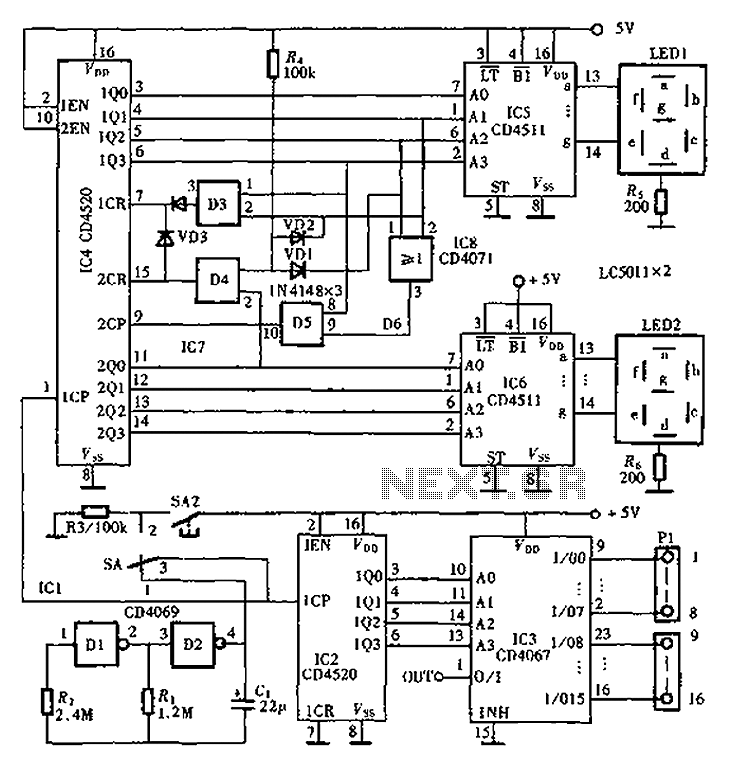

CD4520 CD4511 CD4067 digital automatic inspection circuit diagram

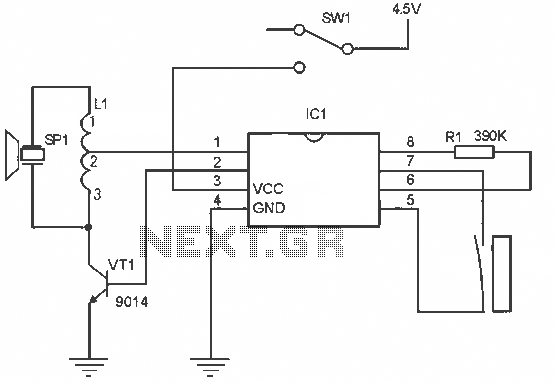

An automatic inspection circuit designed for the simultaneous detection and control of multiple production equipment. This inspection circuit can perform sixteen regular inspections of production equipment. It consists of a pulse generator, multiple inspection circuits, and an automatic inspection channel with a digital display circuit.

The automatic inspection circuit integrates several key components to facilitate the efficient monitoring and control of production equipment. At the core of the system is a pulse generator, which generates a series of electrical pulses that trigger the inspection process. This pulse generator is crucial for synchronizing the operation of the inspection circuits, ensuring that each piece of equipment is inspected in a timely and orderly manner.

The circuit includes sixteen individual inspection channels, each dedicated to monitoring a specific piece of production equipment. These channels are equipped with various sensors and detection mechanisms that assess the operational status and performance metrics of the equipment. The data collected by these sensors is processed in real-time, enabling immediate detection of any anomalies or malfunctions.

Additionally, the output from each inspection channel is routed to an automatic inspection channel that consolidates the information for display and analysis. This channel is equipped with a digital display circuit that presents the inspection results in a clear and accessible format. Operators can easily view the status of each piece of equipment, allowing for prompt decision-making and intervention when necessary.

Overall, this automatic inspection circuit enhances the reliability and efficiency of production processes by providing comprehensive monitoring and control capabilities. It is an essential component in modern manufacturing systems, where precision and timely maintenance are critical for optimal performance. Automatic inspection circuit for multiple detection and control of production equipment, the inspection circuit may sixteen regular inspection of production equipment. It consi sts of a pulse generator inspection, Sixteenth Street circuits and automatic inspection channel digital display circuit, as shown in FIG.

The automatic inspection circuit integrates several key components to facilitate the efficient monitoring and control of production equipment. At the core of the system is a pulse generator, which generates a series of electrical pulses that trigger the inspection process. This pulse generator is crucial for synchronizing the operation of the inspection circuits, ensuring that each piece of equipment is inspected in a timely and orderly manner.

The circuit includes sixteen individual inspection channels, each dedicated to monitoring a specific piece of production equipment. These channels are equipped with various sensors and detection mechanisms that assess the operational status and performance metrics of the equipment. The data collected by these sensors is processed in real-time, enabling immediate detection of any anomalies or malfunctions.

Additionally, the output from each inspection channel is routed to an automatic inspection channel that consolidates the information for display and analysis. This channel is equipped with a digital display circuit that presents the inspection results in a clear and accessible format. Operators can easily view the status of each piece of equipment, allowing for prompt decision-making and intervention when necessary.

Overall, this automatic inspection circuit enhances the reliability and efficiency of production processes by providing comprehensive monitoring and control capabilities. It is an essential component in modern manufacturing systems, where precision and timely maintenance are critical for optimal performance. Automatic inspection circuit for multiple detection and control of production equipment, the inspection circuit may sixteen regular inspection of production equipment. It consi sts of a pulse generator inspection, Sixteenth Street circuits and automatic inspection channel digital display circuit, as shown in FIG.