mechanism that engages the appropriate speed setting based on the button pressed.

In summary, the circuit in Figure 3-97 represents a straightforward yet effective solution for controlling a dual-speed motor, optimizing its performance for varying operational demands. The clear distinction between low and high-speed operation, facilitated by the respective buttons, enhances usability and operational flexibility. Circuit shown in Figure 3-97. The circuit only two contacts, the circuit is simple, but only applies to the following 2kW dual speed motor. Figure, SBi is running at low speed button, SBz high-speed run button.