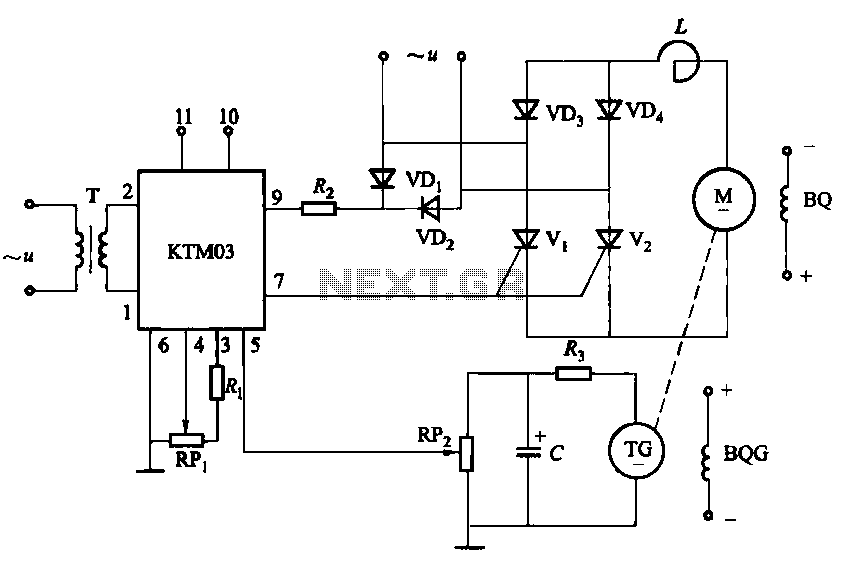

KTM03 type for single-phase half-controlled rectifier circuit

The adjustment potentiometer for the Raspberry Pi can modify the conduction angle of the thyristor VI and V2, which in turn adjusts the speed of the DC motor M. The speed feedback circuit is implemented using a tachometer generator (TG) and a potentiometer (RP2) to fine-tune the feedback amount, effectively creating a closed-loop control system.

The circuit operates by utilizing an adjustment potentiometer connected to the Raspberry Pi, which allows for real-time modifications to the conduction angles of the thyristors VI and V2. This adjustment directly influences the power delivered to the DC motor M, thereby controlling its speed. The thyristors act as electronic switches that can be turned on and off at specific intervals, determined by the conduction angle, which is the duration for which they remain on during each cycle of the AC waveform.

The speed feedback mechanism is critical for maintaining the desired motor speed. It employs a tachometer generator (TG) that produces a voltage proportional to the motor's rotational speed. This voltage serves as feedback to the control system. The feedback signal is then processed through a potentiometer (RP2), which allows for fine adjustments to the feedback level. By tuning RP2, the system can be calibrated to ensure that the feedback is accurate and responsive to changes in motor speed.

This configuration establishes a closed-loop control system, where the actual speed of the motor is continuously monitored and compared to the desired speed set by the user through the potentiometer. If discrepancies arise between the desired and actual speeds, the control system automatically adjusts the conduction angles of the thyristors to correct the motor speed, ensuring stable and efficient operation. The integration of these components results in a robust and adaptable motor control solution suitable for various applications.Adjustment potentiometer RPi, can change the thyristor VI, V2 conduction angle, that is changing the DC motor M speed. Speed feedback circuit is [by tachometer generator TG and potentiometer RP2 (to adjust the amount of feedback)], in fact, is now closed loop control.

The circuit operates by utilizing an adjustment potentiometer connected to the Raspberry Pi, which allows for real-time modifications to the conduction angles of the thyristors VI and V2. This adjustment directly influences the power delivered to the DC motor M, thereby controlling its speed. The thyristors act as electronic switches that can be turned on and off at specific intervals, determined by the conduction angle, which is the duration for which they remain on during each cycle of the AC waveform.

The speed feedback mechanism is critical for maintaining the desired motor speed. It employs a tachometer generator (TG) that produces a voltage proportional to the motor's rotational speed. This voltage serves as feedback to the control system. The feedback signal is then processed through a potentiometer (RP2), which allows for fine adjustments to the feedback level. By tuning RP2, the system can be calibrated to ensure that the feedback is accurate and responsive to changes in motor speed.

This configuration establishes a closed-loop control system, where the actual speed of the motor is continuously monitored and compared to the desired speed set by the user through the potentiometer. If discrepancies arise between the desired and actual speeds, the control system automatically adjusts the conduction angles of the thyristors to correct the motor speed, ensuring stable and efficient operation. The integration of these components results in a robust and adaptable motor control solution suitable for various applications.Adjustment potentiometer RPi, can change the thyristor VI, V2 conduction angle, that is changing the DC motor M speed. Speed feedback circuit is [by tachometer generator TG and potentiometer RP2 (to adjust the amount of feedback)], in fact, is now closed loop control.