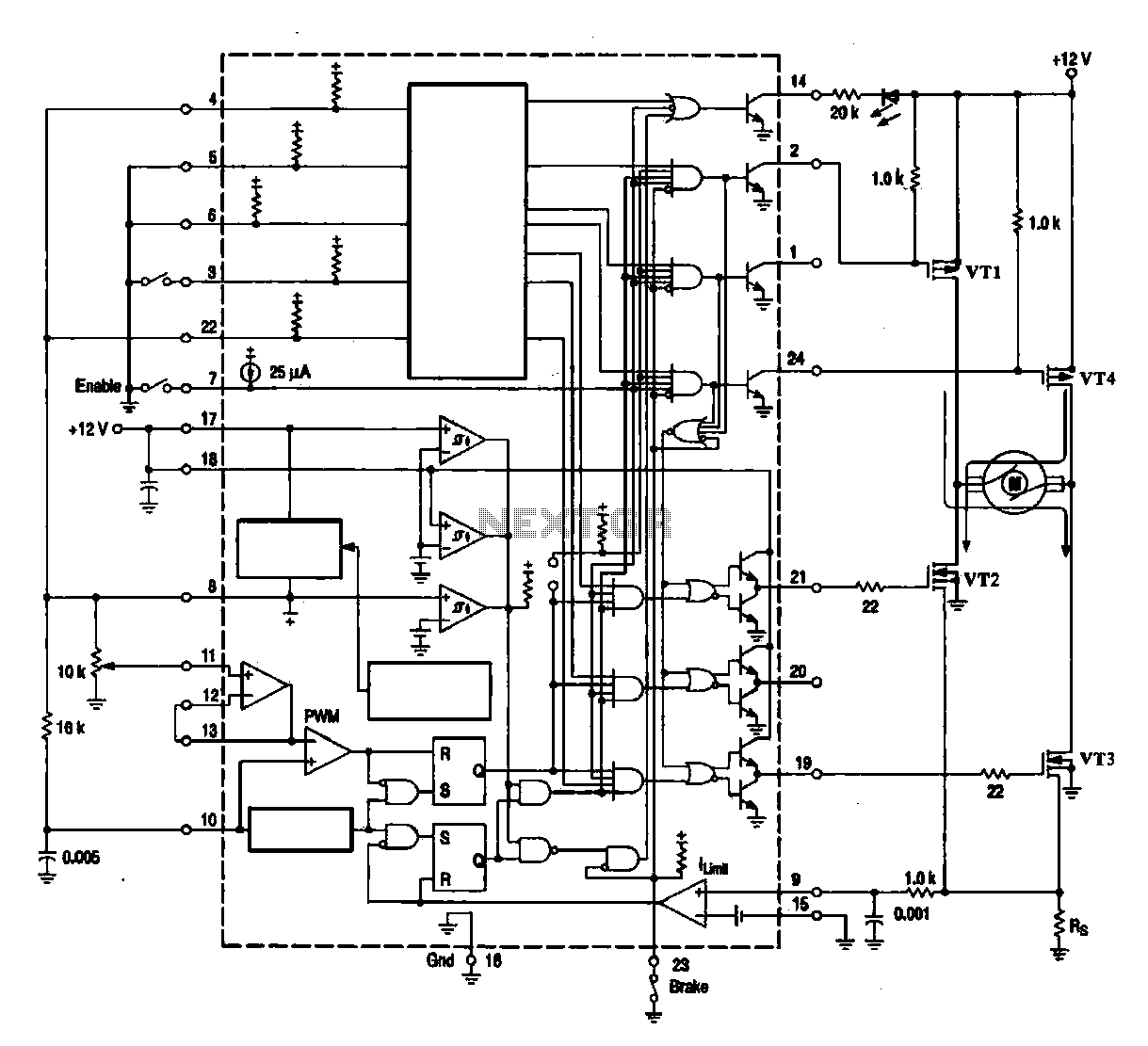

DC brush motor driver circuit diagram

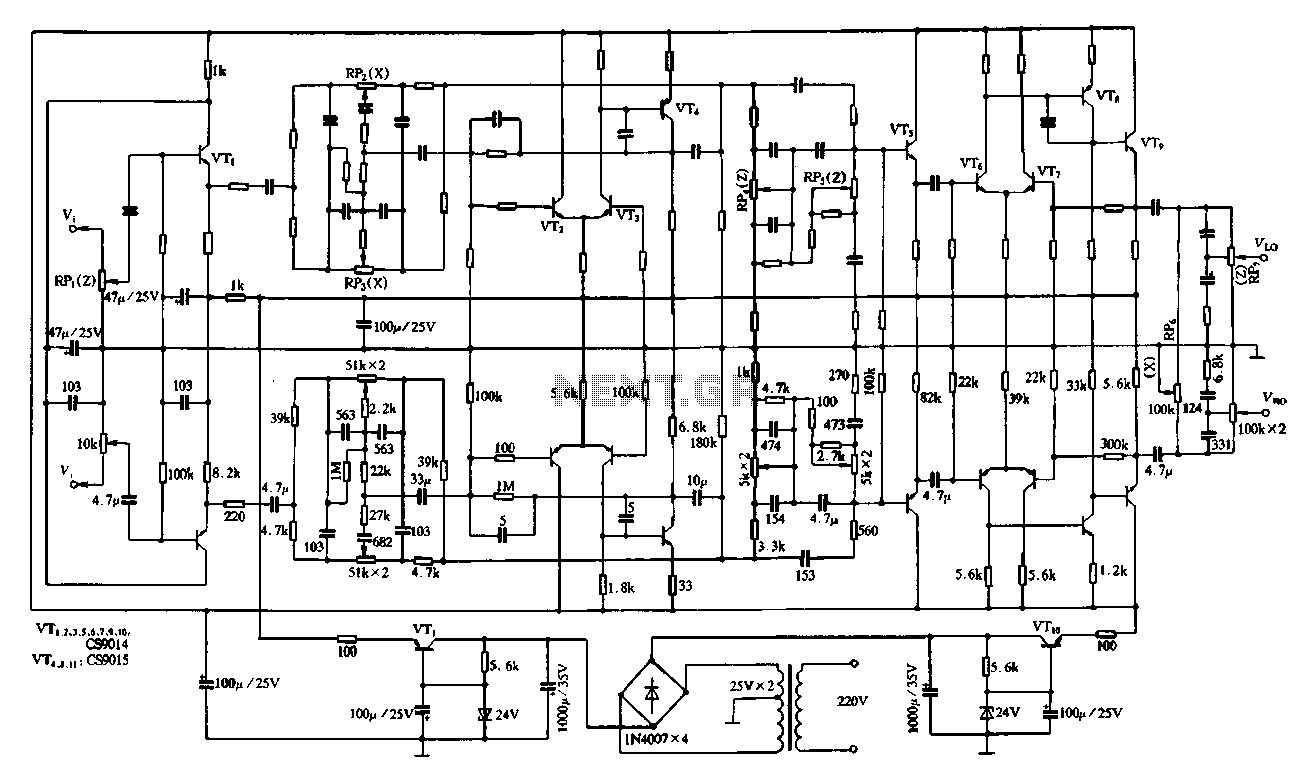

A DC brush motor driver circuit diagram utilizing the MC33035 chip is presented, illustrating a typical configuration for driving a straight DC brush motor. The circuit incorporates a field-effect transistor (FET) bridge driver setup. When transistor VT3 is activated, the motor rotates in the forward direction; conversely, when transistors VT2 and VT4 are activated, the motor rotates in the reverse direction. The drive signal is generated by the MC33035 chip.

The described DC brush motor driver circuit leverages the MC33035 integrated circuit, which is specifically designed for controlling DC motors in various applications. This chip provides the necessary drive signals to control the operation of the motor efficiently. The configuration includes a bridge driver circuit formed by field-effect transistors (FETs), which allows for bidirectional control of the motor.

In the forward rotation mode, the activation of transistor VT3 allows current to flow through the motor in one direction, resulting in forward movement. The reverse rotation is achieved by turning on transistors VT2 and VT4 simultaneously, which reverses the current flow through the motor, enabling it to rotate in the opposite direction.

This circuit design is particularly advantageous for applications requiring precise control over motor direction and speed. The MC33035 chip simplifies the control logic by integrating the necessary components into a single package, reducing the complexity of the circuit. Additionally, the use of FETs in the bridge configuration enhances the efficiency of the circuit by minimizing power losses and providing faster switching times, which is critical for applications demanding rapid changes in motor direction.

Overall, this DC brush motor driver circuit exhibits a robust design suitable for various automation and robotics applications, ensuring reliable performance and ease of integration into larger systems.DC brush motor driver circuit diagram MC33035 chip using a straight debate brush motor driving circuit ring shows a typical DC brush motor driver circuit diagram. 4 field effec t transistor bridge driver circuit, when the VTI, when the transistor VT3 conduction, the forward rotation of the drive motor; when VT2, VT4 when the transistor is turned on, the reverse rotation of the drive motor. Drive signal generated by the chip number MC33035.

The described DC brush motor driver circuit leverages the MC33035 integrated circuit, which is specifically designed for controlling DC motors in various applications. This chip provides the necessary drive signals to control the operation of the motor efficiently. The configuration includes a bridge driver circuit formed by field-effect transistors (FETs), which allows for bidirectional control of the motor.

In the forward rotation mode, the activation of transistor VT3 allows current to flow through the motor in one direction, resulting in forward movement. The reverse rotation is achieved by turning on transistors VT2 and VT4 simultaneously, which reverses the current flow through the motor, enabling it to rotate in the opposite direction.

This circuit design is particularly advantageous for applications requiring precise control over motor direction and speed. The MC33035 chip simplifies the control logic by integrating the necessary components into a single package, reducing the complexity of the circuit. Additionally, the use of FETs in the bridge configuration enhances the efficiency of the circuit by minimizing power losses and providing faster switching times, which is critical for applications demanding rapid changes in motor direction.

Overall, this DC brush motor driver circuit exhibits a robust design suitable for various automation and robotics applications, ensuring reliable performance and ease of integration into larger systems.DC brush motor driver circuit diagram MC33035 chip using a straight debate brush motor driving circuit ring shows a typical DC brush motor driver circuit diagram. 4 field effec t transistor bridge driver circuit, when the VTI, when the transistor VT3 conduction, the forward rotation of the drive motor; when VT2, VT4 when the transistor is turned on, the reverse rotation of the drive motor. Drive signal generated by the chip number MC33035.