Data Transfer interface

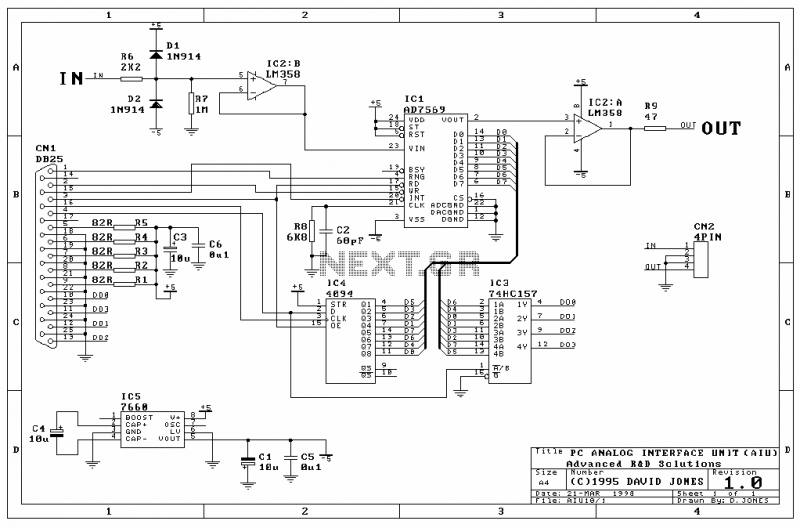

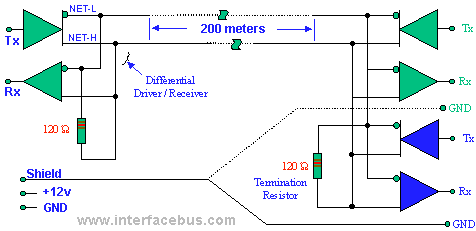

The DS protocol was designed to provide firmware-based bidirectional host-to-slave inter-processor communications for situations in which no hardware solution is available and the host and/or the slave is incapable of tending the interface in real-time. The only specialized hardware required is two bidirectional I/O ports on each chip (alternatively, two input ports and two tri-statable output ports may be used). In other words, it provides some of the functionality of the Two-Wire Interface (TWI, or I2C as named by Philips) where an actual TWI is not feasible in either hardware or firmware. The 5 volt power pin on the DS interface may be used to supply power to the DS device being tested. In this case, a power on-off switch would be a good idea. The microcontroller timing is unimportant for the DS device, but it is critical for the baud rate generator on the AT902313. The RS-232 inverters could also be Maxim MAX-232 or something similar. Discreet inverters are preferred as they take less board space than the DIP buffers when building by hand.

On the DS interface side, the firmware provides for weak internal pull-ups on the Attention and Data lines, so no external resistors are required unless there is a large capacitive load on these lines, in which case resistors as low as 270 Ohms may be used.

The DS protocol enables effective communication between a host microcontroller and slave devices in scenarios where dedicated hardware interfaces are not available. The two I/O ports required for this protocol can be configured flexibly, allowing for various implementation strategies depending on the available resources of the microcontroller. The firmware-driven nature of this protocol facilitates adaptability in terms of communication timing and data handling, enabling operations even in low-power or resource-constrained environments.

In practical applications, the 5V power pin serves a dual purpose: it not only powers the DS device under test but also simplifies the circuit design by reducing the need for additional power supply components. Implementing a power switch enhances usability by allowing power control during testing or development phases.

The requirement for precise timing is emphasized in the context of the AT902313's baud rate generator, highlighting the importance of synchronization in serial communications. The use of RS-232 inverters, such as the Maxim MAX-232, is a common practice in interfacing with standard serial communication protocols. These inverters are compact and allow for efficient signal level conversions, making them suitable for hand-built circuits.

The firmware's provision of weak internal pull-ups on the Attention and Data lines is a significant feature that reduces the component count in the design. However, in scenarios where external capacitance may affect signal integrity, the inclusion of external resistors becomes necessary to maintain reliable communication. The suggested value of 270 Ohms serves as a guideline to mitigate potential issues arising from capacitive loading, ensuring that the signals remain within acceptable voltage levels for proper device operation. This design consideration is crucial for maintaining the robustness of the DS communication protocol in diverse applications.The DS protocol was designed to provide firmware-based bidirectional host-to-slave inter processor communications for situations in which no hardware solution is available and the host and/or the slave in incapable of tending the interface in real time. The only specialized hardware required is two bidirectional I/O ports on each chip (alternatively two input ports and two tri-statable output ports may be used.

In other words, it provides some of the functionalit of the Two-Wire-Interface (TWI, or I2C as named by Philips) where an actual TWI is not feasible in either hardware or firmware. The 5 volt power pin on the DS interface may be used to supply power to the DS device being tested. In this case, a power on-off switch would be a good idea. The microcontroller timing is unimportant for the DS device, but it is critical for the baud rate generator on the AT902313. The RS-232 inverters could also be Maxim MAX-232 or something similar. I prefer these discreet inverters because I am building them by hand and they take less board space than the DIP buffers.

On the DS interface side, the firmware provides for week internal pullups on the Attention and Data lines, so no nexternal resistors are required unless there is a large capactive load on these lines, in which casce, resistors as low as 270 Ohms may be used. 🔗 External reference

On the DS interface side, the firmware provides for weak internal pull-ups on the Attention and Data lines, so no external resistors are required unless there is a large capacitive load on these lines, in which case resistors as low as 270 Ohms may be used.

The DS protocol enables effective communication between a host microcontroller and slave devices in scenarios where dedicated hardware interfaces are not available. The two I/O ports required for this protocol can be configured flexibly, allowing for various implementation strategies depending on the available resources of the microcontroller. The firmware-driven nature of this protocol facilitates adaptability in terms of communication timing and data handling, enabling operations even in low-power or resource-constrained environments.

In practical applications, the 5V power pin serves a dual purpose: it not only powers the DS device under test but also simplifies the circuit design by reducing the need for additional power supply components. Implementing a power switch enhances usability by allowing power control during testing or development phases.

The requirement for precise timing is emphasized in the context of the AT902313's baud rate generator, highlighting the importance of synchronization in serial communications. The use of RS-232 inverters, such as the Maxim MAX-232, is a common practice in interfacing with standard serial communication protocols. These inverters are compact and allow for efficient signal level conversions, making them suitable for hand-built circuits.

The firmware's provision of weak internal pull-ups on the Attention and Data lines is a significant feature that reduces the component count in the design. However, in scenarios where external capacitance may affect signal integrity, the inclusion of external resistors becomes necessary to maintain reliable communication. The suggested value of 270 Ohms serves as a guideline to mitigate potential issues arising from capacitive loading, ensuring that the signals remain within acceptable voltage levels for proper device operation. This design consideration is crucial for maintaining the robustness of the DS communication protocol in diverse applications.The DS protocol was designed to provide firmware-based bidirectional host-to-slave inter processor communications for situations in which no hardware solution is available and the host and/or the slave in incapable of tending the interface in real time. The only specialized hardware required is two bidirectional I/O ports on each chip (alternatively two input ports and two tri-statable output ports may be used.

In other words, it provides some of the functionalit of the Two-Wire-Interface (TWI, or I2C as named by Philips) where an actual TWI is not feasible in either hardware or firmware. The 5 volt power pin on the DS interface may be used to supply power to the DS device being tested. In this case, a power on-off switch would be a good idea. The microcontroller timing is unimportant for the DS device, but it is critical for the baud rate generator on the AT902313. The RS-232 inverters could also be Maxim MAX-232 or something similar. I prefer these discreet inverters because I am building them by hand and they take less board space than the DIP buffers.

On the DS interface side, the firmware provides for week internal pullups on the Attention and Data lines, so no nexternal resistors are required unless there is a large capactive load on these lines, in which casce, resistors as low as 270 Ohms may be used. 🔗 External reference