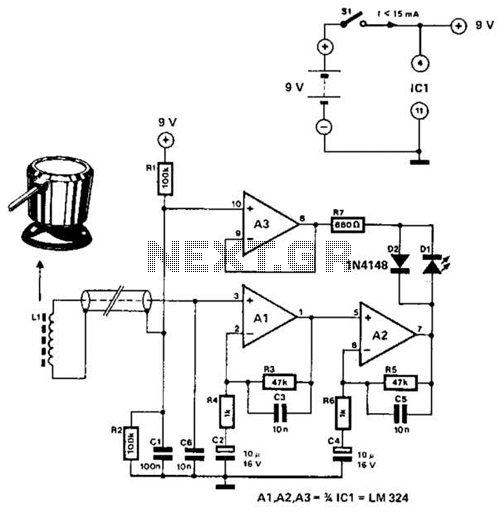

Linear Inductance Meter Circuit

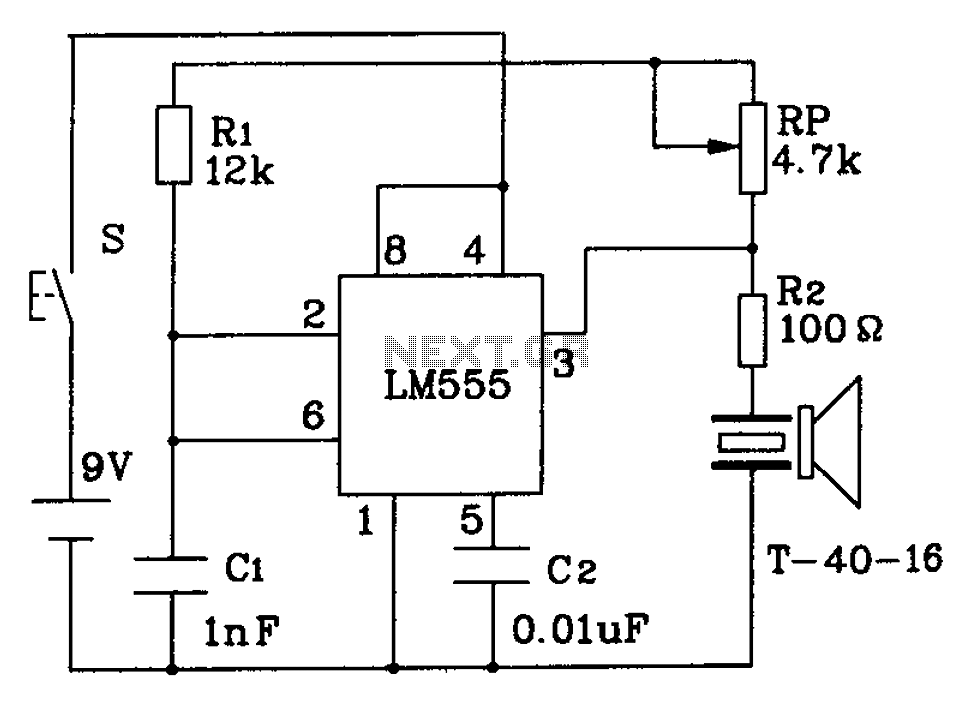

The circuit utilizes the principle that in an RL circuit, the pulse width across the inductor is proportional to the inductance. This circuit indirectly measures the inductance using a digital voltmeter (DVM). The measurement range is approximately 5 to 250 microhenries (uH).

The described circuit leverages the relationship between inductance and the time constant in an RL circuit to provide a measurement of inductance via a digital voltmeter. In this configuration, the inductor is subjected to a step voltage, causing a current to rise according to the time constant determined by the inductance (L) and the resistance (R) in the circuit. The pulse width observed across the inductor is directly related to the inductance value, allowing for an indirect measurement.

To implement this circuit, the following components are typically required: an inductor whose inductance is to be measured, a resistor to form the RL circuit, a switch to apply a voltage pulse, and a digital voltmeter to read the resultant voltage across the inductor. The resistor value can be selected to ensure that the time constant (τ = L/R) is within a range that can be accurately measured by the DVM.

The output voltage across the inductor during the pulse will vary with the inductance value. As the inductance increases, the pulse width will also increase, which can be calibrated to correspond to specific inductance values. The DVM is used to capture this voltage, which can then be translated into a corresponding inductance value within the specified range of 5 to 250 uH.

For accurate readings, it is essential to account for factors such as the resistance of the leads, the characteristics of the inductor, and the response time of the DVM. Calibration against known inductance standards can also enhance measurement precision. Overall, this circuit provides a practical means to measure inductance in a non-invasive manner, suitable for various applications in electronics and testing environments. Using the fact that in an RL circuit, the pulse width seen across the inductor is proportional to the inductance, this circuit reads this indirectly on a DVM. The range is about 5 to 250 uH.

The described circuit leverages the relationship between inductance and the time constant in an RL circuit to provide a measurement of inductance via a digital voltmeter. In this configuration, the inductor is subjected to a step voltage, causing a current to rise according to the time constant determined by the inductance (L) and the resistance (R) in the circuit. The pulse width observed across the inductor is directly related to the inductance value, allowing for an indirect measurement.

To implement this circuit, the following components are typically required: an inductor whose inductance is to be measured, a resistor to form the RL circuit, a switch to apply a voltage pulse, and a digital voltmeter to read the resultant voltage across the inductor. The resistor value can be selected to ensure that the time constant (τ = L/R) is within a range that can be accurately measured by the DVM.

The output voltage across the inductor during the pulse will vary with the inductance value. As the inductance increases, the pulse width will also increase, which can be calibrated to correspond to specific inductance values. The DVM is used to capture this voltage, which can then be translated into a corresponding inductance value within the specified range of 5 to 250 uH.

For accurate readings, it is essential to account for factors such as the resistance of the leads, the characteristics of the inductor, and the response time of the DVM. Calibration against known inductance standards can also enhance measurement precision. Overall, this circuit provides a practical means to measure inductance in a non-invasive manner, suitable for various applications in electronics and testing environments. Using the fact that in an RL circuit, the pulse width seen across the inductor is proportional to the inductance, this circuit reads this indirectly on a DVM. The range is about 5 to 250 uH.