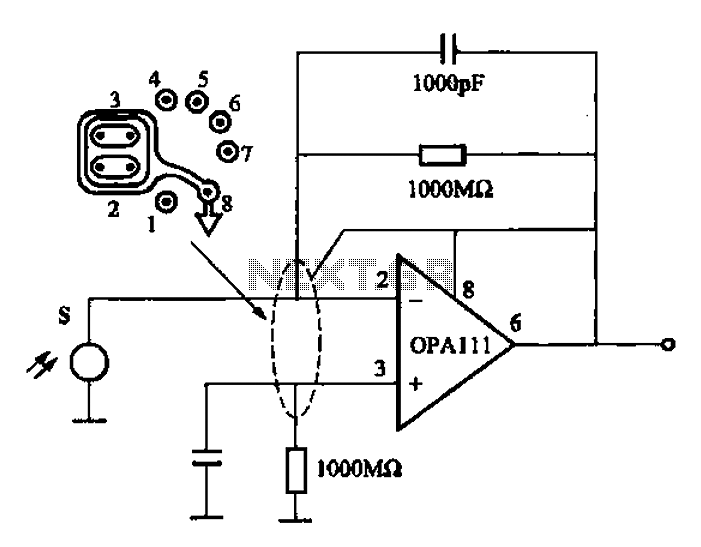

Coke Thermal infrared detection circuit OPA111

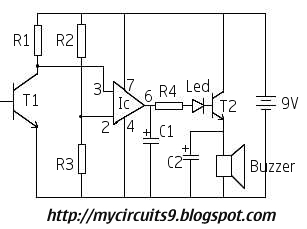

Infrared heat is emitted by an object during non-contact temperature measurement. The measured signal is weak, necessitating the use of highly sensitive thermal infrared sensors with minimal noise. Consequently, the amplifier circuit must also meet stringent requirements, as standard operational amplifiers do not suffice. The OPA111 is integrated into the infrared thermal measurement circuit. The general circuit structure resembles that of an operational amplifier, but it features a significantly large feedback resistor to achieve a high gain. The signal pin and copper traces on the printed circuit board require careful masking. Due to the high gain of the amplifier, inadequate shielding may lead to interference from external noise.

The application of infrared heat emission in non-contact temperature measurement involves the detection of thermal radiation from an object. This process is critical in various fields, including industrial monitoring, medical diagnostics, and environmental assessments. The primary challenge in this measurement technique lies in the weak nature of the infrared signal emitted by the object, which necessitates the use of highly sensitive thermal infrared sensors. These sensors must exhibit a high degree of sensitivity and low noise characteristics to ensure accurate temperature readings.

The OPA111 operational amplifier is specifically designed to address the challenges associated with amplifying weak infrared signals. Its architecture allows for a high gain, which is essential for enhancing the minute signals detected by the sensor. The circuit design incorporates a large feedback resistor, which is crucial for achieving the required gain without compromising the stability of the amplifier. This configuration ensures that the amplifier can effectively process the weak signals while minimizing distortion.

In addition to the amplifier design, careful attention must be paid to the layout of the printed circuit board (PCB). The signal pin and copper traces must be meticulously processed to minimize parasitic capacitance and inductance, which could adversely affect the signal integrity. Shielding is also a vital consideration in the design process. Given the high gain of the OPA111, any external electromagnetic interference could significantly impact the performance of the measurement system. Therefore, appropriate shielding techniques must be employed to protect the circuit from noise, ensuring reliable and accurate temperature measurements.

Overall, the integration of the OPA111 into the infrared thermal measurement circuit exemplifies the importance of selecting the right components and implementing thoughtful design practices to achieve high-performance non-contact temperature measurement systems.An application focus infrared heat is radiated by an object while the object of infrared non-contact temperature measurement, since the detection of the measured signal is very weak, thus requiring the use of coke thermal infrared sensor sensitivity must be very high, the noise is very small; the same of the amplifier circuit is also very demanding, with the general operational amplifier is unable to meet the requirements. OPA111 structure into focus infrared thermal measurement circuit as shown in FIG. The general structure of the circuit as an operational amplifier, except that the feedback resistor is very large (requires gain is very large); signal pin signal lead and copper traces printed circuit board must make the mask processing.

Because the gain of the amplifier is large, if not shielded, then external noise can cause interference.

The application of infrared heat emission in non-contact temperature measurement involves the detection of thermal radiation from an object. This process is critical in various fields, including industrial monitoring, medical diagnostics, and environmental assessments. The primary challenge in this measurement technique lies in the weak nature of the infrared signal emitted by the object, which necessitates the use of highly sensitive thermal infrared sensors. These sensors must exhibit a high degree of sensitivity and low noise characteristics to ensure accurate temperature readings.

The OPA111 operational amplifier is specifically designed to address the challenges associated with amplifying weak infrared signals. Its architecture allows for a high gain, which is essential for enhancing the minute signals detected by the sensor. The circuit design incorporates a large feedback resistor, which is crucial for achieving the required gain without compromising the stability of the amplifier. This configuration ensures that the amplifier can effectively process the weak signals while minimizing distortion.

In addition to the amplifier design, careful attention must be paid to the layout of the printed circuit board (PCB). The signal pin and copper traces must be meticulously processed to minimize parasitic capacitance and inductance, which could adversely affect the signal integrity. Shielding is also a vital consideration in the design process. Given the high gain of the OPA111, any external electromagnetic interference could significantly impact the performance of the measurement system. Therefore, appropriate shielding techniques must be employed to protect the circuit from noise, ensuring reliable and accurate temperature measurements.

Overall, the integration of the OPA111 into the infrared thermal measurement circuit exemplifies the importance of selecting the right components and implementing thoughtful design practices to achieve high-performance non-contact temperature measurement systems.An application focus infrared heat is radiated by an object while the object of infrared non-contact temperature measurement, since the detection of the measured signal is very weak, thus requiring the use of coke thermal infrared sensor sensitivity must be very high, the noise is very small; the same of the amplifier circuit is also very demanding, with the general operational amplifier is unable to meet the requirements. OPA111 structure into focus infrared thermal measurement circuit as shown in FIG. The general structure of the circuit as an operational amplifier, except that the feedback resistor is very large (requires gain is very large); signal pin signal lead and copper traces printed circuit board must make the mask processing.

Because the gain of the amplifier is large, if not shielded, then external noise can cause interference.