3 phase ac motor speed control circuit

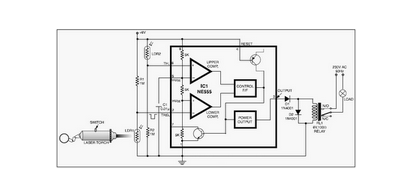

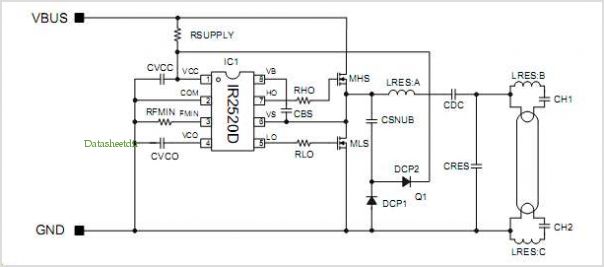

Controlling the speed of a three-phase AC motor is achieved by regulating the frequency of the power supply, as the motor operates in synchronization with the line frequency. A three-phase AC motor speed controller functions as a three-phase sine wave power inverter with variable frequency. This inverter circuit is complex; however, an integrated circuit chip is available for this application. In the final motor driver circuit, component values are specified only for the OB2 channel, with the others being similar. This three-phase AC motor controller employs optical isolation, necessitating careful design of the layout to ensure a clear separation between low and high voltage networks, thereby minimizing the risk of hazardous electrical shock.

The three-phase AC motor speed controller is implemented through a sine wave inverter, which converts the DC supply voltage into a three-phase AC output with adjustable frequency. The core of the circuit typically includes a microcontroller or a digital signal processor (DSP) that generates the required PWM (Pulse Width Modulation) signals to control the switching devices, such as MOSFETs or IGBTs, in the inverter stage. These devices are arranged in a three-phase bridge configuration to produce the necessary output waveforms.

The integrated circuit chip designed for this purpose simplifies the control of the inverter, allowing for precise frequency adjustments that directly influence motor speed. The PWM technique modulates the duty cycle of the output signals, effectively controlling the voltage applied to the motor. This modulation results in a variable frequency output, which is essential for speed control.

Optical isolation is implemented using opto-isolators to protect the low voltage control circuit from the high voltage power circuit. This is critical for ensuring operator safety and protecting sensitive components from voltage spikes or transients. The layout of the circuit must be meticulously designed, ensuring that high and low voltage traces are adequately separated to prevent interference and reduce the risk of electrical shock.

In the final design, careful consideration of component ratings, thermal management, and filtering techniques is necessary to enhance the reliability and efficiency of the motor controller. The selection of appropriate capacitors, inductors, and heat sinks will play a significant role in the overall performance and longevity of the device. Furthermore, implementing feedback mechanisms, such as current sensing and speed feedback loops, can improve the control accuracy and responsiveness of the motor speed controller.Controlling the speed of three phase ac motor is done by controlling the frequency of the power line supply, since the motor is synchronized with the line frequency. Three phase ac motor speed controller is actually nothing more than three phase sine wave power inverter with variable frequency.

The three phase power inverter is a complex circuit, but fortunately there is an integrated circuit chip for this purpose. This is the figure of the circuit; For the final motor driver circuit, you can see the component values are shown only for OB2 channel, but the others are similar. This 3 phase ac motor controller use optical isolation, so you must be careful in designing the layout, to make a clear separation between low and high voltage network.

This separation is useful for minimizing the risk of hazardouz electrical shock. 🔗 External reference

The three-phase AC motor speed controller is implemented through a sine wave inverter, which converts the DC supply voltage into a three-phase AC output with adjustable frequency. The core of the circuit typically includes a microcontroller or a digital signal processor (DSP) that generates the required PWM (Pulse Width Modulation) signals to control the switching devices, such as MOSFETs or IGBTs, in the inverter stage. These devices are arranged in a three-phase bridge configuration to produce the necessary output waveforms.

The integrated circuit chip designed for this purpose simplifies the control of the inverter, allowing for precise frequency adjustments that directly influence motor speed. The PWM technique modulates the duty cycle of the output signals, effectively controlling the voltage applied to the motor. This modulation results in a variable frequency output, which is essential for speed control.

Optical isolation is implemented using opto-isolators to protect the low voltage control circuit from the high voltage power circuit. This is critical for ensuring operator safety and protecting sensitive components from voltage spikes or transients. The layout of the circuit must be meticulously designed, ensuring that high and low voltage traces are adequately separated to prevent interference and reduce the risk of electrical shock.

In the final design, careful consideration of component ratings, thermal management, and filtering techniques is necessary to enhance the reliability and efficiency of the motor controller. The selection of appropriate capacitors, inductors, and heat sinks will play a significant role in the overall performance and longevity of the device. Furthermore, implementing feedback mechanisms, such as current sensing and speed feedback loops, can improve the control accuracy and responsiveness of the motor speed controller.Controlling the speed of three phase ac motor is done by controlling the frequency of the power line supply, since the motor is synchronized with the line frequency. Three phase ac motor speed controller is actually nothing more than three phase sine wave power inverter with variable frequency.

The three phase power inverter is a complex circuit, but fortunately there is an integrated circuit chip for this purpose. This is the figure of the circuit; For the final motor driver circuit, you can see the component values are shown only for OB2 channel, but the others are similar. This 3 phase ac motor controller use optical isolation, so you must be careful in designing the layout, to make a clear separation between low and high voltage network.

This separation is useful for minimizing the risk of hazardouz electrical shock. 🔗 External reference