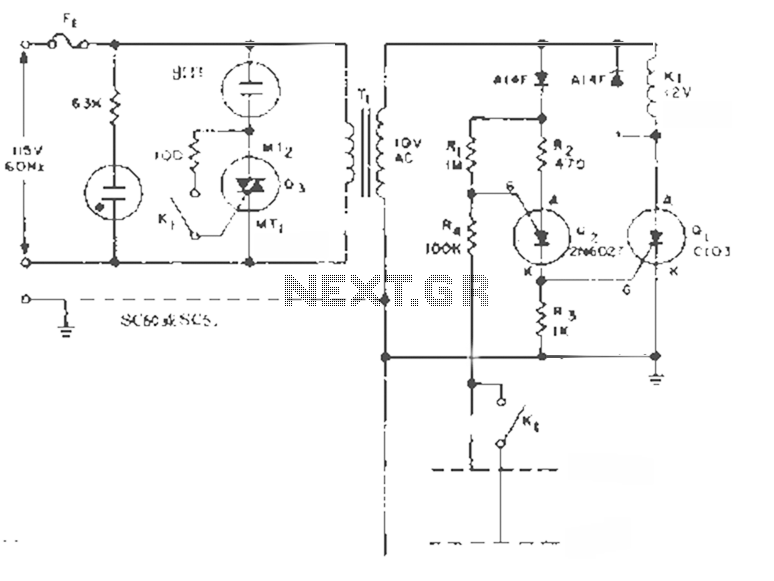

Level controller circuit

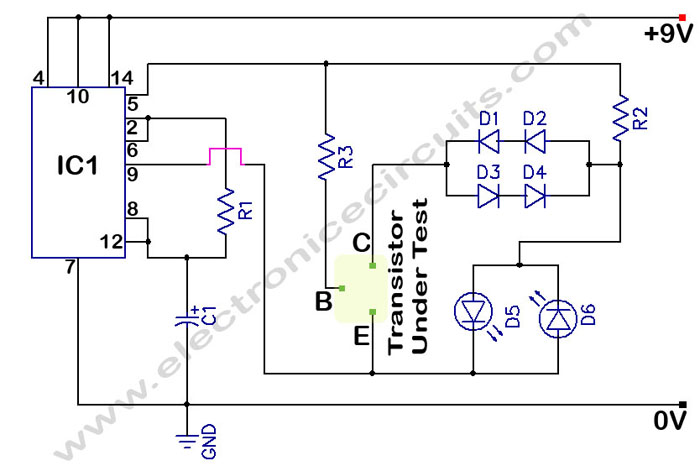

This circuit is designed to maintain the liquid level between two fixed points. By transforming the K1 contacts off the case, it can perform filling or extraction operations in two modes. The load can be either an AC motor or a solenoid-operated valve. The liquid level is detected by two probes, which measure a high level and a low level. By substituting Q3 to control the electrode of the normally open contact with that of the normally closed contact, logic inversion can be implemented (indicating that the container is full).

This circuit employs a liquid level control system that integrates two probes to detect the liquid levels in a container. The probes are positioned at predetermined heights to signify the high and low levels of the liquid. When the liquid reaches the high-level probe, the circuit triggers a response to stop the filling operation, while the low-level probe signals the need to initiate filling when the liquid drops below this threshold.

The K1 relay serves as a critical component in this setup, allowing for the switching between filling and extraction modes. When the relay contacts are configured for filling, the circuit activates either an AC motor or a solenoid valve to introduce liquid into the container. Conversely, when configured for extraction, the relay directs the motor or valve to remove liquid from the container.

The substitution of Q3 to control the normally closed contact instead of the normally open contact introduces an inversion logic to the circuit. This change means that when the container reaches the full state, the circuit will deactivate the filling mechanism by opening the normally closed contact, thereby preventing overflow.

Overall, this circuit provides a robust solution for maintaining liquid levels in various applications, ensuring efficient operation through automated control based on precise level detection. The use of an AC motor or solenoid valve allows for flexibility in operation, making it suitable for diverse industrial or domestic environments.This circuit is used to maintain the level between two fixed points. Just transform K1 contacts off the case, it can be filling or extraction work in two ways. Load can use AC motor or solenoid-operated valve. The liquid level is detected by the two probes to achieve a metal, a measurement of high level. Another measure low level. Substituted Q3 control electrode of the normally open contact with the normally closed contact, you can implement the logic inversion (the container is full).

This circuit employs a liquid level control system that integrates two probes to detect the liquid levels in a container. The probes are positioned at predetermined heights to signify the high and low levels of the liquid. When the liquid reaches the high-level probe, the circuit triggers a response to stop the filling operation, while the low-level probe signals the need to initiate filling when the liquid drops below this threshold.

The K1 relay serves as a critical component in this setup, allowing for the switching between filling and extraction modes. When the relay contacts are configured for filling, the circuit activates either an AC motor or a solenoid valve to introduce liquid into the container. Conversely, when configured for extraction, the relay directs the motor or valve to remove liquid from the container.

The substitution of Q3 to control the normally closed contact instead of the normally open contact introduces an inversion logic to the circuit. This change means that when the container reaches the full state, the circuit will deactivate the filling mechanism by opening the normally closed contact, thereby preventing overflow.

Overall, this circuit provides a robust solution for maintaining liquid levels in various applications, ensuring efficient operation through automated control based on precise level detection. The use of an AC motor or solenoid valve allows for flexibility in operation, making it suitable for diverse industrial or domestic environments.This circuit is used to maintain the level between two fixed points. Just transform K1 contacts off the case, it can be filling or extraction work in two ways. Load can use AC motor or solenoid-operated valve. The liquid level is detected by the two probes to achieve a metal, a measurement of high level. Another measure low level. Substituted Q3 control electrode of the normally open contact with the normally closed contact, you can implement the logic inversion (the container is full).