A relay control circuit

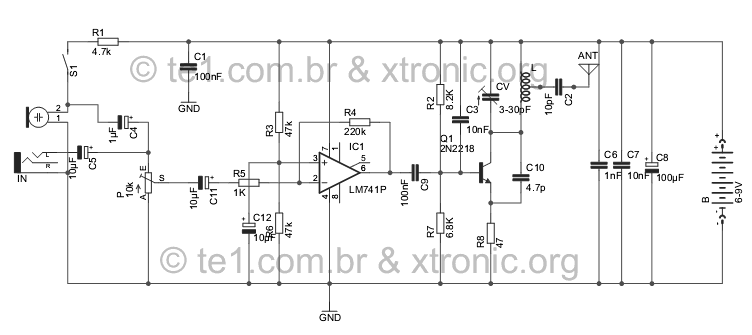

A relay control circuit is illustrated, which is commonly found in microwave switches. This circuit facilitates the operation of various components such as the power supply switch, electric fans, light bulbs, food turntables, and timers. The relay control signal circuit primarily operates with strong signals, typically around 22V. Directly controlling these components with a transistor switch requires high-voltage transistors capable of withstanding 220V, which increases production costs and safety risks. High-voltage transistors necessitate the use of heat sinks, which can become charged and pose safety hazards. In contrast, relays allow for low-voltage signals to control high-voltage signals safely. The circuit diagram shows that the relay coil acts as an electromagnet; when energized, it opens or closes contacts. The relay coil voltage is isolated, ensuring a safe control circuit free from high voltage. The left and right sides of the circuit diagram exhibit similar structures but utilize different types of transistors; the left employs NPN transistors, while the right employs PNP transistors. The polarity of these transistors differs; in the PNP configuration, the emitter must be connected to ground to operate the relay. In the NPN configuration, the control signal is high when the transistor is off, and low when the transistor is on, allowing current to flow through the relay to control its contacts. The PNP transistor circuit requires reversed polarity protection diodes to account for the induced electromotive force generated by the relay coil, which changes polarity. Attention must be paid to the transistor models, control signals, and voltage polarity protection diodes, as they differ across the circuit.

A relay control circuit is essential for managing high-power devices within microwave ovens and similar applications. The circuit operates by using a relay to isolate low-voltage control signals from high-voltage loads. The relay coil, when energized by a low-voltage signal, generates a magnetic field that actuates the relay contacts, allowing current to flow to the connected load. This method enhances safety by preventing high voltage from reaching sensitive control components.

The circuit can be constructed using either NPN or PNP transistors. In the NPN configuration, the transistor conducts when the base receives a sufficient control voltage, allowing current to pass from the collector to the emitter, thus energizing the relay coil. Conversely, in the PNP configuration, the transistor conducts when the base is pulled low relative to the emitter, allowing the current to flow from the emitter to the collector. This fundamental difference in operation necessitates careful consideration of the control signal applied to each type of transistor.

Protection diodes are crucial in this design, particularly when dealing with inductive loads such as relay coils. When the relay is de-energized, the collapsing magnetic field can generate a back EMF, potentially damaging the transistor. Therefore, a diode is placed in reverse bias across the relay coil to safely dissipate this induced voltage, ensuring the longevity and reliability of the circuit.

The schematic should clearly indicate the connections for each transistor type, the relay coil, and the associated protection diodes. Proper labeling of components and voltage levels will aid in understanding the operational characteristics of the circuit. This relay control circuit exemplifies an effective solution for controlling high-power devices while maintaining safety and minimizing component costs.A relay control circuit It shows the relay control circuit. There are many in the microwave switches, such as the power supply switch is turned on can be achieved, switch off p rotection can be achieved. In the microwave oven there are many components to be controlled, such as electric fans, light bulbs, food turntable, timers. In the relay control signal circuit which mostly belong to a strong signal, many of which are 22V of voltage.

If the direct control using a transistor switch, then the transistor must withstand high voltage 220 V, which must use high voltage transistors and power transistors. This circuit will not only increase production costs, but also security overhaul has also been guaranteed.

Because the high voltage of the transistor, current, it will inevitably need to add heat sink, the heat sink may be charged, the three legs of the transistor may also be charged, so it is very unsafe. Relays can be achieved by using low-voltage signal to control the high signal. It can be seen from the figure, in a relay coil is made of electromagnet, when energized electromagnet would be action, which led to open contacts close.

And contacts on the relay coil voltage is isolated, the control relay coil circuit does not have the high-pressure, very safe. Left and right in the figure on the circuit structure is the same, but uses different control transistor, using the left side of the circuit are NPN type transistors, the right side of the circuit using a PNP type transistor.

Polarity PNP transistor and the NPN transistor is not the same, so the use of PNP transistor circuit, the voltage to be applied to the emitter of PNP transistor, connected to the ground to relay this end. House of the drive signal also (NPN type transistor circuit) stated before the contrary, if the transistor is turned off, the circuit control signal is high, if the control signal appears low.

Transistor will be turned on, and then will flow through the relay 1V to control the turn on or off the relay contacts. Circuit in the connection of PNP transistors, polarity protection diodes designed also be reversed, because the coil generates an induced electromotive force polarity is changed, and when looking at the circuit diagram, pay attention to the model of the transistor.

Transistor models, the control signal, the voltage polarity protection diodes are not the same.

A relay control circuit is essential for managing high-power devices within microwave ovens and similar applications. The circuit operates by using a relay to isolate low-voltage control signals from high-voltage loads. The relay coil, when energized by a low-voltage signal, generates a magnetic field that actuates the relay contacts, allowing current to flow to the connected load. This method enhances safety by preventing high voltage from reaching sensitive control components.

The circuit can be constructed using either NPN or PNP transistors. In the NPN configuration, the transistor conducts when the base receives a sufficient control voltage, allowing current to pass from the collector to the emitter, thus energizing the relay coil. Conversely, in the PNP configuration, the transistor conducts when the base is pulled low relative to the emitter, allowing the current to flow from the emitter to the collector. This fundamental difference in operation necessitates careful consideration of the control signal applied to each type of transistor.

Protection diodes are crucial in this design, particularly when dealing with inductive loads such as relay coils. When the relay is de-energized, the collapsing magnetic field can generate a back EMF, potentially damaging the transistor. Therefore, a diode is placed in reverse bias across the relay coil to safely dissipate this induced voltage, ensuring the longevity and reliability of the circuit.

The schematic should clearly indicate the connections for each transistor type, the relay coil, and the associated protection diodes. Proper labeling of components and voltage levels will aid in understanding the operational characteristics of the circuit. This relay control circuit exemplifies an effective solution for controlling high-power devices while maintaining safety and minimizing component costs.A relay control circuit It shows the relay control circuit. There are many in the microwave switches, such as the power supply switch is turned on can be achieved, switch off p rotection can be achieved. In the microwave oven there are many components to be controlled, such as electric fans, light bulbs, food turntable, timers. In the relay control signal circuit which mostly belong to a strong signal, many of which are 22V of voltage.

If the direct control using a transistor switch, then the transistor must withstand high voltage 220 V, which must use high voltage transistors and power transistors. This circuit will not only increase production costs, but also security overhaul has also been guaranteed.

Because the high voltage of the transistor, current, it will inevitably need to add heat sink, the heat sink may be charged, the three legs of the transistor may also be charged, so it is very unsafe. Relays can be achieved by using low-voltage signal to control the high signal. It can be seen from the figure, in a relay coil is made of electromagnet, when energized electromagnet would be action, which led to open contacts close.

And contacts on the relay coil voltage is isolated, the control relay coil circuit does not have the high-pressure, very safe. Left and right in the figure on the circuit structure is the same, but uses different control transistor, using the left side of the circuit are NPN type transistors, the right side of the circuit using a PNP type transistor.

Polarity PNP transistor and the NPN transistor is not the same, so the use of PNP transistor circuit, the voltage to be applied to the emitter of PNP transistor, connected to the ground to relay this end. House of the drive signal also (NPN type transistor circuit) stated before the contrary, if the transistor is turned off, the circuit control signal is high, if the control signal appears low.

Transistor will be turned on, and then will flow through the relay 1V to control the turn on or off the relay contacts. Circuit in the connection of PNP transistors, polarity protection diodes designed also be reversed, because the coil generates an induced electromotive force polarity is changed, and when looking at the circuit diagram, pay attention to the model of the transistor.

Transistor models, the control signal, the voltage polarity protection diodes are not the same.