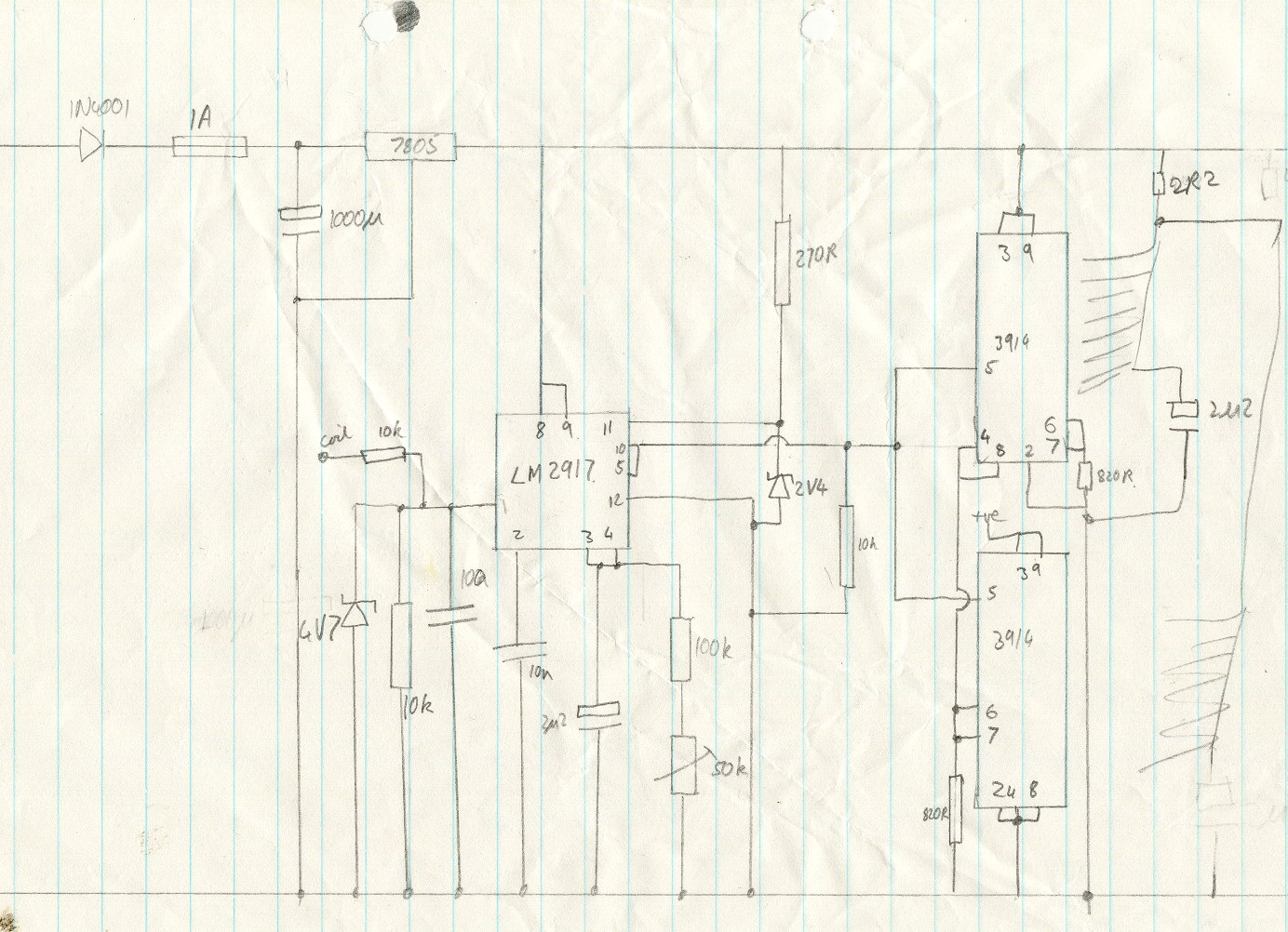

LM2917 frequency to voltage converter

This circuit utilizes an LM2917 frequency-to-voltage converter. The input is connected to the low voltage side of the ignition coil, with various components designed to produce a full-scale output at 6000 RPM, corresponding to 12000 ignition pulses per minute, or 200 Hz. The resulting voltage is then fed to two cascaded LM3914 bar graph drivers. The configuration includes two red LEDs for the top two segments, three orange LEDs, and the remainder are green. The transition between the two bar graph drivers occurs at 3000-3300 RPM, closely aligning with the engine's optimal performance point. To enhance visibility, the right-hand LEDs are set to be slightly brighter than the left-hand ones. A printed circuit board (PCB) was etched using transfers for the pads and a pen for the traces. Holes were drilled with a modified paperclip used as a drill bit, and soldering was completed using a small plastic hand drill.

This circuit design employs the LM2917 frequency-to-voltage converter, which effectively translates the frequency of ignition pulses from the ignition coil into a proportional voltage output. The connection to the low voltage side of the ignition coil ensures accurate readings of engine RPM by capturing the frequency of the ignition events. The design aims for a full-scale output at 6000 RPM, which translates to 12000 pulses per minute, resulting in a frequency of 200 Hz.

The voltage output from the LM2917 is directed to two LM3914 bar graph drivers, which are configured to visually represent the engine RPM through a series of LEDs. The choice of using two red LEDs for the top segments serves to indicate critical RPM thresholds, while three orange LEDs provide a transitional warning zone. The remaining green LEDs indicate normal operating conditions. The design incorporates a deliberate transition point between the two bar graph drivers at 3000-3300 RPM, which is strategically aligned with the engine's optimal performance range. This not only enhances the usability of the display but also allows for immediate visual feedback to the operator regarding engine performance.

The PCB design process involved etching techniques, utilizing transfer methods for pad placement and manual pen tracing for circuit pathways. This approach ensures precision in the layout, while the drilling of holes for components was executed with a modified paperclip, demonstrating a resourceful method for achieving necessary component placements. Soldering was performed with a small hand drill, indicating a hands-on, practical approach to the assembly of the circuit. Overall, this circuit design provides a reliable and effective means of monitoring engine RPM through visual indicators, enhancing the operational efficiency of the engine.This circuit uses an LM2917 frequency to voltage converter. The input was connected to the low voltage side of the ignition coil, and the various components around it design to produce a full scale output at 6000rpm, which corresponds to 12000 ignition pulses per minute, or 200Hz. The voltage from this was then fed to 2 cascaded LM3914 bargraph dr ivers. I had 2 red LEDs for the top two segments, then 3 orange leds, and the rest were green. The "join" between two bargraph drivers was at 3000-3300rpm, which corresponded closely with the point at which the engine started to work well, so I set up the right-hand LEDs slightly brighter than the left hand ones. I etched a PCB (ahh the quality of the documentation!), using transfers for the pads and a pen for the lines, drilled the holes (with a snipped off paperclip for a drill bit) with a small plastic handdrill, and got soldering.

🔗 External reference

This circuit design employs the LM2917 frequency-to-voltage converter, which effectively translates the frequency of ignition pulses from the ignition coil into a proportional voltage output. The connection to the low voltage side of the ignition coil ensures accurate readings of engine RPM by capturing the frequency of the ignition events. The design aims for a full-scale output at 6000 RPM, which translates to 12000 pulses per minute, resulting in a frequency of 200 Hz.

The voltage output from the LM2917 is directed to two LM3914 bar graph drivers, which are configured to visually represent the engine RPM through a series of LEDs. The choice of using two red LEDs for the top segments serves to indicate critical RPM thresholds, while three orange LEDs provide a transitional warning zone. The remaining green LEDs indicate normal operating conditions. The design incorporates a deliberate transition point between the two bar graph drivers at 3000-3300 RPM, which is strategically aligned with the engine's optimal performance range. This not only enhances the usability of the display but also allows for immediate visual feedback to the operator regarding engine performance.

The PCB design process involved etching techniques, utilizing transfer methods for pad placement and manual pen tracing for circuit pathways. This approach ensures precision in the layout, while the drilling of holes for components was executed with a modified paperclip, demonstrating a resourceful method for achieving necessary component placements. Soldering was performed with a small hand drill, indicating a hands-on, practical approach to the assembly of the circuit. Overall, this circuit design provides a reliable and effective means of monitoring engine RPM through visual indicators, enhancing the operational efficiency of the engine.This circuit uses an LM2917 frequency to voltage converter. The input was connected to the low voltage side of the ignition coil, and the various components around it design to produce a full scale output at 6000rpm, which corresponds to 12000 ignition pulses per minute, or 200Hz. The voltage from this was then fed to 2 cascaded LM3914 bargraph dr ivers. I had 2 red LEDs for the top two segments, then 3 orange leds, and the rest were green. The "join" between two bargraph drivers was at 3000-3300rpm, which corresponded closely with the point at which the engine started to work well, so I set up the right-hand LEDs slightly brighter than the left hand ones. I etched a PCB (ahh the quality of the documentation!), using transfers for the pads and a pen for the lines, drilled the holes (with a snipped off paperclip for a drill bit) with a small plastic handdrill, and got soldering.

🔗 External reference