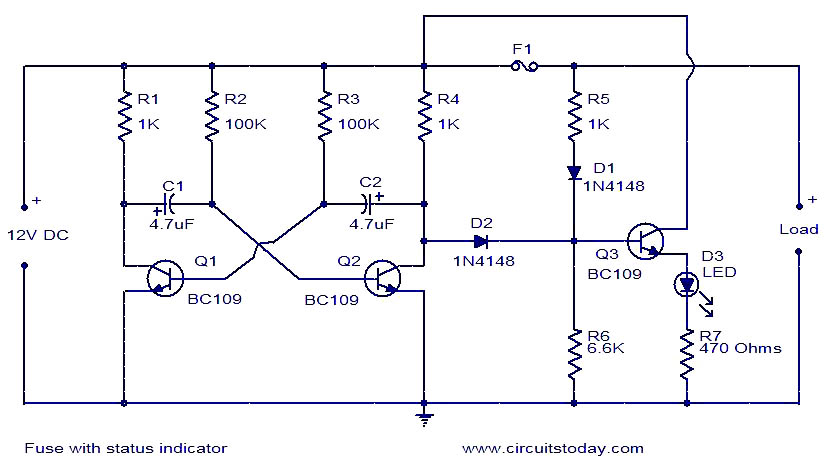

Fuse with status indicator

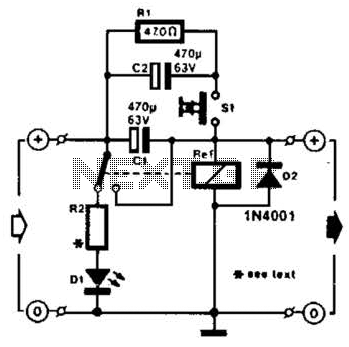

The circuit diagram presented illustrates a fuse with an automatic status indicator, designed for operation with a 12V DC supply. While the fuse remains intact, the LED D3 emits a continuous glow; however, if the fuse blows, the LED will begin to blink. The circuit's initial section features an astable multivibrator constructed with transistors Q1 and Q2. The output from this multivibrator is connected to the base of transistor Q3 through diode D2. When the fuse is intact, resistor R5 pulls the base of Q3 to a positive voltage, keeping the transistor in an ON state and allowing LED D3 to remain illuminated. If the fuse blows, the base of Q3 loses the positive voltage, and the only biasing available comes from the astable multivibrator's output. Consequently, transistor Q3 begins to switch at the frequency determined by the astable multivibrator, causing the LED to blink in response.

The circuit operates on a 12V DC supply, making it suitable for various automotive and electronic applications. The astable multivibrator, formed by transistors Q1 and Q2, generates a square wave output that toggles between high and low states. This oscillation is crucial for the blinking function of the LED, providing a visual indication of the fuse status.

In the circuit, when the fuse is functional, the continuous current flow through the LED D3 is maintained, indicating normal operation. The inclusion of diode D2 ensures that the output from the astable multivibrator does not interfere with the biasing of Q3 when the fuse is intact. Resistor R5 plays a vital role in establishing the base current for Q3, ensuring it remains in the conductive state.

Upon fuse failure, the absence of a positive voltage at the base of Q3 leads to a change in its operating state. The astable multivibrator's output now becomes the primary control signal for Q3. This configuration allows Q3 to switch on and off rapidly, resulting in the blinking of LED D3. The rate of blinking is determined by the time constants associated with the capacitors and resistors in the multivibrator circuit, which can be adjusted to suit specific application requirements.

Overall, this circuit design provides an effective method for monitoring fuse integrity through a simple visual indicator, enhancing safety and reliability in electronic systems. The implementation of an automatic status indicator for fuses can be particularly beneficial in applications where immediate feedback on fuse condition is critical.Here is the circuit diagram of a fuse that has an automatic status indicator. This circuit can be added to circuit that operates from 12V DC. As long as the fuse is intact, the LED D3 will glow continuously and when the fuse blows off the LED will start and continue blinking. The first part of the circuit includes an astable multivibrator built ar ound transistors Q1 and Q2. The output of the multivibrator is coupled to the base of Q3 via diode D2. When the fuse is intact the base of Q3 will be pulled to a positive voltage by the resistor R5. The transistor will be ON and the LED D3 remains glowing. When the fuse of blown off, the base of Q3 will no longer be pulled to positive voltage and now the only biasing available at the base of Q3 will be the output from the astable multivibrator. Now the transistor Q3 will start switching in the frequency of astable multivibrator and the LED will blink in accordance.

🔗 External reference

The circuit operates on a 12V DC supply, making it suitable for various automotive and electronic applications. The astable multivibrator, formed by transistors Q1 and Q2, generates a square wave output that toggles between high and low states. This oscillation is crucial for the blinking function of the LED, providing a visual indication of the fuse status.

In the circuit, when the fuse is functional, the continuous current flow through the LED D3 is maintained, indicating normal operation. The inclusion of diode D2 ensures that the output from the astable multivibrator does not interfere with the biasing of Q3 when the fuse is intact. Resistor R5 plays a vital role in establishing the base current for Q3, ensuring it remains in the conductive state.

Upon fuse failure, the absence of a positive voltage at the base of Q3 leads to a change in its operating state. The astable multivibrator's output now becomes the primary control signal for Q3. This configuration allows Q3 to switch on and off rapidly, resulting in the blinking of LED D3. The rate of blinking is determined by the time constants associated with the capacitors and resistors in the multivibrator circuit, which can be adjusted to suit specific application requirements.

Overall, this circuit design provides an effective method for monitoring fuse integrity through a simple visual indicator, enhancing safety and reliability in electronic systems. The implementation of an automatic status indicator for fuses can be particularly beneficial in applications where immediate feedback on fuse condition is critical.Here is the circuit diagram of a fuse that has an automatic status indicator. This circuit can be added to circuit that operates from 12V DC. As long as the fuse is intact, the LED D3 will glow continuously and when the fuse blows off the LED will start and continue blinking. The first part of the circuit includes an astable multivibrator built ar ound transistors Q1 and Q2. The output of the multivibrator is coupled to the base of Q3 via diode D2. When the fuse is intact the base of Q3 will be pulled to a positive voltage by the resistor R5. The transistor will be ON and the LED D3 remains glowing. When the fuse of blown off, the base of Q3 will no longer be pulled to positive voltage and now the only biasing available at the base of Q3 will be the output from the astable multivibrator. Now the transistor Q3 will start switching in the frequency of astable multivibrator and the LED will blink in accordance.

🔗 External reference