Electric sewing machine saving circuit

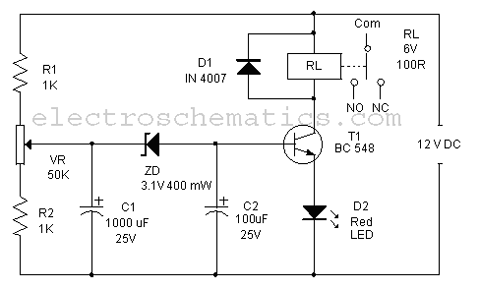

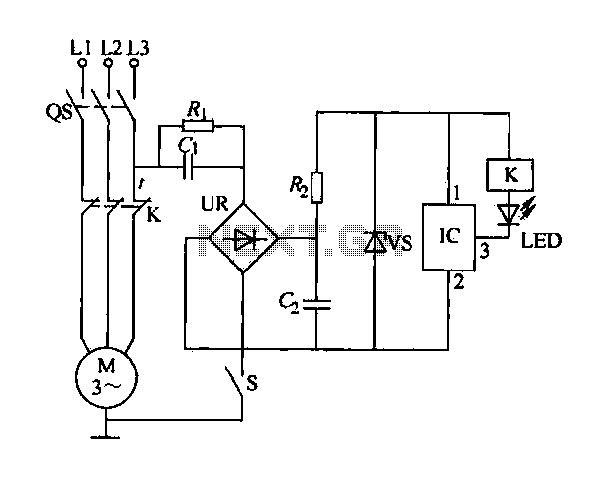

The electric sewing machine saving circuit is designed with a Hall switch integrated circuit (IC) and a relay (K). When the switch is closed, power is activated. The circuit includes a resistor (R) and a capacitor (Ci) for RC buck conversion. The silicon rectifier bridge (UR) is utilized for rectification, followed by a filter (G) and a voltage regulator IC that provides a 12V DC power supply. When the operator does not engage the sewing machine foot pedal, the magnet remains in the operating position corresponding to the IC. The relay (K) is energized, opening the normally closed contact, which prevents power to the sewing machine, causing a red light-emitting diode (LED) to illuminate. Conversely, when the foot pedal is pressed, the fixed magnetic clutch lever (FI1) on the machine engages, disrupting the magnetic field sensed by the IC. This results in a high potential at the relay (K), which releases power, resetting the normally closed contacts, allowing the main circuit to operate and turning off the LED.

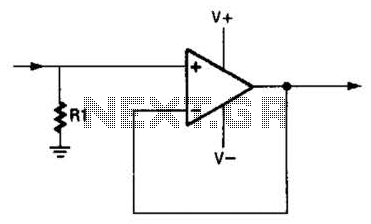

The electric sewing machine saving circuit operates through a combination of a Hall effect sensor and a relay mechanism to enhance energy efficiency and user safety. The Hall switch IC detects the presence of a magnetic field generated by the foot pedal's magnet. When the circuit is powered, the resistor (R) and capacitor (Ci) form an RC network that ensures stable operation of the relay and prevents voltage spikes.

The silicon rectifier bridge (UR) converts the alternating current (AC) from the power source into direct current (DC), which is then smoothed by the filter (G). The voltage regulator IC ensures that the output voltage remains stable at 12V DC, which is essential for the proper functioning of the sewing machine's electronic components.

In the idle state, when the operator is not pressing the foot pedal, the Hall switch IC detects the magnetic field, causing the relay (K) to remain energized. This action opens the normally closed contact, effectively cutting off power to the sewing machine and illuminating the red LED as an indicator that the machine is not operational.

When the operator engages the foot pedal, the magnetic clutch lever (FI1) is activated, disrupting the magnetic field detected by the Hall switch IC. This loss of magnetic field causes the relay (K) to de-energize, closing the normally closed contact, which allows current to flow to the sewing machine. The LED indicator turns off, signaling that the machine is now powered and ready for operation.

This circuit design is particularly beneficial in preventing accidental activation of the sewing machine when it is not in use, thereby enhancing safety and reducing energy consumption. The integration of the Hall effect sensor with the relay mechanism allows for a responsive and reliable control system, ensuring that the sewing machine operates only when intended.Electric sewing machine saving circuit as shown, line the main elements by the Hall switch IC IC and relay K composition. Closing switch os, power-on, after R, and Ci RC Buck, UR rectifier bridge silicon, G filter, vs the regulator, IC to provide the 12V DC power supply e when the operator does not move the sewing machine foot pedal magnet in the operating position corresponding to the IC. K pull power, open the normally closed contact, seam sewing machine is not powered. Red light-emitting diode (LED) lights. On the other hand, stepped on a sewing machine, FI1 attached to the fixed magnetic clutch lever on the machine l of iron down.

IC lose magnetic field, which was feet high potential, K loss of power release, the main circuit normally closed contacts reset, M running, LED is off.

The electric sewing machine saving circuit operates through a combination of a Hall effect sensor and a relay mechanism to enhance energy efficiency and user safety. The Hall switch IC detects the presence of a magnetic field generated by the foot pedal's magnet. When the circuit is powered, the resistor (R) and capacitor (Ci) form an RC network that ensures stable operation of the relay and prevents voltage spikes.

The silicon rectifier bridge (UR) converts the alternating current (AC) from the power source into direct current (DC), which is then smoothed by the filter (G). The voltage regulator IC ensures that the output voltage remains stable at 12V DC, which is essential for the proper functioning of the sewing machine's electronic components.

In the idle state, when the operator is not pressing the foot pedal, the Hall switch IC detects the magnetic field, causing the relay (K) to remain energized. This action opens the normally closed contact, effectively cutting off power to the sewing machine and illuminating the red LED as an indicator that the machine is not operational.

When the operator engages the foot pedal, the magnetic clutch lever (FI1) is activated, disrupting the magnetic field detected by the Hall switch IC. This loss of magnetic field causes the relay (K) to de-energize, closing the normally closed contact, which allows current to flow to the sewing machine. The LED indicator turns off, signaling that the machine is now powered and ready for operation.

This circuit design is particularly beneficial in preventing accidental activation of the sewing machine when it is not in use, thereby enhancing safety and reducing energy consumption. The integration of the Hall effect sensor with the relay mechanism allows for a responsive and reliable control system, ensuring that the sewing machine operates only when intended.Electric sewing machine saving circuit as shown, line the main elements by the Hall switch IC IC and relay K composition. Closing switch os, power-on, after R, and Ci RC Buck, UR rectifier bridge silicon, G filter, vs the regulator, IC to provide the 12V DC power supply e when the operator does not move the sewing machine foot pedal magnet in the operating position corresponding to the IC. K pull power, open the normally closed contact, seam sewing machine is not powered. Red light-emitting diode (LED) lights. On the other hand, stepped on a sewing machine, FI1 attached to the fixed magnetic clutch lever on the machine l of iron down.

IC lose magnetic field, which was feet high potential, K loss of power release, the main circuit normally closed contacts reset, M running, LED is off.