Alcohol used to monitor gas concentration gas sensor circuit diagram

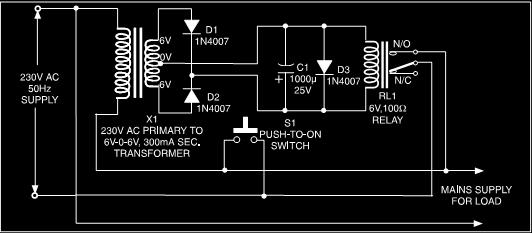

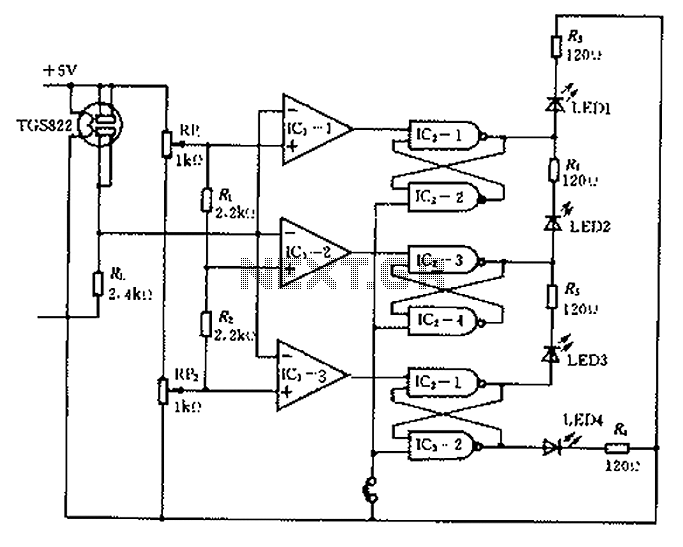

Ceramic gas sensors can be utilized to analyze the content of alcohol vapor. With the appropriate sensor circuit, it is possible to detect blood alcohol content. The operating principle is straightforward: if blood alcohol content is present in a certain proportion, it will evaporate into the air, and the higher the blood alcohol concentration, the greater the divergence ratio into the air. When air is blown over the sensor containing alcohol, the sensor's resistance will change in response to the alcohol concentration, and this change can be measured using a suitable circuit. A circuit diagram is illustrated in Figure 8-24. The TGS 822 gas sensor, manufactured by Figaro, is utilized in this application. The circuit is powered by a regulated +5V DC power supply. The sensor output voltage is fed through a load resistor to the input of three interconnected operational amplifiers configured as comparators. Resistors R1 and R2 serve as a reference voltage generator, with the upper limit reference voltage set by variable resistor RP1 and the lower limit set by RP2. Upon powering the circuit and pressing the reset button, the system enters a logic low state, causing LEDs LED1 to LED3 to remain off. When alcohol vapor interacts with the sensor, the voltage drop across the load resistor begins to increase. The output from the comparators triggers the corresponding LEDs to illuminate. If the alcohol vapor exposure ceases, the voltage across the load resistor decreases slowly. Pressing the reset button returns the system to its initial state. To enhance accuracy and compensate for the effects of temperature and humidity on sensor characteristics, it is advisable to incorporate a thermistor and/or humidity sensor circuit for compensation.

Ceramic gas sensors, such as the TGS 822, operate on the principle of resistive change in response to the presence of specific gases, including alcohol vapor. The sensor consists of a ceramic substrate coated with a sensitive material that reacts to alcohol molecules in the air. As the concentration of alcohol vapor increases, the resistance of the sensor decreases, allowing for the detection of varying levels of blood alcohol content.

The circuit design incorporates a regulated +5V DC power supply to ensure stable operation of the sensor and associated components. The output from the sensor is connected to a load resistor, which converts the change in sensor resistance into a measurable voltage change. This voltage is then processed by three operational amplifiers configured as comparators. These comparators compare the sensor output against predefined reference voltages established by resistors R1, R2, and the variable resistors RP1 and RP2.

The use of variable resistors allows for fine-tuning of the upper and lower thresholds for alcohol detection, providing flexibility in the circuit's sensitivity. The comparators provide a digital output that can be used to trigger visual indicators, such as LEDs, which provide immediate feedback to the user regarding the presence of alcohol vapor.

To address potential variations in sensor performance due to environmental factors such as temperature and humidity, the inclusion of a thermistor and/or humidity sensor is recommended. These additional components can be integrated into the circuit to dynamically adjust the reference voltages, ensuring accurate readings under varying conditions. This compensation is crucial for applications where precise blood alcohol content measurements are required, such as in breathalyzer devices.

In summary, the described circuit effectively utilizes a ceramic gas sensor to detect alcohol vapor, with a robust design that incorporates operational amplifiers for signal processing and provisions for environmental compensation to enhance measurement accuracy. Ceramic gas sensors can also be used to analyze the content of alcohol vapor. With the corresponding sensor circuit can be detected with a blood alcohol content. Its working pr inciple is very simple, if the blood alcohol content contained in a certain proportion, then it will certainly diverge into the air, the higher the blood alcohol concentration in the air diverging ratio is greater. If the air is blowing sensor contains a concentration of alcohol, the resistance of the sensor will react with a corresponding change in the alcohol concentration, the change can be a suitable measuring circuit identification.

Such a circuit is shown in Figure 8-24. TGS 822 gas sensor used is manufactured by Figaro. Circuit from the regulated DC power supply + 5V supply. The sensor output voltage of the inverter load resistor load to the input of three operational amplifiers, comparators into three interconnected. In fact, the resistors R1 and R2 are the reference voltage generator. Upper limit reference voltage set by the variable resistor RP1, RP2 is set by the lower limit. After power on, and press the reset button and the trigger to enter the logic O state. In this case, the light emitting diode LED1 ~ LED3 does not emit light. When alcohol vapor acting on the sensor, the voltage drop across the load resistor begins to change (gradually increased).

The results of these discrete comparators work order results in a corresponding trigger open, so they are in contact with the LED lights. If the alcohol vapor sensor to stop action, then the voltage on the load resistance will decline slowly.

After pressing the reset button, back to the initial state. In order to compensate for the effects of temperature and humidity on the sensor characteristics, and in order to obtain greater accuracy, we recommend using a thermistor and (or) humidity sensor circuit to compensate.

Ceramic gas sensors, such as the TGS 822, operate on the principle of resistive change in response to the presence of specific gases, including alcohol vapor. The sensor consists of a ceramic substrate coated with a sensitive material that reacts to alcohol molecules in the air. As the concentration of alcohol vapor increases, the resistance of the sensor decreases, allowing for the detection of varying levels of blood alcohol content.

The circuit design incorporates a regulated +5V DC power supply to ensure stable operation of the sensor and associated components. The output from the sensor is connected to a load resistor, which converts the change in sensor resistance into a measurable voltage change. This voltage is then processed by three operational amplifiers configured as comparators. These comparators compare the sensor output against predefined reference voltages established by resistors R1, R2, and the variable resistors RP1 and RP2.

The use of variable resistors allows for fine-tuning of the upper and lower thresholds for alcohol detection, providing flexibility in the circuit's sensitivity. The comparators provide a digital output that can be used to trigger visual indicators, such as LEDs, which provide immediate feedback to the user regarding the presence of alcohol vapor.

To address potential variations in sensor performance due to environmental factors such as temperature and humidity, the inclusion of a thermistor and/or humidity sensor is recommended. These additional components can be integrated into the circuit to dynamically adjust the reference voltages, ensuring accurate readings under varying conditions. This compensation is crucial for applications where precise blood alcohol content measurements are required, such as in breathalyzer devices.

In summary, the described circuit effectively utilizes a ceramic gas sensor to detect alcohol vapor, with a robust design that incorporates operational amplifiers for signal processing and provisions for environmental compensation to enhance measurement accuracy. Ceramic gas sensors can also be used to analyze the content of alcohol vapor. With the corresponding sensor circuit can be detected with a blood alcohol content. Its working pr inciple is very simple, if the blood alcohol content contained in a certain proportion, then it will certainly diverge into the air, the higher the blood alcohol concentration in the air diverging ratio is greater. If the air is blowing sensor contains a concentration of alcohol, the resistance of the sensor will react with a corresponding change in the alcohol concentration, the change can be a suitable measuring circuit identification.

Such a circuit is shown in Figure 8-24. TGS 822 gas sensor used is manufactured by Figaro. Circuit from the regulated DC power supply + 5V supply. The sensor output voltage of the inverter load resistor load to the input of three operational amplifiers, comparators into three interconnected. In fact, the resistors R1 and R2 are the reference voltage generator. Upper limit reference voltage set by the variable resistor RP1, RP2 is set by the lower limit. After power on, and press the reset button and the trigger to enter the logic O state. In this case, the light emitting diode LED1 ~ LED3 does not emit light. When alcohol vapor acting on the sensor, the voltage drop across the load resistor begins to change (gradually increased).

The results of these discrete comparators work order results in a corresponding trigger open, so they are in contact with the LED lights. If the alcohol vapor sensor to stop action, then the voltage on the load resistance will decline slowly.

After pressing the reset button, back to the initial state. In order to compensate for the effects of temperature and humidity on the sensor characteristics, and in order to obtain greater accuracy, we recommend using a thermistor and (or) humidity sensor circuit to compensate.