build solid state scrtriac controlled

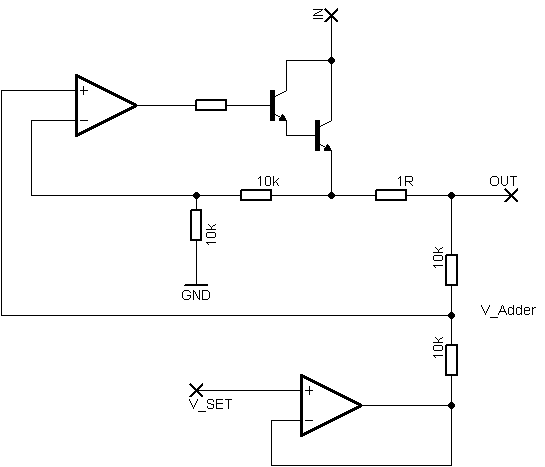

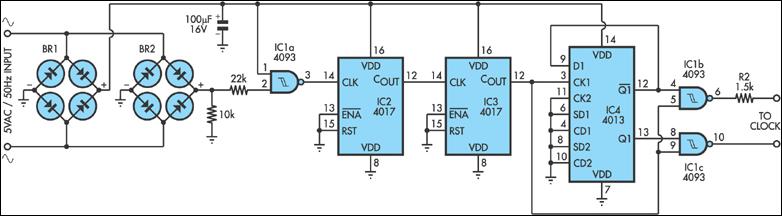

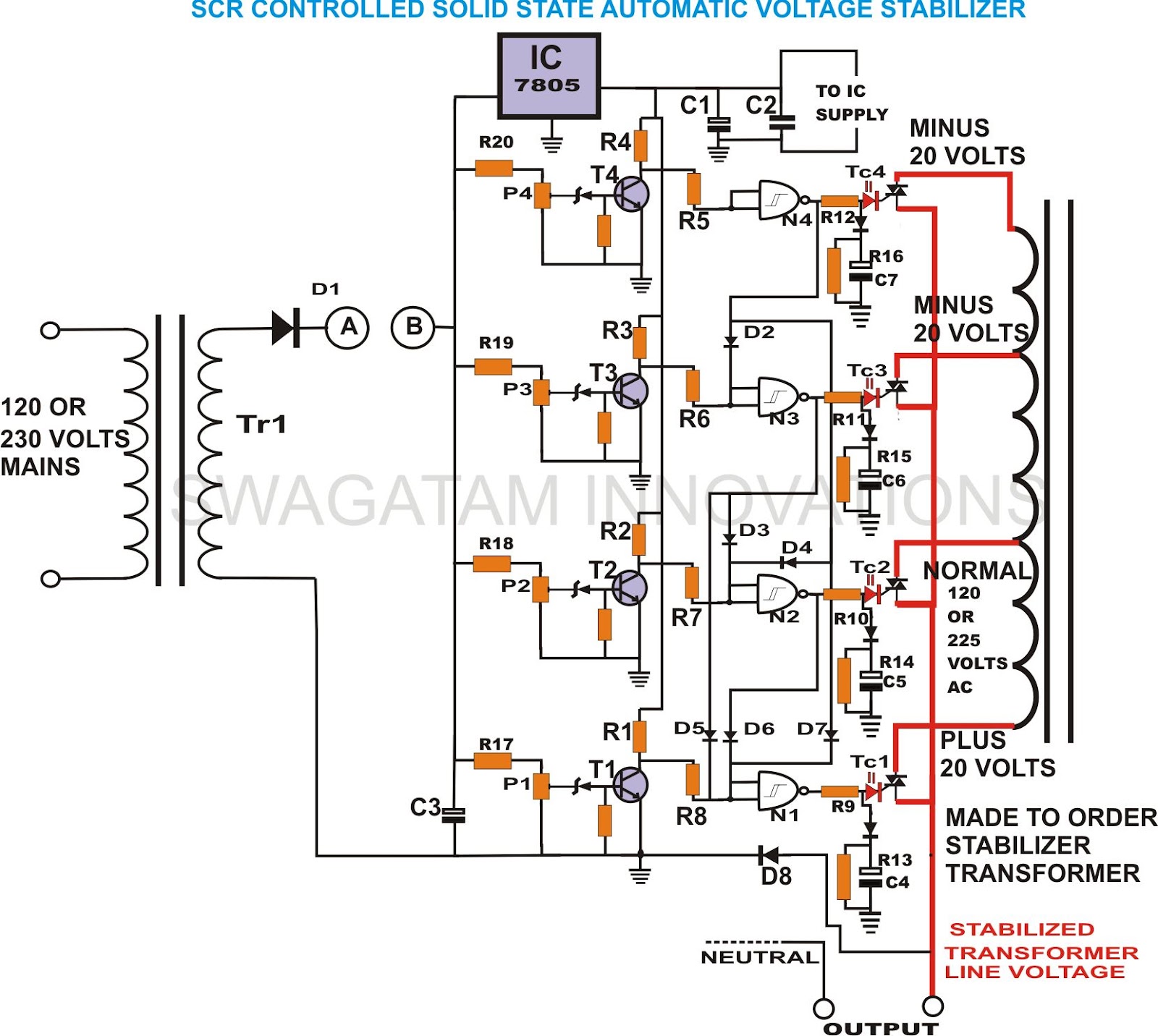

This unique and hard-to-find triac-controlled AC voltage stabilizer circuit has been specifically designed for efficient voltage stabilization. With a solid-state design, the voltage switching transitions are smooth, resulting in minimal wear and tear. The proposed circuit provides four-step voltage stabilization for any appliance at its output. The absence of moving parts enhances its efficiency. Unlike simpler automatic voltage stabilizers, this design allows for discrete control of varying mains voltages. Although the circuit has not been tested, it appears promising, and proper dimensioning of critical components should yield expected results. This triac-controlled AC voltage stabilizer excels in performance and is nearly ideal for voltage stabilization. The circuit is designed to accurately control and dimension the input AC mains voltage through four independent steps. Triacs ensure quick changeovers (within 2 ms) without sparks or transients associated with relay-type stabilizers. The entire unit is solid-state and nearly permanent. Caution is advised, as all points in the circuit may be at AC mains potential, making it extremely dangerous to touch when switched on. It is recommended to use a wooden plank underfoot and for beginners to avoid this project. Transistors T1 to T4 are arranged to sense gradual rises in input voltage, conducting sequentially as the voltage increases or decreases. As the input voltage rises, the gates respond to the transistors, ensuring that only the current gate is active while the previous gate is turned off. The logic high output from the buffer is applied to the gate of the respective SCR, which conducts and connects the relevant hot line from the transformer to the external appliance. This design allows the triacs to select the appropriate hot ends of the transformer to maintain a stabilized output. The construction of this triac-controlled AC power guard circuit is straightforward, requiring the proper parts and assembly on a general PCB. A basic understanding of electronics is necessary, as errors in assembly can lead to significant issues. Based on calculations, an output supply of 12 volts from TR1 corresponds to a 225-volt input supply, resulting in 9 volts at 170 volts input, 13 volts at 245 volts, and 14 volts at approximately 260 volts input. Performance can be verified by supplying varying AC input through an auto transformer and measuring the output with a digital multimeter.

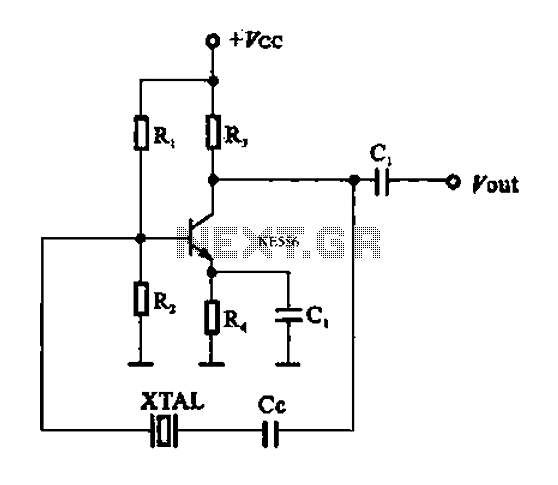

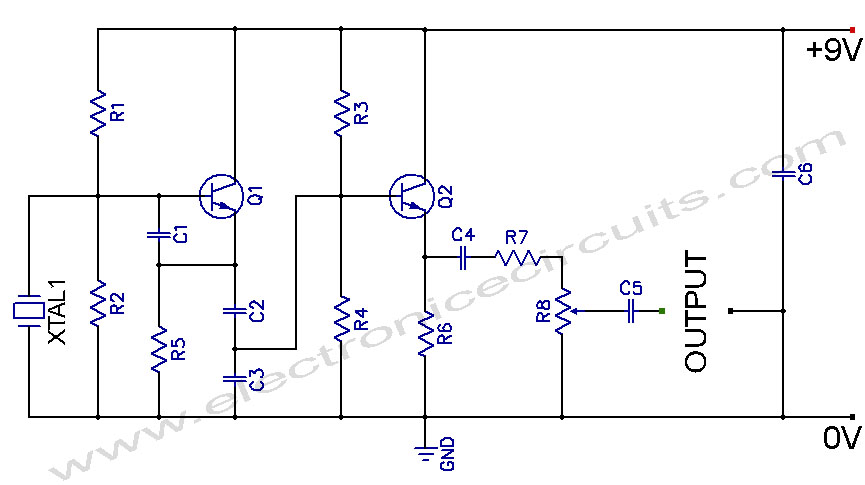

The triac-controlled AC voltage stabilizer circuit operates by continuously monitoring the input voltage and adjusting the output accordingly through a series of triacs and transistors. The circuit employs a feedback mechanism where transistors T1 to T4 are configured to detect voltage levels and activate the corresponding triac based on the voltage range. Each triac is responsible for connecting the output to a specific tap on the transformer, allowing for precise voltage control.

The design incorporates a transformer with multiple taps, which provides different voltage levels. As the input AC voltage fluctuates, the circuit dynamically selects the appropriate tap to maintain a stable output voltage. This is achieved by the rapid switching capabilities of the triacs, which can respond within milliseconds, ensuring that the output remains stable even with significant variations in input voltage.

The circuit is built around a general-purpose PCB, making it accessible for those with intermediate electronics skills. Key components include the triacs, transistors, resistors, capacitors, and the transformer. Proper selection and sizing of these components are critical to ensure reliable operation and safety. It is essential to follow the schematic closely during assembly to prevent misconfigurations that could lead to circuit failure or hazards.

Given the nature of the circuit, it is imperative to implement safety precautions. The circuit operates at mains voltage, which poses a risk of electric shock. Therefore, adequate insulation and protective measures should be in place during both assembly and operation. It is advisable to test the circuit in a controlled environment and to use equipment such as an auto transformer and a digital multimeter for performance verification, allowing for adjustments and ensuring the output voltage remains within desired parameters.This one of its kind and hard to find triac control AC voltage stabilizer circuit has been designed specifically just for you. Being solid state in design, the voltage switching transitions are very smooth with minimum wear and tear, resulting in efficient voltage stabilization.

Discover the whole construction procedure of this unique, solid state mains voltage stabilizer. The proposed circuit of a triac controlled AC voltage stabilizer will provide an excellent 4 step voltage stabilization to any appliance at its output. With no moving parts involved its efficiency is further enhanced. Find out more of this silent operator: power guard. The circuit of an automatic voltage stabilizer discussed in one of my previous articles, though useful, due to its simpler design, does not have the capability of controlling the different levels of varying mains voltages discretely.

The proposed idea though not tested, looks pretty convincing, and if the critical components are properly dimensioned, should work as expected. The present circuit of triac controlled AC voltage stabilizer is outstanding in its performance and is almost an ideal voltage stabilizer in every respect.

As usual the circuit has been exclusively designed by me. It is able to control and dimension the input AC mains voltage accurately through 4 independent steps. The use of triacs make it sure that the changeovers are quick (within 2 mS) and with no sparks or transients usually associated with relay type of stabilizers.

Also since no moving parts are employed, the entire unit becomes completely solid state and almost permanent. CAUTION: EACH AND EVERY POINT OF THE CIRCUIT PRESENTED HERE MAY BE AT AC MAINS POTENTIAL, THEREFORE EXTEMELY DANGEROUS TO TOUCH IN SWITCHED ON POSITION.

UTMOST CARE AND CAUTION IS ADVISED, USE OF A WOODEN PLANCK UNDER YOUR FEET IS RECOMMENDED. NEWBIES PLEASE KEEP AWAY. Transistors T1 to T4 are all arranged to sense the gradual rise in the input voltage and conduct one after the other in sequence as the voltage rises and vice versa. Thus, as the input voltage rises the gates respond to the transistors and their outputs subsequently become logic hi one after the other making sure that the previous gate`s output is shut OFF and vice versa.

The logic hi from the particular buffer is applied to the gate of the respective SCR which conducts and connects the relevant hot line from the transformer to the external connected appliance. As the voltage rises, the relevant triacs subsequently select the appropriate hot ends of the transformer to increase or decrease the voltage and maintain a relatively stabilized output.

The construction of this triac control AC power guard circuit is simple and just a matter of procuring the required parts and assembling them correctly over a general PCB. It is pretty obvious that the person who is attempting to make this circuit knows a bit more than just the basics of electronics.

Things may go drastically wrong if there is any error in the final assembly. Assuming that an output supply of 12 volts from TR1 corresponds to 225 volts input supply, through calculations we find that it will produce 9 volts at an input of 170 volts, 13 volts will correspond to 245 volts and 14 volts will be equivalent to an input of approximately 260 volts. You may verify the performance of the system by supplying a varying input AC through an auto transformer and checking the output using a digital multimeter.

🔗 External reference

The triac-controlled AC voltage stabilizer circuit operates by continuously monitoring the input voltage and adjusting the output accordingly through a series of triacs and transistors. The circuit employs a feedback mechanism where transistors T1 to T4 are configured to detect voltage levels and activate the corresponding triac based on the voltage range. Each triac is responsible for connecting the output to a specific tap on the transformer, allowing for precise voltage control.

The design incorporates a transformer with multiple taps, which provides different voltage levels. As the input AC voltage fluctuates, the circuit dynamically selects the appropriate tap to maintain a stable output voltage. This is achieved by the rapid switching capabilities of the triacs, which can respond within milliseconds, ensuring that the output remains stable even with significant variations in input voltage.

The circuit is built around a general-purpose PCB, making it accessible for those with intermediate electronics skills. Key components include the triacs, transistors, resistors, capacitors, and the transformer. Proper selection and sizing of these components are critical to ensure reliable operation and safety. It is essential to follow the schematic closely during assembly to prevent misconfigurations that could lead to circuit failure or hazards.

Given the nature of the circuit, it is imperative to implement safety precautions. The circuit operates at mains voltage, which poses a risk of electric shock. Therefore, adequate insulation and protective measures should be in place during both assembly and operation. It is advisable to test the circuit in a controlled environment and to use equipment such as an auto transformer and a digital multimeter for performance verification, allowing for adjustments and ensuring the output voltage remains within desired parameters.This one of its kind and hard to find triac control AC voltage stabilizer circuit has been designed specifically just for you. Being solid state in design, the voltage switching transitions are very smooth with minimum wear and tear, resulting in efficient voltage stabilization.

Discover the whole construction procedure of this unique, solid state mains voltage stabilizer. The proposed circuit of a triac controlled AC voltage stabilizer will provide an excellent 4 step voltage stabilization to any appliance at its output. With no moving parts involved its efficiency is further enhanced. Find out more of this silent operator: power guard. The circuit of an automatic voltage stabilizer discussed in one of my previous articles, though useful, due to its simpler design, does not have the capability of controlling the different levels of varying mains voltages discretely.

The proposed idea though not tested, looks pretty convincing, and if the critical components are properly dimensioned, should work as expected. The present circuit of triac controlled AC voltage stabilizer is outstanding in its performance and is almost an ideal voltage stabilizer in every respect.

As usual the circuit has been exclusively designed by me. It is able to control and dimension the input AC mains voltage accurately through 4 independent steps. The use of triacs make it sure that the changeovers are quick (within 2 mS) and with no sparks or transients usually associated with relay type of stabilizers.

Also since no moving parts are employed, the entire unit becomes completely solid state and almost permanent. CAUTION: EACH AND EVERY POINT OF THE CIRCUIT PRESENTED HERE MAY BE AT AC MAINS POTENTIAL, THEREFORE EXTEMELY DANGEROUS TO TOUCH IN SWITCHED ON POSITION.

UTMOST CARE AND CAUTION IS ADVISED, USE OF A WOODEN PLANCK UNDER YOUR FEET IS RECOMMENDED. NEWBIES PLEASE KEEP AWAY. Transistors T1 to T4 are all arranged to sense the gradual rise in the input voltage and conduct one after the other in sequence as the voltage rises and vice versa. Thus, as the input voltage rises the gates respond to the transistors and their outputs subsequently become logic hi one after the other making sure that the previous gate`s output is shut OFF and vice versa.

The logic hi from the particular buffer is applied to the gate of the respective SCR which conducts and connects the relevant hot line from the transformer to the external connected appliance. As the voltage rises, the relevant triacs subsequently select the appropriate hot ends of the transformer to increase or decrease the voltage and maintain a relatively stabilized output.

The construction of this triac control AC power guard circuit is simple and just a matter of procuring the required parts and assembling them correctly over a general PCB. It is pretty obvious that the person who is attempting to make this circuit knows a bit more than just the basics of electronics.

Things may go drastically wrong if there is any error in the final assembly. Assuming that an output supply of 12 volts from TR1 corresponds to 225 volts input supply, through calculations we find that it will produce 9 volts at an input of 170 volts, 13 volts will correspond to 245 volts and 14 volts will be equivalent to an input of approximately 260 volts. You may verify the performance of the system by supplying a varying input AC through an auto transformer and checking the output using a digital multimeter.

🔗 External reference