Battery Tester

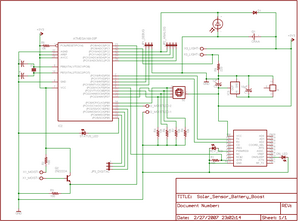

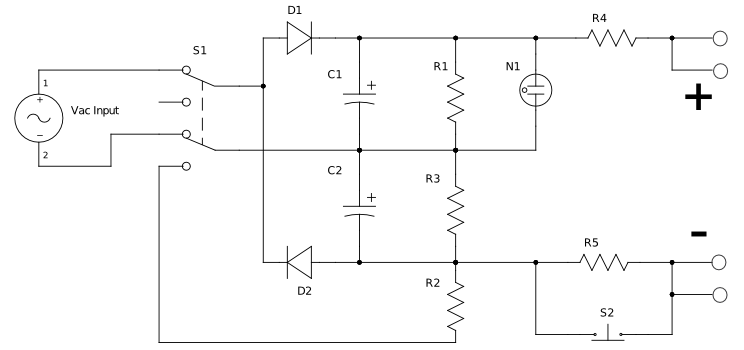

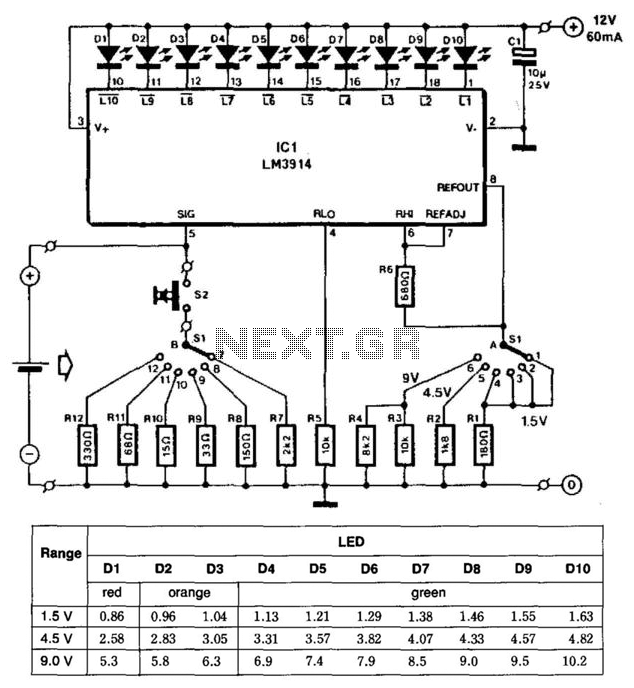

This battery tester utilizes an LM3914 bar-graph driver integrated circuit (IC). Switch SI selects the load on the battery being tested and programs the voltage range. Switch S2 applies the load to the battery under test. A table provides the calibration factors for the tester. LEDs D1 through D10 serve as indicators.

The battery tester circuit is designed to evaluate the performance of batteries by providing a visual representation of voltage levels through a bar graph display. The LM3914 IC is a versatile component that drives multiple LEDs based on the input voltage, allowing for a clear indication of the battery's state.

In this design, switch SI is responsible for selecting the appropriate load for the battery under test, which can be adjusted according to the battery's specifications. This ensures that the tester can accommodate various battery types and voltages. The voltage range can be programmed to match the specific battery being tested, enhancing the accuracy of the results.

Switch S2 is employed to apply the selected load to the battery. This step is crucial as it simulates real-world conditions under which the battery operates, allowing for a more accurate assessment of its performance. The tester's calibration factors, provided in a table, enable users to translate the LED readings into meaningful voltage values. This calibration ensures that the tester delivers precise measurements regardless of the battery type.

The LED indicators D1 through D10 are arranged in a bar graph format, providing a visual cue of the battery's voltage level. Each LED corresponds to a specific voltage range, with the illumination of multiple LEDs indicating a higher voltage. This intuitive display allows users to quickly assess the battery's condition without needing complex measurement tools.

Overall, the design of this battery tester combines functionality and ease of use, making it a valuable tool for assessing battery health in various applications. This battery tester makes use of an LM3914 bar-graph driver IC. SI selects load on battery under test and programs the volta ge range. S2 loads the battery under test. The table gives the calibration factors for the tester. LEDs Dl through D10 are used as indicators.

The battery tester circuit is designed to evaluate the performance of batteries by providing a visual representation of voltage levels through a bar graph display. The LM3914 IC is a versatile component that drives multiple LEDs based on the input voltage, allowing for a clear indication of the battery's state.

In this design, switch SI is responsible for selecting the appropriate load for the battery under test, which can be adjusted according to the battery's specifications. This ensures that the tester can accommodate various battery types and voltages. The voltage range can be programmed to match the specific battery being tested, enhancing the accuracy of the results.

Switch S2 is employed to apply the selected load to the battery. This step is crucial as it simulates real-world conditions under which the battery operates, allowing for a more accurate assessment of its performance. The tester's calibration factors, provided in a table, enable users to translate the LED readings into meaningful voltage values. This calibration ensures that the tester delivers precise measurements regardless of the battery type.

The LED indicators D1 through D10 are arranged in a bar graph format, providing a visual cue of the battery's voltage level. Each LED corresponds to a specific voltage range, with the illumination of multiple LEDs indicating a higher voltage. This intuitive display allows users to quickly assess the battery's condition without needing complex measurement tools.

Overall, the design of this battery tester combines functionality and ease of use, making it a valuable tool for assessing battery health in various applications. This battery tester makes use of an LM3914 bar-graph driver IC. SI selects load on battery under test and programs the volta ge range. S2 loads the battery under test. The table gives the calibration factors for the tester. LEDs Dl through D10 are used as indicators.