fez accutest circuit

This page describes a battery tester designed to characterize batteries and save the results on a microSD card.

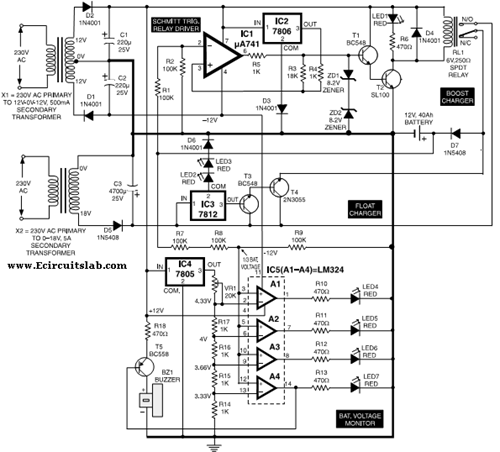

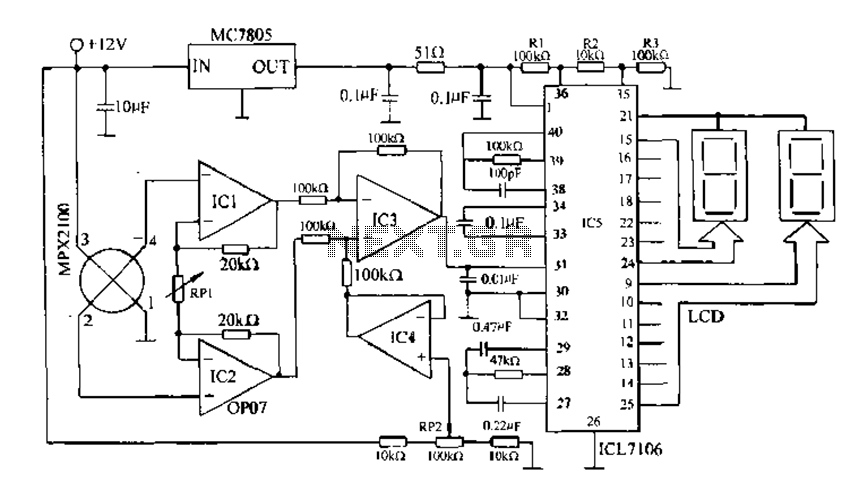

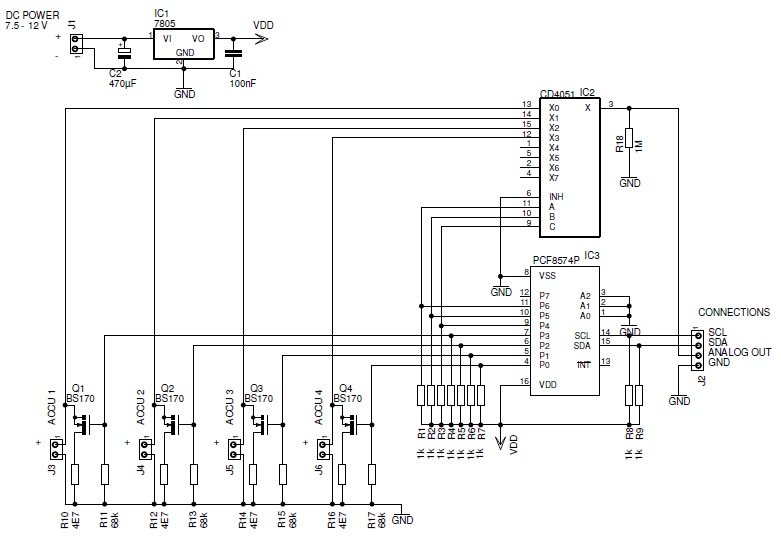

The battery tester circuit is engineered to evaluate the performance and capacity of various battery types, providing accurate and reliable data storage via a microSD card. The core components of the circuit include a microcontroller, an analog-to-digital converter (ADC), a voltage divider, and a microSD card module.

The microcontroller serves as the central processing unit, controlling the operation of the tester and managing data acquisition. It is programmed to initiate the testing sequence, read voltage levels from the battery under test, and process the data for characterization. The ADC is utilized to convert the analog voltage readings from the battery into digital values that the microcontroller can interpret.

A voltage divider circuit is employed to scale the battery voltage to a level within the acceptable range for the ADC. This ensures that the microcontroller receives accurate voltage readings, which are critical for determining the battery's state of charge and overall health.

The microSD card module is interfaced with the microcontroller to facilitate data storage. Once the battery testing is complete, the results, including voltage levels and any other relevant metrics, are written to the microSD card in a structured format. This allows for easy retrieval and analysis of the battery performance data.

Power supply considerations for the circuit include the use of a regulated power source to ensure stable operation of the microcontroller and other components. Additionally, proper filtering and decoupling capacitors should be implemented to minimize noise and enhance the reliability of the measurements.

Overall, this battery tester circuit is designed to provide a comprehensive solution for battery characterization, with an emphasis on accurate data collection and ease of use through the integration of a microSD card for data storage.This page describes a battery tester I designed. It will characterize your batteries and save the results on an microSD card.. 🔗 External reference

The battery tester circuit is engineered to evaluate the performance and capacity of various battery types, providing accurate and reliable data storage via a microSD card. The core components of the circuit include a microcontroller, an analog-to-digital converter (ADC), a voltage divider, and a microSD card module.

The microcontroller serves as the central processing unit, controlling the operation of the tester and managing data acquisition. It is programmed to initiate the testing sequence, read voltage levels from the battery under test, and process the data for characterization. The ADC is utilized to convert the analog voltage readings from the battery into digital values that the microcontroller can interpret.

A voltage divider circuit is employed to scale the battery voltage to a level within the acceptable range for the ADC. This ensures that the microcontroller receives accurate voltage readings, which are critical for determining the battery's state of charge and overall health.

The microSD card module is interfaced with the microcontroller to facilitate data storage. Once the battery testing is complete, the results, including voltage levels and any other relevant metrics, are written to the microSD card in a structured format. This allows for easy retrieval and analysis of the battery performance data.

Power supply considerations for the circuit include the use of a regulated power source to ensure stable operation of the microcontroller and other components. Additionally, proper filtering and decoupling capacitors should be implemented to minimize noise and enhance the reliability of the measurements.

Overall, this battery tester circuit is designed to provide a comprehensive solution for battery characterization, with an emphasis on accurate data collection and ease of use through the integration of a microSD card for data storage.This page describes a battery tester I designed. It will characterize your batteries and save the results on an microSD card.. 🔗 External reference