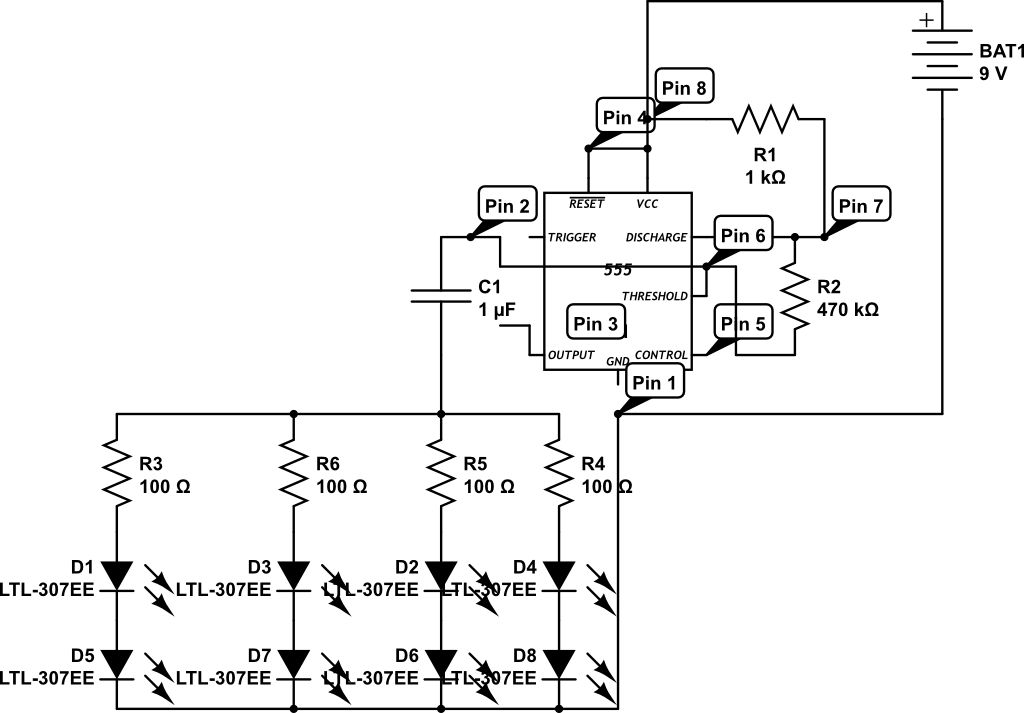

555 circuit for 8 leds flashing

LEDs are rated for a continuous current of only 30 mA, while this circuit operates them at approximately 50 mA. Although this is acceptable for low duty cycles with short pulses, the intended design has a high duty cycle. This could pose a problem as the circuit operates at the maximum capacity of the output pin (200 mA). It is advisable to use a transistor to drive the LED current. The selected resistors will keep the LEDs on for about half the time, resulting in a flash rate of slightly more than once per second. Therefore, it is recommended to use a 1 MOhm resistor instead of the current 470 KOhm to reduce the pulse rate. Additionally, placing a diode across the resistor allows the capacitor to charge only through the 1K resistor, leading to a quick flash followed by a longer off period as the capacitor discharges through the 1 MOhm resistor. Experimentation with resistor values is encouraged to achieve the desired flash rate.

The circuit described involves the use of light-emitting diodes (LEDs) operating under specific current ratings. Standard LEDs typically have a maximum continuous current rating of 30 mA. In this design, the LEDs are driven at a higher current of approximately 50 mA, which is acceptable for low duty cycle applications but may lead to overheating or damage in high duty cycle scenarios. The output pin of the driving circuit is rated for a maximum output of 200 mA, which further complicates the design since operating close to this limit can lead to reliability issues.

To mitigate the risks associated with high current draw from the output pin, it is recommended to incorporate a transistor switch. The transistor will allow for higher current capacity while protecting the microcontroller or driving circuit from excessive load. The base of the transistor can be connected to the output pin, allowing it to control the LED current more safely.

The choice of resistors in this circuit is crucial. The original design uses a 470 KOhm resistor, which results in the LEDs being illuminated for approximately half the time, creating a flashing effect at a rate of slightly more than once per second. However, to achieve a more desirable flash rate, a 1 MOhm resistor is suggested. This change will slow down the charging time of the capacitor, thus controlling the blink rate of the LEDs more effectively.

Incorporating a diode across the resistor is also beneficial. This configuration allows the capacitor to charge rapidly through the 1K resistor while enabling a slower discharge through the 1 MOhm resistor. The result is a quick flash followed by an extended off period, which can be adjusted by experimenting with different resistor values. This flexibility allows for fine-tuning to achieve the desired visual effect of the LED flashing sequence.

Overall, careful consideration of component ratings and circuit design is essential to ensure the longevity and reliability of the LED circuit while achieving the intended operational characteristics.LEDs are rated at only 30 mA continuous, whereas this circuit runs them at around 50 mA. Not a problem for a low duty cycle with short pulses, but this circuit as you intend has a high duty cycle. Where you might run into a problem is that you`re right at the maximum capacity of the output pin (200 mA).

You might want to have the output pin drive a transistor to source the LED current. With the resistors you`ve selected, the LEDs will be on about half the time, and flashing a bit over once per second. This is why Rick recommends something more like a 1MOhm resistor, to slow the pulse rate down. What I would recommend is that you replace the 470 KOhm with a 1 MOhm and then put a diode across it.

This allows the cap to charge only through the 1K resistor, resulting in a very quick flash, followed by a relatively longer off period as the capacitor is forced to discharge through the 1M resistor. You should, of course, play around with the resistor values until you find a flash that is what you want,

🔗 External reference

The circuit described involves the use of light-emitting diodes (LEDs) operating under specific current ratings. Standard LEDs typically have a maximum continuous current rating of 30 mA. In this design, the LEDs are driven at a higher current of approximately 50 mA, which is acceptable for low duty cycle applications but may lead to overheating or damage in high duty cycle scenarios. The output pin of the driving circuit is rated for a maximum output of 200 mA, which further complicates the design since operating close to this limit can lead to reliability issues.

To mitigate the risks associated with high current draw from the output pin, it is recommended to incorporate a transistor switch. The transistor will allow for higher current capacity while protecting the microcontroller or driving circuit from excessive load. The base of the transistor can be connected to the output pin, allowing it to control the LED current more safely.

The choice of resistors in this circuit is crucial. The original design uses a 470 KOhm resistor, which results in the LEDs being illuminated for approximately half the time, creating a flashing effect at a rate of slightly more than once per second. However, to achieve a more desirable flash rate, a 1 MOhm resistor is suggested. This change will slow down the charging time of the capacitor, thus controlling the blink rate of the LEDs more effectively.

Incorporating a diode across the resistor is also beneficial. This configuration allows the capacitor to charge rapidly through the 1K resistor while enabling a slower discharge through the 1 MOhm resistor. The result is a quick flash followed by an extended off period, which can be adjusted by experimenting with different resistor values. This flexibility allows for fine-tuning to achieve the desired visual effect of the LED flashing sequence.

Overall, careful consideration of component ratings and circuit design is essential to ensure the longevity and reliability of the LED circuit while achieving the intended operational characteristics.LEDs are rated at only 30 mA continuous, whereas this circuit runs them at around 50 mA. Not a problem for a low duty cycle with short pulses, but this circuit as you intend has a high duty cycle. Where you might run into a problem is that you`re right at the maximum capacity of the output pin (200 mA).

You might want to have the output pin drive a transistor to source the LED current. With the resistors you`ve selected, the LEDs will be on about half the time, and flashing a bit over once per second. This is why Rick recommends something more like a 1MOhm resistor, to slow the pulse rate down. What I would recommend is that you replace the 470 KOhm with a 1 MOhm and then put a diode across it.

This allows the cap to charge only through the 1K resistor, resulting in a very quick flash, followed by a relatively longer off period as the capacitor is forced to discharge through the 1M resistor. You should, of course, play around with the resistor values until you find a flash that is what you want,

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713