Motor vehicle steering flasher 12

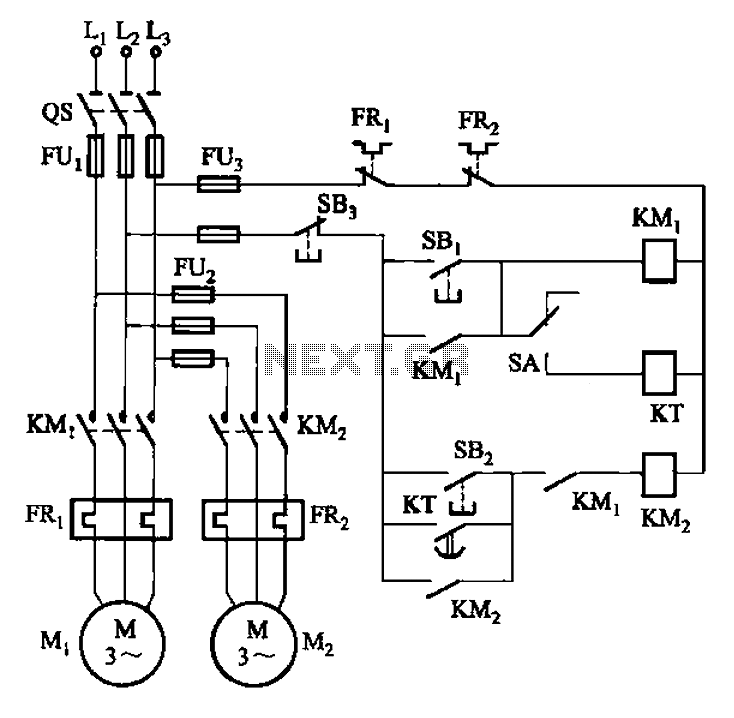

The motor vehicle steering flasher described in the example utilizes high-power transistors as electronic switches, and the circuit is simple and easy to construct. The motor vehicle steering flasher consists of the flash circuit with resistors R1-R3, a capacitor C, a diode VD, and transistors V1 and V2, as illustrated in Figure 7-21. Switch S functions as the vehicle turn signal switch, while HL1 and HL2 represent the left and right turn signals, respectively. When the turn signal switch S is in the center position, the oscillator circuit formed by V1, V2, and the external RC components remains inactive. By placing switch S in the L or R position, the oscillation circuit becomes operational, causing V2 to conduct intermittently at a specific frequency, resulting in the flashing of HL1 or HL2. For component selection, resistors R1-R3 should be 1/4W carbon film or metal film types. Capacitor C should be a 25V electrolytic capacitor. Diode VD should be an 1N5402 silicon rectifier diode. Transistor V1 can be either a 3DGl2 or S8050 silicon NPN transistor, while V2 should be a 3AD30 germanium PNP transistor.

The motor vehicle steering flasher circuit serves as a critical component in automotive signaling systems, enabling drivers to communicate their intent to turn or change lanes effectively. The circuit operates by utilizing a simple oscillator configuration that alternates the current through the turn signal lamps, creating a flashing effect that is easily recognizable to other road users.

The resistors R1-R3 are integral in setting the timing characteristics of the oscillator circuit. The values of these resistors can be adjusted to modify the flash rate of the turn signals, allowing for customization based on vehicle requirements or regulatory standards. The choice of 1/4W carbon film or metal film resistors ensures reliability and stability in performance.

Capacitor C plays a vital role in the timing and stability of the oscillation. The use of a 25V electrolytic capacitor is appropriate for this application, providing sufficient voltage rating to handle the circuit's operational demands while maintaining compact size and efficiency.

The diode VD, specifically the 1N5402, is selected for its robustness and ability to handle higher current loads, ensuring that the circuit remains protected from voltage spikes and reverse polarity conditions. This diode is crucial for rectifying the current and allowing for proper operation of the transistors.

Transistors V1 and V2 are pivotal in controlling the oscillation and signal output. The selection of a silicon NPN transistor (3DGl2 or S8050) for V1 provides reliable switching capabilities, while the germanium PNP transistor (3AD30) for V2 allows for effective modulation of the current flow to the turn signal lamps. The combination of these transistors forms a complementary configuration that enhances the efficiency of the circuit.

Overall, the motor vehicle steering flasher circuit exemplifies a straightforward yet effective design that leverages basic electronic components to achieve reliable vehicle signaling. Proper selection and arrangement of the components ensure that the circuit functions correctly, providing essential safety features for automotive applications.The motor vehicle steering flasher described in the example uses high-power transistors as electronic switches, the circuit is simple, easy to make. The working principle The motor vehicle steering flasher is composed of the flash circuit resistors R1-R3.

Capacitor C, diode VD, transistors V1, V2, it is shown in Figure 7-21. S is the vehicle turn signal switch; HLl and HL2 are the left turn signal and right turn signal respectively. Before turning signal switch S (in the center), the oscillator circuit composed of vl, v2, and external RC components does not work. Placing S in the L or R position, the oscillation circuit works, V2 makes intermittent conduction with a certain frequency, Ll or HL2 is flashing.

Component selection RI-R3 selects 1/4W carbon film resistor or metal film resistors. C uses 25V electrolytic capacitors. VD uses lN5402 silicon rectifier diode. VI selects 3DGl2 or S8050 silicon NPN transistor; V2 uses 3AD30 germanium PNP transistors. 🔗 External reference

The motor vehicle steering flasher circuit serves as a critical component in automotive signaling systems, enabling drivers to communicate their intent to turn or change lanes effectively. The circuit operates by utilizing a simple oscillator configuration that alternates the current through the turn signal lamps, creating a flashing effect that is easily recognizable to other road users.

The resistors R1-R3 are integral in setting the timing characteristics of the oscillator circuit. The values of these resistors can be adjusted to modify the flash rate of the turn signals, allowing for customization based on vehicle requirements or regulatory standards. The choice of 1/4W carbon film or metal film resistors ensures reliability and stability in performance.

Capacitor C plays a vital role in the timing and stability of the oscillation. The use of a 25V electrolytic capacitor is appropriate for this application, providing sufficient voltage rating to handle the circuit's operational demands while maintaining compact size and efficiency.

The diode VD, specifically the 1N5402, is selected for its robustness and ability to handle higher current loads, ensuring that the circuit remains protected from voltage spikes and reverse polarity conditions. This diode is crucial for rectifying the current and allowing for proper operation of the transistors.

Transistors V1 and V2 are pivotal in controlling the oscillation and signal output. The selection of a silicon NPN transistor (3DGl2 or S8050) for V1 provides reliable switching capabilities, while the germanium PNP transistor (3AD30) for V2 allows for effective modulation of the current flow to the turn signal lamps. The combination of these transistors forms a complementary configuration that enhances the efficiency of the circuit.

Overall, the motor vehicle steering flasher circuit exemplifies a straightforward yet effective design that leverages basic electronic components to achieve reliable vehicle signaling. Proper selection and arrangement of the components ensure that the circuit functions correctly, providing essential safety features for automotive applications.The motor vehicle steering flasher described in the example uses high-power transistors as electronic switches, the circuit is simple, easy to make. The working principle The motor vehicle steering flasher is composed of the flash circuit resistors R1-R3.

Capacitor C, diode VD, transistors V1, V2, it is shown in Figure 7-21. S is the vehicle turn signal switch; HLl and HL2 are the left turn signal and right turn signal respectively. Before turning signal switch S (in the center), the oscillator circuit composed of vl, v2, and external RC components does not work. Placing S in the L or R position, the oscillation circuit works, V2 makes intermittent conduction with a certain frequency, Ll or HL2 is flashing.

Component selection RI-R3 selects 1/4W carbon film resistor or metal film resistors. C uses 25V electrolytic capacitors. VD uses lN5402 silicon rectifier diode. VI selects 3DGl2 or S8050 silicon NPN transistor; V2 uses 3AD30 germanium PNP transistors. 🔗 External reference