Heater control

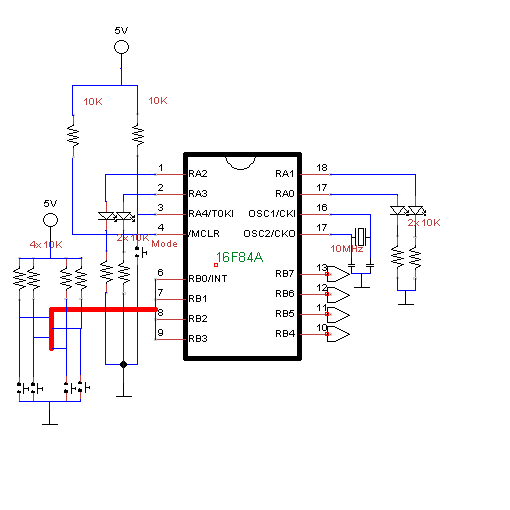

This proportional control crystal oven heater utilizes lead/lag compensation to achieve rapid setting. The time constant can be adjusted using resistor R4 and the compensating resistor R5. It is advisable to use a regulated supply for Q2 if it is located inside the oven to maintain a temperature of 0 °C.

This crystal oven heater circuit incorporates a proportional control mechanism to maintain precise temperature regulation for crystal oscillators. The use of lead/lag compensation allows for improved response times, ensuring that temperature fluctuations are minimized and that the heater quickly reaches the desired operating temperature.

The time constant of the system, which affects how quickly the heater responds to changes in temperature, is adjustable through resistor R4. This provides flexibility in tuning the system to specific requirements, allowing for optimization based on the thermal characteristics of the oven and the crystal being heated. Additionally, the compensating resistor R5 plays a critical role in stabilizing the feedback loop, further enhancing the control performance.

For scenarios where the temperature sensor Q2 is situated within the oven, it is crucial to implement a regulated power supply. This ensures that the sensor operates accurately at lower temperatures, such as 0 °C, without being affected by fluctuations in the supply voltage. A regulated supply maintains consistent performance, which is vital for the stability of the crystal oscillator.

Overall, the design of this proportional control crystal oven heater emphasizes precision, adaptability, and reliability, making it suitable for applications where temperature control is critical for the performance of electronic components.This proportional control crystal oven heater uses lead/lag compensation for fast setting. The time constant is changed with R4 and compensating resistor R5 If Q2 is inside the oven, a regulated supply is recommended for 0 °C. control.

This crystal oven heater circuit incorporates a proportional control mechanism to maintain precise temperature regulation for crystal oscillators. The use of lead/lag compensation allows for improved response times, ensuring that temperature fluctuations are minimized and that the heater quickly reaches the desired operating temperature.

The time constant of the system, which affects how quickly the heater responds to changes in temperature, is adjustable through resistor R4. This provides flexibility in tuning the system to specific requirements, allowing for optimization based on the thermal characteristics of the oven and the crystal being heated. Additionally, the compensating resistor R5 plays a critical role in stabilizing the feedback loop, further enhancing the control performance.

For scenarios where the temperature sensor Q2 is situated within the oven, it is crucial to implement a regulated power supply. This ensures that the sensor operates accurately at lower temperatures, such as 0 °C, without being affected by fluctuations in the supply voltage. A regulated supply maintains consistent performance, which is vital for the stability of the crystal oscillator.

Overall, the design of this proportional control crystal oven heater emphasizes precision, adaptability, and reliability, making it suitable for applications where temperature control is critical for the performance of electronic components.This proportional control crystal oven heater uses lead/lag compensation for fast setting. The time constant is changed with R4 and compensating resistor R5 If Q2 is inside the oven, a regulated supply is recommended for 0 °C. control.