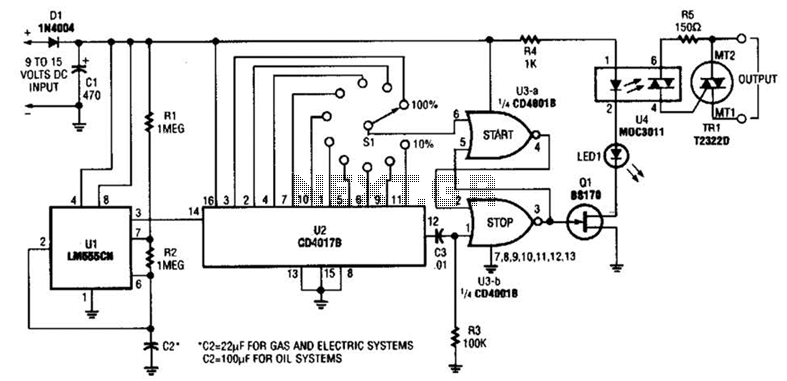

Furnace Fuel Miser Circuit

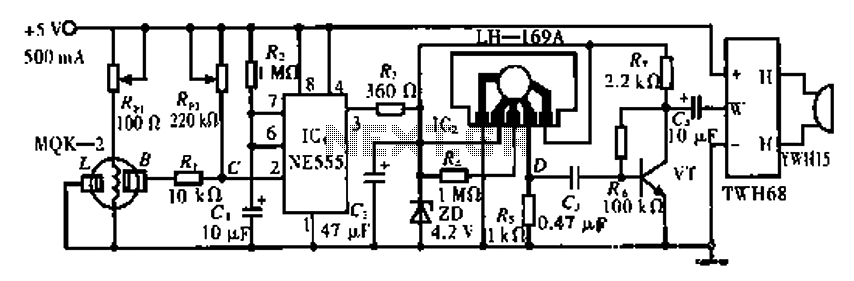

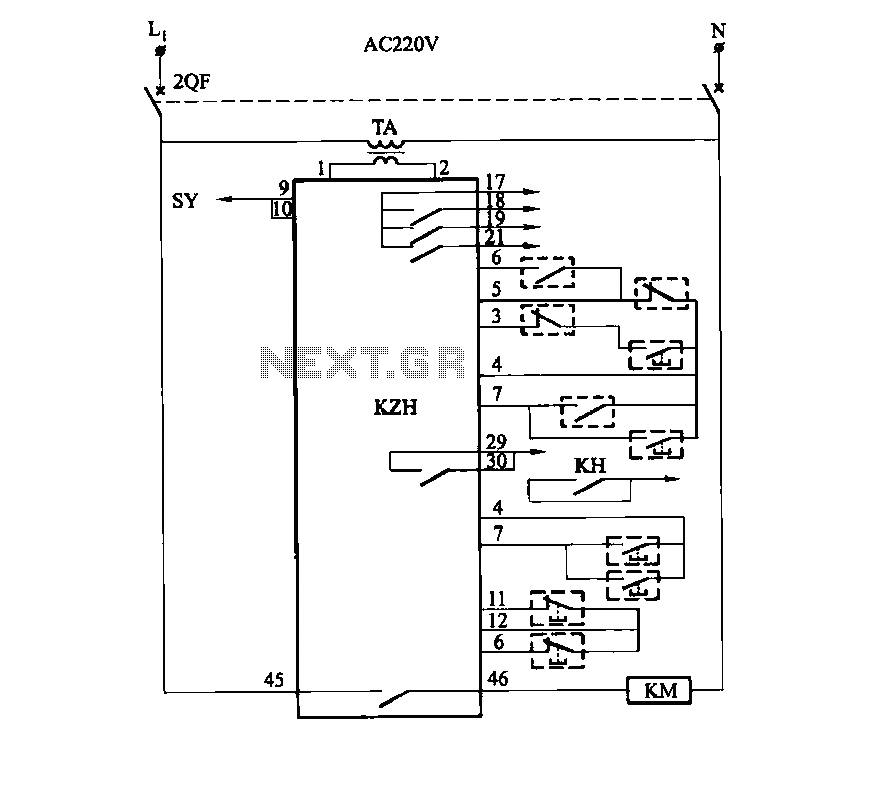

A timer (LM555CN) and decode counter are utilized to generate duty cycles ranging from 10% to 100% for controlling the operational time of a heating system. V2 operates as a decode counter that can be adjusted for duty cycles between 10% and 100%. V3A, in conjunction with another component, forms a latch that drives Al, LED1, and V4. The triac (TRI) functions as an AC switch in series with the thermostat that regulates the heating system. Electric heating systems that do not include a low-current thermostat, as seen in previous installations, require a heavy-duty thermostat that directly supplies current to the heating element. For these systems, it is essential to install a heavy-duty relay (K1 in this example) to manage the high current flowing to the heating element. Additionally, certain oil-fired systems utilize three-wire thermostats to control the burner motor and ignition system by activating a relay, which is a standard configuration for these systems.

The schematic design incorporates an LM555 timer configured in astable mode to generate a pulse-width modulation (PWM) signal that adjusts the duty cycle. This PWM signal is then fed into a decode counter (V2), which can be programmed to output specific duty cycles, allowing precise control over the heating duration. The output from V2 is linked to a latch circuit formed by V3A and another component, which ensures that the control signals for the heating system components, including Al and LED1, are stable and reliable.

The triac (TRI) is employed as a switching device to control the AC supply to the heating system. When the triac is triggered, it allows current to flow through the heating element, effectively controlling the heating process. The integration of a heavy-duty relay (K1) is crucial for systems that require higher current handling, ensuring that the relay can manage the load without failure.

In scenarios where oil-fired heating systems are used, the schematic accounts for the inclusion of a three-wire thermostat. This thermostat is responsible for managing the burner motor and ignition system, activating a relay to facilitate operation. This relay acts as a safety and control mechanism, ensuring that the heating system operates efficiently and safely.

Overall, the described circuit effectively combines timing, control, and high-current switching elements to create a robust heating control system. The design ensures flexibility in duty cycle adjustments while maintaining safety and reliability in operation. A timer (LM555CN) and decode counter is used to generate duty cycles from 10% to 100% to control the time a heating system can operate. V2 is a decode counter that can be switched from 10% to 100% duty cycle. V3A and form a latch that drive Al, LED1, and V4. The triac TRI is used as an ac switch, in series with the thermostat that controls the heating system.

Electric-heating systems thai do nut contain a low-current thermostat (as in the previous installation), use a heavy-duty thermostat that directly feeds current to the heating element.For such systems, it will be necessary to install a heavy-duty relay (Kl in this example) to control the heavy heating-element current. Some oil-fired systems use three-wire thermostats to control the operation of the burner motor and ignition system by activating a relay. This is a typical installation for such systems.

The schematic design incorporates an LM555 timer configured in astable mode to generate a pulse-width modulation (PWM) signal that adjusts the duty cycle. This PWM signal is then fed into a decode counter (V2), which can be programmed to output specific duty cycles, allowing precise control over the heating duration. The output from V2 is linked to a latch circuit formed by V3A and another component, which ensures that the control signals for the heating system components, including Al and LED1, are stable and reliable.

The triac (TRI) is employed as a switching device to control the AC supply to the heating system. When the triac is triggered, it allows current to flow through the heating element, effectively controlling the heating process. The integration of a heavy-duty relay (K1) is crucial for systems that require higher current handling, ensuring that the relay can manage the load without failure.

In scenarios where oil-fired heating systems are used, the schematic accounts for the inclusion of a three-wire thermostat. This thermostat is responsible for managing the burner motor and ignition system, activating a relay to facilitate operation. This relay acts as a safety and control mechanism, ensuring that the heating system operates efficiently and safely.

Overall, the described circuit effectively combines timing, control, and high-current switching elements to create a robust heating control system. The design ensures flexibility in duty cycle adjustments while maintaining safety and reliability in operation. A timer (LM555CN) and decode counter is used to generate duty cycles from 10% to 100% to control the time a heating system can operate. V2 is a decode counter that can be switched from 10% to 100% duty cycle. V3A and form a latch that drive Al, LED1, and V4. The triac TRI is used as an ac switch, in series with the thermostat that controls the heating system.

Electric-heating systems thai do nut contain a low-current thermostat (as in the previous installation), use a heavy-duty thermostat that directly feeds current to the heating element.For such systems, it will be necessary to install a heavy-duty relay (Kl in this example) to control the heavy heating-element current. Some oil-fired systems use three-wire thermostats to control the operation of the burner motor and ignition system by activating a relay. This is a typical installation for such systems.