BFO metal Detector Circuit with IC 4093

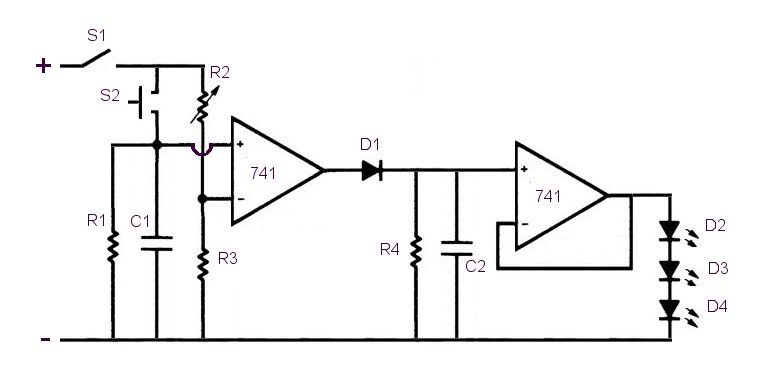

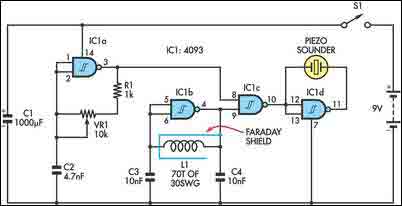

The circuit incorporates two oscillators, both operating at about 40kHz. The first, IC1a, is a standard CMOS oscillator with its frequency adjustable via VR1. The frequency of the second, IC1b, is highly dependent on the inductance of coil L1, so that its frequency shifts in the presence of metal. L1 is 70 turns of 0.315mm enamelled copper wire wound on a 120mm diameter former. More: The two oscillator signals are mixed through IC1c, to create a beat note. IC1d and IC1c drive the piezo sounder in push-pull fashion, thereby boosting the output. Unlike many other metal locators of its kind, this locator is particularly easy to tune. Around the midpoint setting of VR1, there will be a loud beat frequency with a null point in the middle. The locator needs to be tuned to a low frequency beat note to one or the other side of this null point. Depending on which side is chosen, it will be sensitive to either ferrous or non-ferrous metals. Besides detecting objects under the ground, the circuit could serve well as a pipe locator.

The circuit design features two oscillators, designated as IC1a and IC1b, both operating at an approximate frequency of 40 kHz. IC1a functions as a standard CMOS oscillator, with its frequency being adjustable through a variable resistor, VR1. This adjustability allows for fine-tuning of the oscillation frequency, which is crucial for optimal performance in metal detection applications. The second oscillator, IC1b, operates with a frequency that is influenced by the inductance of an inductor, L1. This inductor is constructed from 70 turns of 0.315 mm enamelled copper wire, wound around a former with a diameter of 120 mm. The inductance of L1 is sensitive to nearby metallic objects, causing a shift in the oscillation frequency of IC1b when such objects are detected.

The outputs from both oscillators are combined using IC1c, which serves as a mixer to generate a beat frequency. This beat frequency is essential for the operation of the circuit, as it provides an audible signal that indicates the presence of metal. The piezo sounder is driven in a push-pull configuration by the outputs of IC1c and IC1d, which enhances the sound output, making the detection signal more pronounced.

Tuning the circuit is simplified due to its design, allowing the user to adjust VR1 to find a loud beat frequency at a midpoint setting. This midpoint also defines a null point, where the output signal is minimized. The user can adjust the circuit to either side of this null point, enabling sensitivity to specific types of metals—either ferrous or non-ferrous. This flexibility makes the circuit not only effective for detecting buried metallic objects but also suitable for locating underground pipes. The design's adaptability and ease of tuning contribute to its effectiveness in various metal detection scenarios.The circuit incorporates two oscillators, both operating at about 40kHz. The first, IC1a, is a standard CMOS oscillator with its frequency adjustable via VR1. The frequency of the second, IC1b, is highly dependent on the inductance of coil L1, so that its frequency shifts in the presence of metal. L1 is 70 turns of 0.315mm enamelled copper wire wound on a 120mm diameter former. The two oscillator signals are mixed through IC1c, to create a beat note. IC1d and IC1c drive the piezo sounder in push-pull fashion, thereby boosting the output. Unlike many other metal locators of its kind, this locator is particularly easy to tune. Around the midpoint setting of VR1, there will be a loud beat frequency with a null point in the middle. The locator needs to be tuned to a low frequency beat note to one or the other side of this null point.

Depending on which side is chosen, it will be sensitive to either ferrous or non-ferrous metals. Besides detecting objects under the ground, the circuit could serve well as a pipe locator. 🔗 External reference

The circuit design features two oscillators, designated as IC1a and IC1b, both operating at an approximate frequency of 40 kHz. IC1a functions as a standard CMOS oscillator, with its frequency being adjustable through a variable resistor, VR1. This adjustability allows for fine-tuning of the oscillation frequency, which is crucial for optimal performance in metal detection applications. The second oscillator, IC1b, operates with a frequency that is influenced by the inductance of an inductor, L1. This inductor is constructed from 70 turns of 0.315 mm enamelled copper wire, wound around a former with a diameter of 120 mm. The inductance of L1 is sensitive to nearby metallic objects, causing a shift in the oscillation frequency of IC1b when such objects are detected.

The outputs from both oscillators are combined using IC1c, which serves as a mixer to generate a beat frequency. This beat frequency is essential for the operation of the circuit, as it provides an audible signal that indicates the presence of metal. The piezo sounder is driven in a push-pull configuration by the outputs of IC1c and IC1d, which enhances the sound output, making the detection signal more pronounced.

Tuning the circuit is simplified due to its design, allowing the user to adjust VR1 to find a loud beat frequency at a midpoint setting. This midpoint also defines a null point, where the output signal is minimized. The user can adjust the circuit to either side of this null point, enabling sensitivity to specific types of metals—either ferrous or non-ferrous. This flexibility makes the circuit not only effective for detecting buried metallic objects but also suitable for locating underground pipes. The design's adaptability and ease of tuning contribute to its effectiveness in various metal detection scenarios.The circuit incorporates two oscillators, both operating at about 40kHz. The first, IC1a, is a standard CMOS oscillator with its frequency adjustable via VR1. The frequency of the second, IC1b, is highly dependent on the inductance of coil L1, so that its frequency shifts in the presence of metal. L1 is 70 turns of 0.315mm enamelled copper wire wound on a 120mm diameter former. The two oscillator signals are mixed through IC1c, to create a beat note. IC1d and IC1c drive the piezo sounder in push-pull fashion, thereby boosting the output. Unlike many other metal locators of its kind, this locator is particularly easy to tune. Around the midpoint setting of VR1, there will be a loud beat frequency with a null point in the middle. The locator needs to be tuned to a low frequency beat note to one or the other side of this null point.

Depending on which side is chosen, it will be sensitive to either ferrous or non-ferrous metals. Besides detecting objects under the ground, the circuit could serve well as a pipe locator. 🔗 External reference