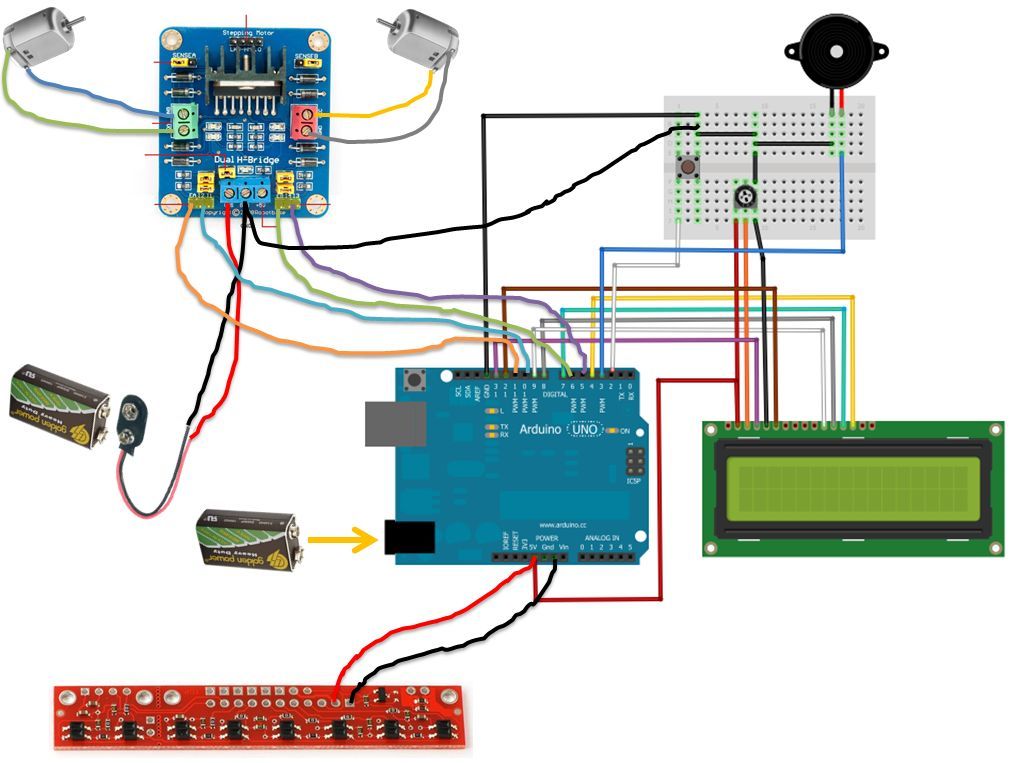

Line Following Robot

To modify the servomotors, first remove the four screws securing the servo casing and disassemble it completely. Carefully extract the electronic components while retaining only the wiring.

Modifying servomotors involves a systematic approach to disassembly and reconfiguration of the internal components. The initial step is to unscrew the four screws that hold the servo casing together, which typically requires a small Phillips screwdriver. After removing the screws, the servo can be gently pried apart to access the internal mechanism.

Once disassembled, attention should be directed towards the electronic components housed within the servo. It is essential to carefully detach these components while ensuring that the wiring remains intact for future modifications. The wires are crucial as they will connect the modified servo to a control system or microcontroller.

After the electronics have been removed, modifications can be made to enhance the performance of the servomotor. This may include upgrading the motor for better torque or speed, altering the feedback mechanism, or integrating new control circuitry. It is critical to ensure that any modifications align with the intended application of the servomotor, whether it be for robotics, automation, or other applications.

Once modifications are complete, the servo should be reassembled, ensuring that all components fit securely within the casing. The final step involves testing the modified servomotor to verify that it operates as intended and meets the desired specifications. Proper testing will help identify any issues that may arise from the modifications and allow for further adjustments if necessary.How to Mod the Servomotors (look at the pictures) Remove the four screws from the servo and take it all apart. Remove the electronics keeping only the wires from th.. 🔗 External reference

Modifying servomotors involves a systematic approach to disassembly and reconfiguration of the internal components. The initial step is to unscrew the four screws that hold the servo casing together, which typically requires a small Phillips screwdriver. After removing the screws, the servo can be gently pried apart to access the internal mechanism.

Once disassembled, attention should be directed towards the electronic components housed within the servo. It is essential to carefully detach these components while ensuring that the wiring remains intact for future modifications. The wires are crucial as they will connect the modified servo to a control system or microcontroller.

After the electronics have been removed, modifications can be made to enhance the performance of the servomotor. This may include upgrading the motor for better torque or speed, altering the feedback mechanism, or integrating new control circuitry. It is critical to ensure that any modifications align with the intended application of the servomotor, whether it be for robotics, automation, or other applications.

Once modifications are complete, the servo should be reassembled, ensuring that all components fit securely within the casing. The final step involves testing the modified servomotor to verify that it operates as intended and meets the desired specifications. Proper testing will help identify any issues that may arise from the modifications and allow for further adjustments if necessary.How to Mod the Servomotors (look at the pictures) Remove the four screws from the servo and take it all apart. Remove the electronics keeping only the wires from th.. 🔗 External reference