PCB Parametric Audio Equalizer

This project is based on the parametric equalizer proposed by Elektor in the late 1980s or early 1990s and later published in the book "Creations Electroniques" in 1993 (Publisher: Publitronic). Their design involved three stereo potentiometers per channel, resulting in numerous cables from the front panel to the circuit board. This complexity can lead to noise issues within the enclosure. To address these challenges and create a more compact unit, the entire design has been integrated onto a single board, including the potentiometers, eliminating the need for additional cabling. A graphic equalizer features one control per band, which adjusts gain, while a parametric equalizer includes three controls: gain, frequency, and width. Unlike graphic equalizers that require multiple bands for sound correction, parametric equalizers offer greater accuracy, typically using only one to three filters in series. Several modifications have been implemented to enhance this design. Firstly, it is an all-SMD (Surface Mount Device) board, which simplifies and reduces manufacturing costs. This design choice is essential due to limited clearance with the front panel. Additionally, multiple PCBs will be stacked adjacent to one another for the various filtering stages (usually three, as suggested by Elektor), necessitating a compact PCB layout without extending the size or spacing of the potentiometers. The alternative would involve using DIL (Dual In-Line) circuits and multiple stacked PCBs, which is neither practical nor cost-effective.

The parametric equalizer circuit is designed to provide precise control over audio frequencies, allowing for enhanced sound customization. The integration of the potentiometers directly onto the PCB minimizes signal degradation that can occur with long cable runs, thereby reducing noise and improving overall sound quality. Each potentiometer is strategically placed to ensure ease of access while maintaining a compact layout. The SMD technology utilized in this design not only streamlines the assembly process but also contributes to a smaller footprint, making it suitable for various applications where space is a constraint.

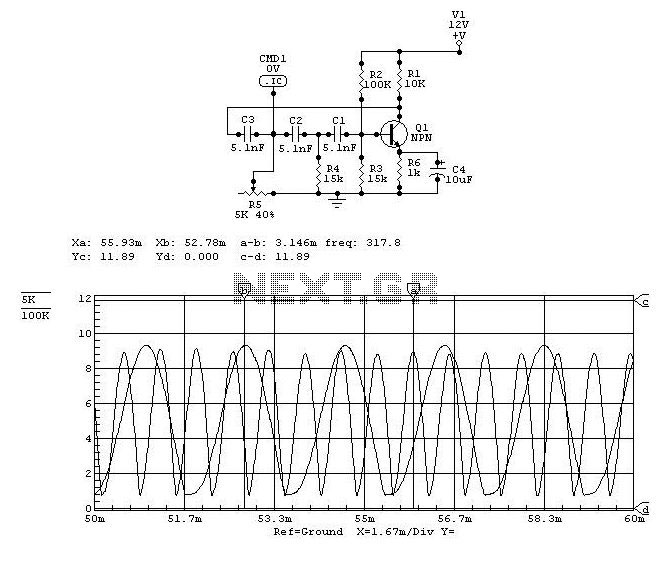

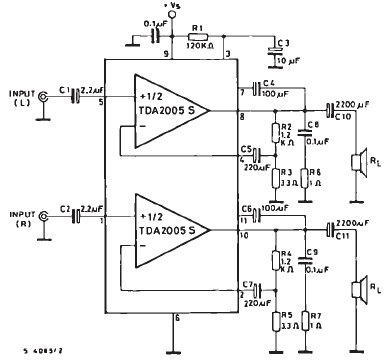

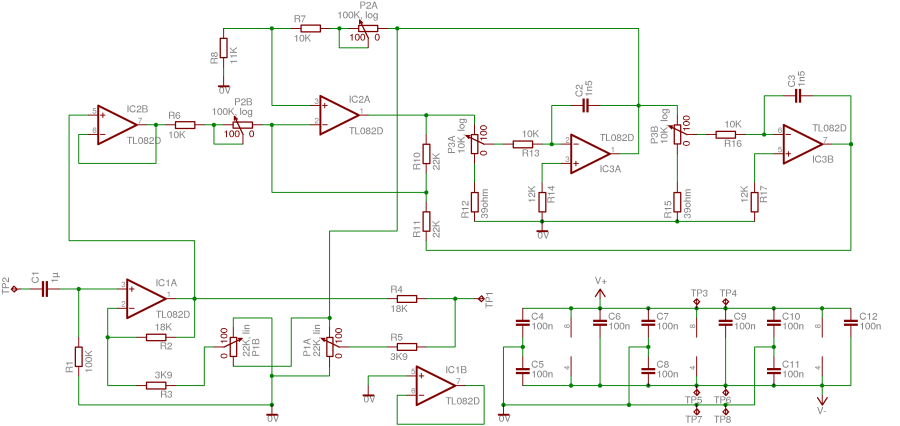

The circuit employs a series of operational amplifiers configured to create the desired filtering characteristics. The gain control adjusts the amplitude of the audio signal, while the frequency control allows users to select the center frequency of the filter. The width control, often referred to as Q, determines the bandwidth of the frequency being adjusted, enabling users to fine-tune the audio output to their preference. The stacked PCB design facilitates the implementation of multiple filtering stages, which can be tailored to target specific frequency ranges for more detailed sound shaping.

In summary, this compact, all-SMD parametric equalizer design significantly improves upon traditional designs by reducing complexity, enhancing sound quality, and providing users with precise control over their audio signals. The modifications made to the original design not only address practical assembly challenges but also optimize the performance and usability of the equalizer.This project is based on the parametric equalizer proposed by Elektor in the late 80s or early 90s and later published in the book "Creations electroniques" in 1993 (Publisher: Publitronic). Their design involved three stereo potentiometers per channel, which means a lot of cables from the front panel to the circuit board.

It`s quite tiedous to build and IMHO prone to noise from within the enclosure. To solve these problems and make the unit more compact I have put everything on a single board, potentiometers included. No more cables! A graphic equaliser has only one control per band: the gain. A parametric equaliser has 3 controls: gain, frequency and width. While a graphic equalizer requires a lot of bands to correct the sound, a parametric equaliser is more acurate and usually only one to three filters are used in series.

Several modifications were made to allow these improvements. First, it`s an all-SMD board: easier and cheaper to build. This is necessary because clearance is limited with the front pannel. More importantly, it is important to realize that several PCBs will be stacked next to each other for the different filtering stages (usually 3, as Elektor says) and therefor we have no space to extend the PCB without spacing the potentiometers too. The only other option would be to use DIL circuits and several stacked PCBs: not very practical or cost effective.

🔗 External reference

The parametric equalizer circuit is designed to provide precise control over audio frequencies, allowing for enhanced sound customization. The integration of the potentiometers directly onto the PCB minimizes signal degradation that can occur with long cable runs, thereby reducing noise and improving overall sound quality. Each potentiometer is strategically placed to ensure ease of access while maintaining a compact layout. The SMD technology utilized in this design not only streamlines the assembly process but also contributes to a smaller footprint, making it suitable for various applications where space is a constraint.

The circuit employs a series of operational amplifiers configured to create the desired filtering characteristics. The gain control adjusts the amplitude of the audio signal, while the frequency control allows users to select the center frequency of the filter. The width control, often referred to as Q, determines the bandwidth of the frequency being adjusted, enabling users to fine-tune the audio output to their preference. The stacked PCB design facilitates the implementation of multiple filtering stages, which can be tailored to target specific frequency ranges for more detailed sound shaping.

In summary, this compact, all-SMD parametric equalizer design significantly improves upon traditional designs by reducing complexity, enhancing sound quality, and providing users with precise control over their audio signals. The modifications made to the original design not only address practical assembly challenges but also optimize the performance and usability of the equalizer.This project is based on the parametric equalizer proposed by Elektor in the late 80s or early 90s and later published in the book "Creations electroniques" in 1993 (Publisher: Publitronic). Their design involved three stereo potentiometers per channel, which means a lot of cables from the front panel to the circuit board.

It`s quite tiedous to build and IMHO prone to noise from within the enclosure. To solve these problems and make the unit more compact I have put everything on a single board, potentiometers included. No more cables! A graphic equaliser has only one control per band: the gain. A parametric equaliser has 3 controls: gain, frequency and width. While a graphic equalizer requires a lot of bands to correct the sound, a parametric equaliser is more acurate and usually only one to three filters are used in series.

Several modifications were made to allow these improvements. First, it`s an all-SMD board: easier and cheaper to build. This is necessary because clearance is limited with the front pannel. More importantly, it is important to realize that several PCBs will be stacked next to each other for the different filtering stages (usually 3, as Elektor says) and therefor we have no space to extend the PCB without spacing the potentiometers too. The only other option would be to use DIL circuits and several stacked PCBs: not very practical or cost effective.

🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713